Bilayer glue stripping process applying flood exposure through acoustic surface wave filter

A technology of surface acoustic wave and peeling process, which is applied in the photoengraving process of pattern surface, photosensitive material processing, microlithography exposure equipment, etc. For independence, complexity of process details, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

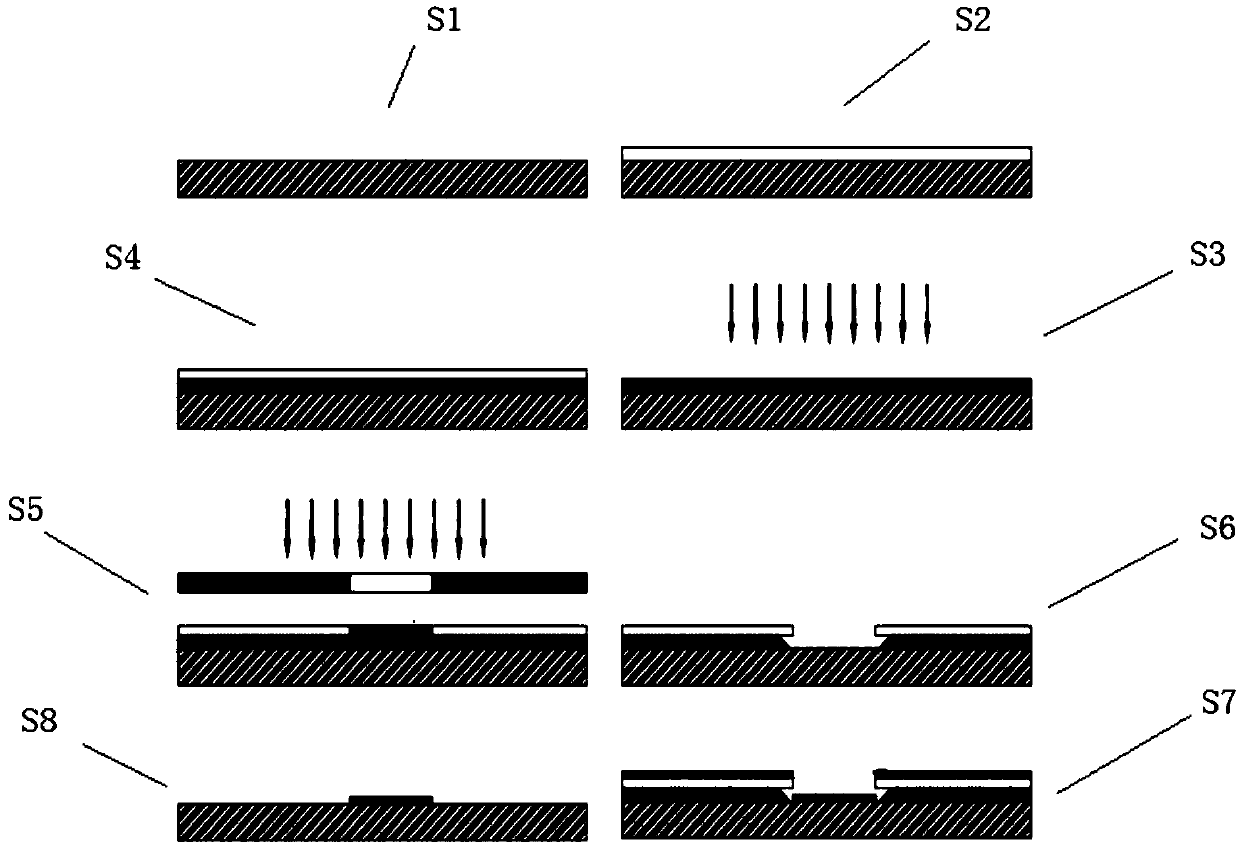

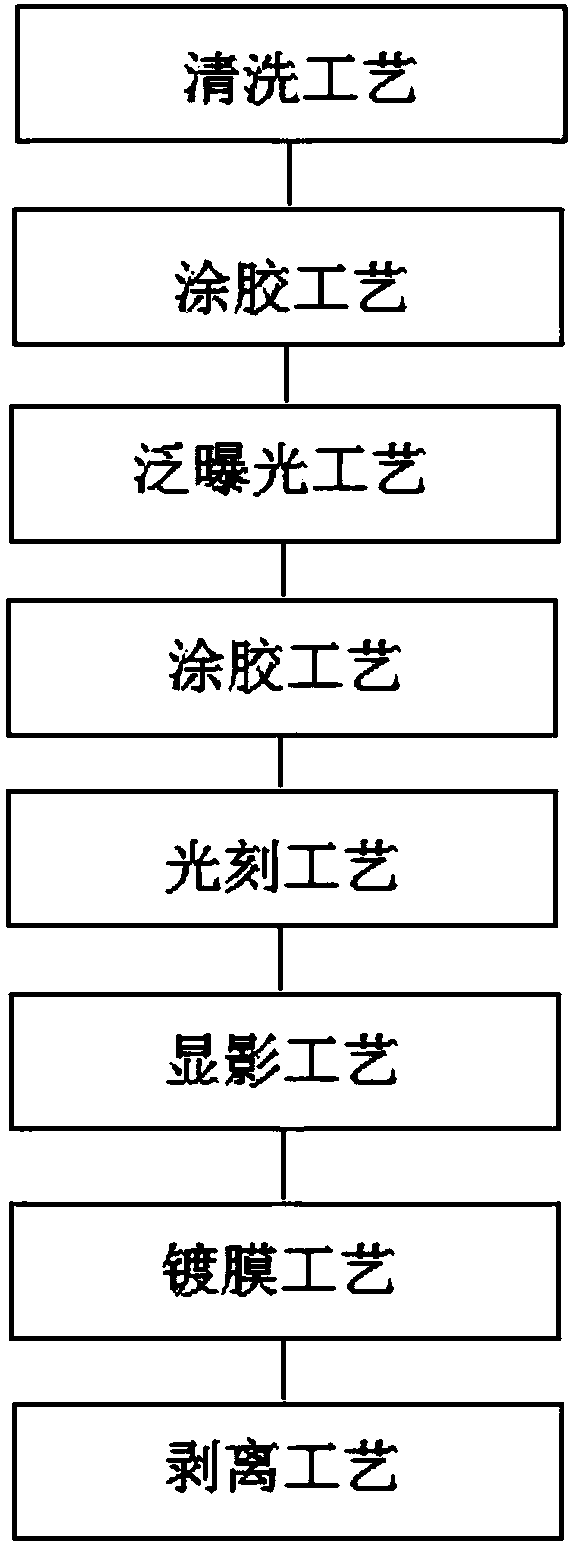

[0026] combine figure 1 , figure 2 As shown, the specific steps of the double-layer adhesive peeling process of applying flood exposure to the surface acoustic wave filter are described in detail as follows.

[0027] Step 1. Cleaning process: cleaning of piezoelectric materials.

[0028] Step 2. Coating process: Spin-coat an ordinary positive photoresist with a viscosity of 49 CPS at a rotational speed of 5000 rpm, and a thickness of about 22000 angstroms.

[0029] Step 3. Pan-exposure treatment: UV flood exposure (full exposure of all non-mask plates without difference on the entire wafer) irradiates the wafer coated with positive photoresist, the photoresist is completely exposed, and the photoresist reacts.

[0030] Step 4. Secondary coating process: In order to prevent the first layer of photoresist from collapsing, spin-coat a positive photoresist with a viscosity of 14CPS at a speed of 3000 rpm (need to be the same as the photoresist with a viscosity of 49CPS used in ...

Embodiment 2

[0039] Step 1. Cleaning process: cleaning of piezoelectric materials.

[0040] Step 2. Coating process: Spin-coat ordinary positive photoresist with a viscosity of 45CPS at a rotational speed of 5500 rpm, and a thickness of about 20000 angstroms.

[0041] Step 3. Pan-exposure treatment: UV flood exposure (full exposure of all non-mask plates without difference on the entire wafer) irradiates the wafer coated with positive photoresist, the photoresist is completely exposed, and the photoresist reacts.

[0042] Step 4. Second coating process: In order to prevent the first layer of photoresist from collapsing, spin-coat a positive photoresist with a viscosity of 13CPS at a speed of 3000 rpm (need to be the same as the photoresist with a viscosity of 45CPS used in the second step) The model is the same as the name of the product, so the same developer can be used), and the thickness of the glue is about 14000 angstroms.

[0043] Step 5. Photolithography process: Ultraviolet rays ...

Embodiment 3

[0048] 1. Cleaning process: Soak in concentrated sulfuric acid + hydrogen peroxide for 4 hours to remove organic matter and metal impurities in the piezoelectric material, and remove tiny particles by rinsing and megasonic cleaning to complete the cleaning of the piezoelectric material wafer.

[0049] 2. Glue coating process: Spin-coat ordinary positive photoresist with a viscosity of 49CPS at a speed of 5000 rpm, heat on a hot plate at 90°C for 90 seconds, and the thickness of the glue is about 22000 angstroms.

[0050] 3. Pan-exposure treatment: Use URE-2000 / 35 deep ultraviolet lithography machine to perform pan-exposure on the piezoelectric material (full exposure of the entire wafer with no mask and no difference), the time is 5 minutes, and the photoresist The exposure is complete and the photoresist reacts.

[0051] 4. Second coating process: In order to prevent the first layer of photoresist from collapsing, spin-coat positive photoresist with a viscosity of 14CPS at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com