On-site monitoring and treating technology for waste biolipid

A bio-grease and treatment technology, applied in the direction of solid waste removal, transportation and packaging, detergent composition, etc., can solve the problems of high output cost, no economic benefit, high investment cost, etc., achieve short reaction cycle, The effect of low cost and low investment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

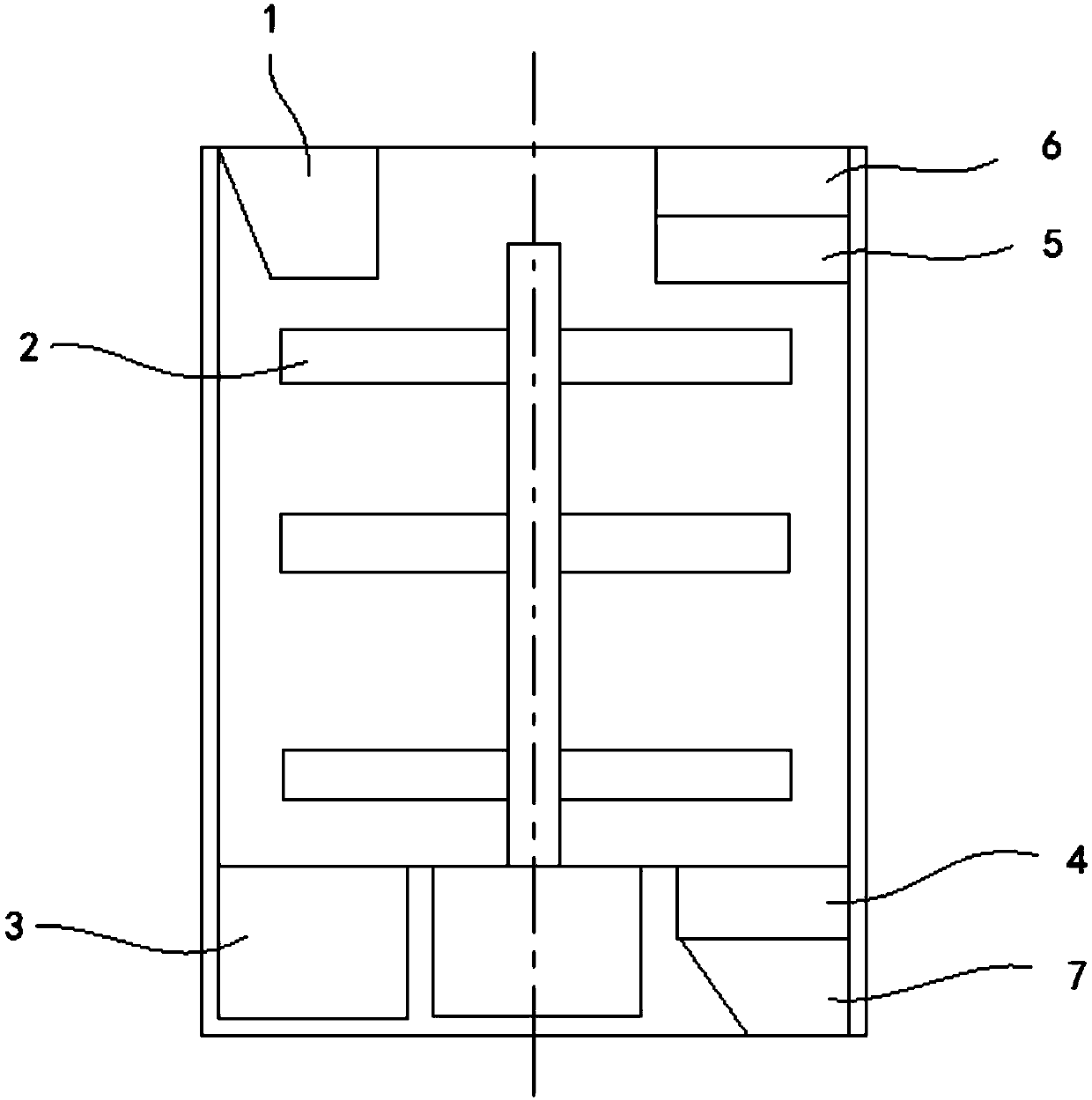

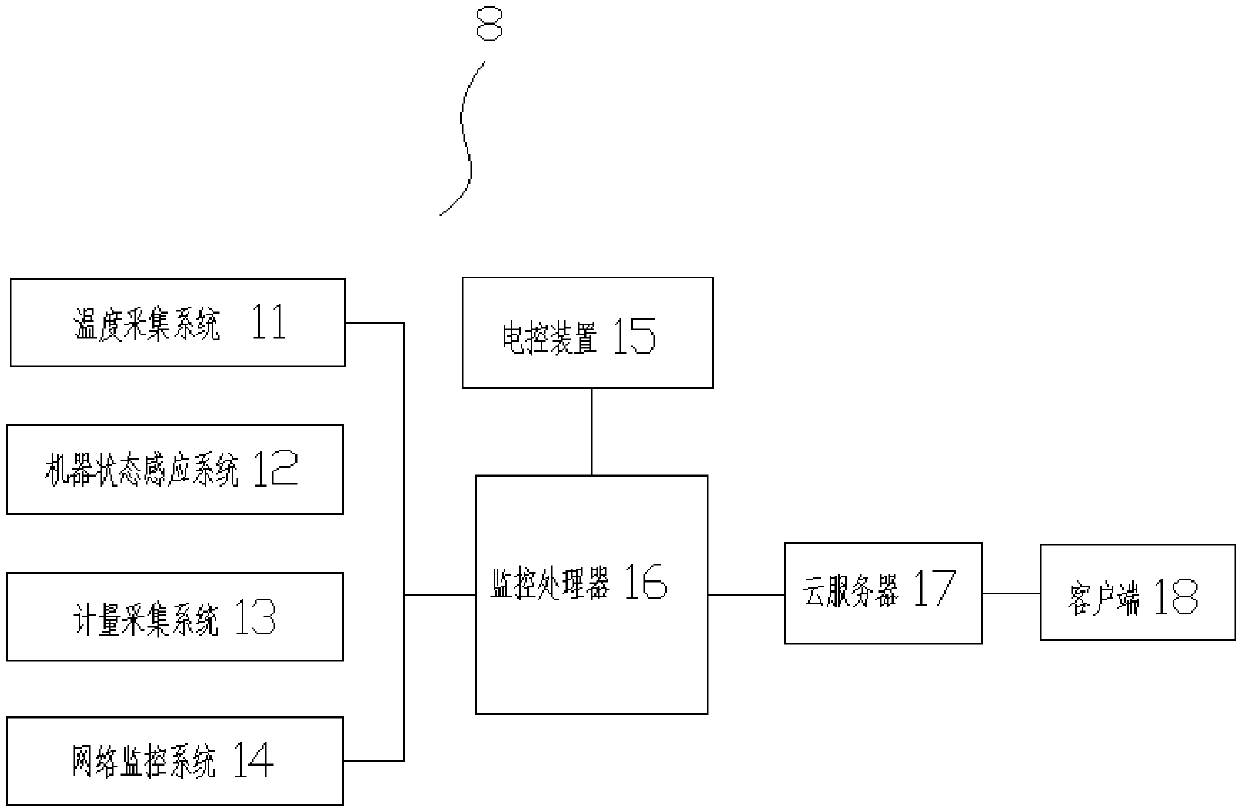

[0040] The present invention will be described in detail below in conjunction with accompanying drawings and embodiments, but those skilled in the art should know that the following embodiments are not the only limitation to the technical solution of the present invention, and any work done under the spirit of the technical solution of the present invention Equivalent transformation or modification shall be considered as belonging to the protection scope of the present invention.

[0041] The novel waste biogrease treatment process route provided by the invention is as follows:

[0042] On-site collection---pre-treatment (crushing-solid-liquid separation-oil-water preliminary separation)---into the integrated integrated reactor for one-time treatment---generation of detergent---on-site reuse or sale. Some, such as waste oil from range hoods, frying oil, etc. do not require pretreatment, and can be directly fed into the integrated integrated reactor to produce detergent for use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com