Slit-type cold head used for coaxial-type pulse pipe refrigerator and provided with flow guiding structures and manufacturing method

A pulse tube refrigerator, coaxial technology, applied in the direction of refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problem of inability to reduce the empty volume of the inner flow channel of the cold head, deteriorate the heat transfer performance of the cold head, and have no flow guide structure and other issues, to reduce the cross flow with vessels, reduce the void volume, and reduce the flow loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

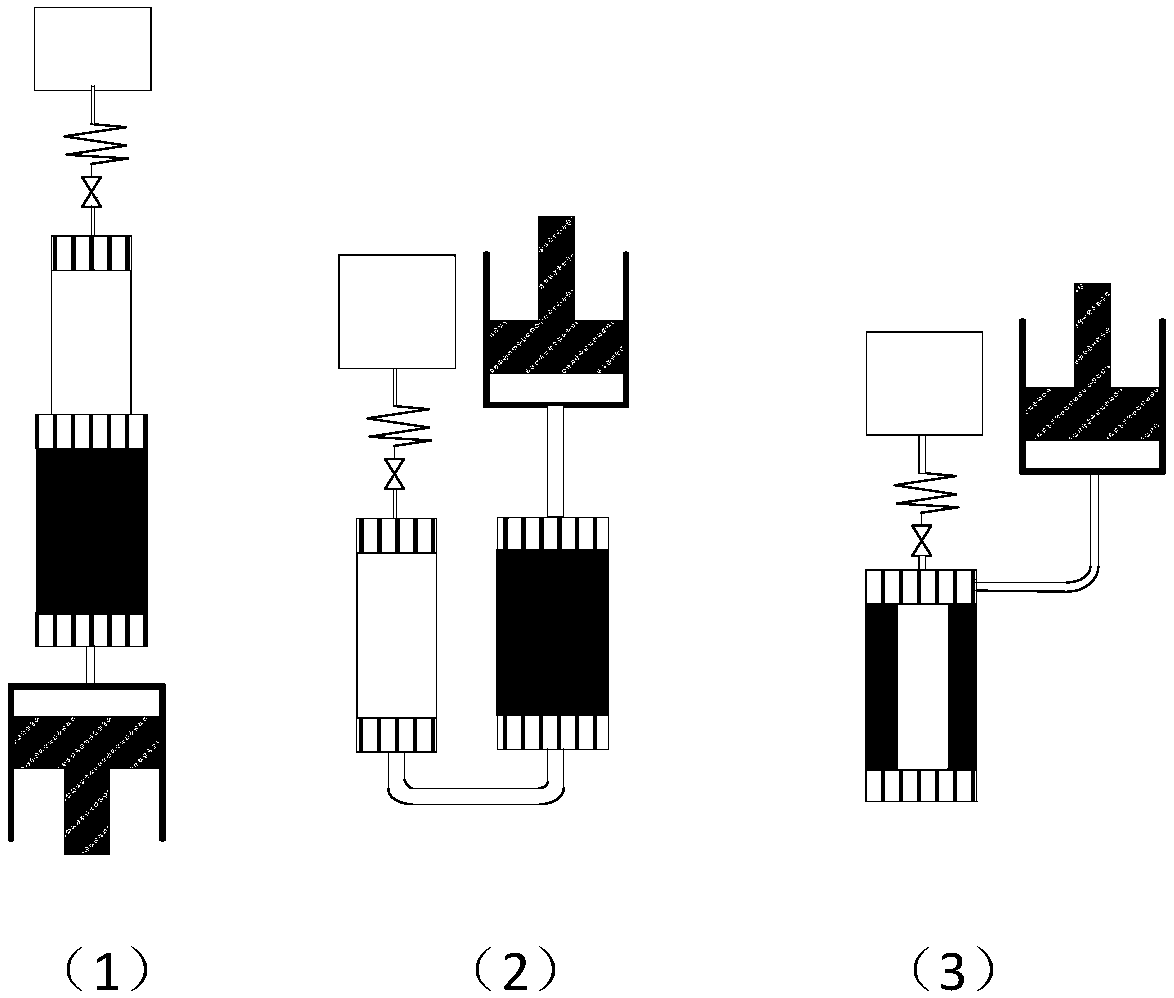

Method used

Image

Examples

Embodiment Construction

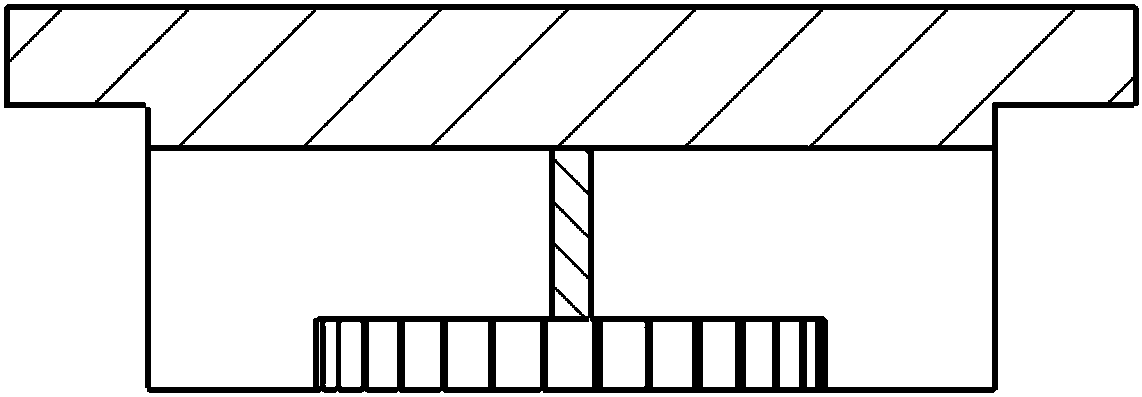

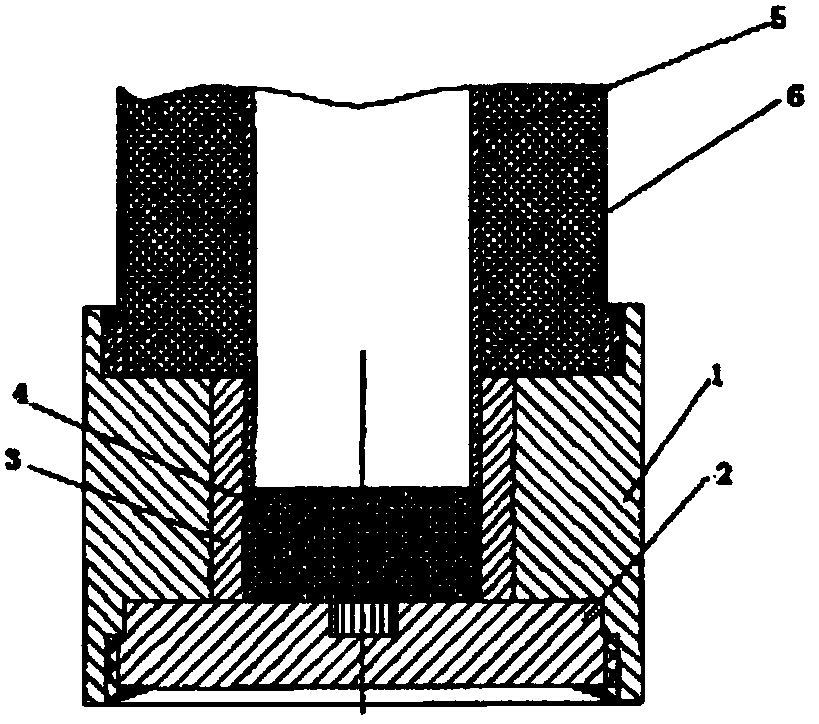

[0025] Attached below Figure 4 And attached Figure 5 The embodiments of the present invention are described in detail: this embodiment is implemented on the premise of the technical solution of the invention, and detailed implementation and specific operation process are provided, but the protection scope of the present invention is not limited to the following embodiments.

[0026] Such as Figure 4 As shown, the present invention includes a cold head main body 1, an anti-deformation pad 3, a red copper wire mesh 4 and a baffle plate 5 and consists of four parts. Corresponding threaded through holes are arranged on the outer side of the large end of the cold head main body 1 and the anti-deformation pad 3, and the threaded holes are simultaneously formed after brazing and finishing. There is a cylindrical groove in the middle of the small end of the cold head main body 1, which is matched with the cold end baffle 5, and serves as a space for filling the copper wire mesh 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com