High-polymer gravel permeable rigid pile and its construction technique

A high-polymer, rigid pile technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of lack of drainage performance, long maintenance time, and difficulty in achieving design strength, shortening the consolidation time, construction The effect of short period and improved drainage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

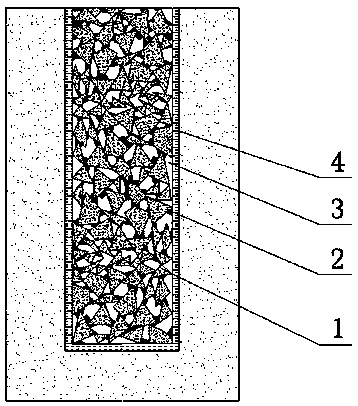

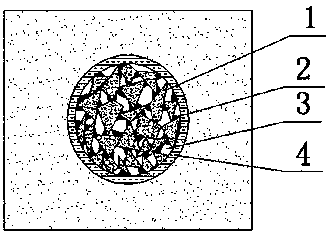

[0026] Such as figure 1 As shown, a polymer gravel permeable rigid pile includes gravel particles 1, and the gravel particles 1 are cemented by a polymer 2 to form a pile structure. The proportion of the polymer 2 and gravel particles 1 needs to be determined according to the Carry out tests to determine the bearing requirements and material properties of the body, but the ratio does not exceed 15:100. Partial gaps 3 between the gravel particles 1 are retained in the pile structure, and the bottom and outer walls of the pile structure are provided with an anti-filter layer 4, and the anti-filter layer 4 is a filter geotextile with certain elasticity. Crushed stone particles 1 are formed by cru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com