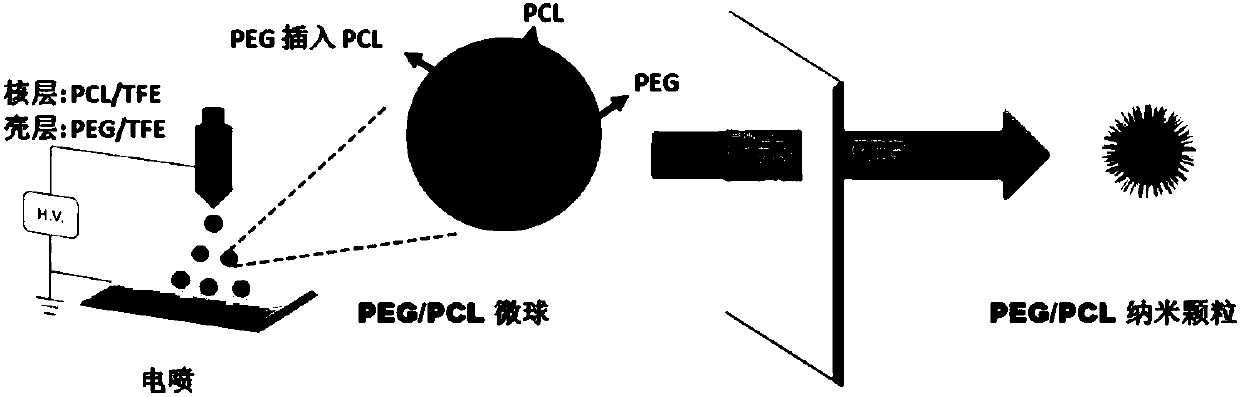

Method for preparing core-shell structure nanoparticles on basis of coaxial electrostatic spraying shell insertion strategy

A technology of coaxial electrospray and core-shell structure, applied in the field of nanomaterial preparation, can solve problems such as unstable core-shell structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

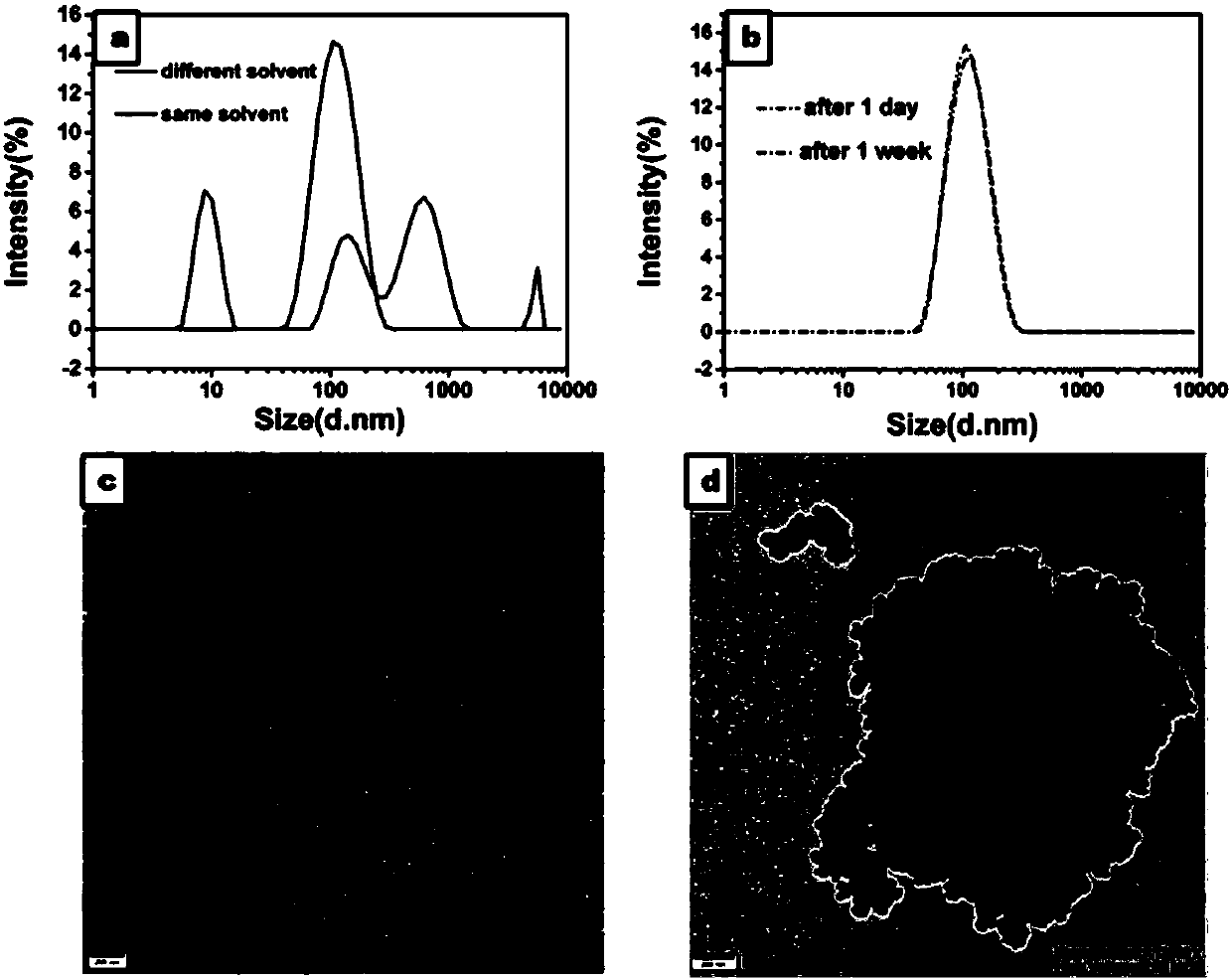

[0020] A certain amount of hydrophilic polymer PEG (Mn=20000) was weighed, dissolved in the solvent TFE (trifluoroethanol), and a solution with a concentration of 10% was prepared as the shell solution. Weigh a certain amount of hydrophobic polymer PCL (Mn=10000), dissolve it in the solvent TFE (trifluoroethanol), and configure a PCL / TFE solution with a concentration of 6% as the core layer solution; prepare the core shell by coaxial electrospray Structural microspheres. Set the distance between the nozzle and the receiving plate to be 20 cm, and inject the PEG and PCL solutions into the nozzle through two independent syringe pumps. The injection rate of the shell layer was 1.2mL / h, and that of the core layer was 0.3mL / h. Adjust the high-voltage power supply voltage to about 20kV, and at this time, a stable Taylor cone is formed at the bottom of the nozzle. Collect the EFI particles onto tinfoil. The morphology and particle size were characterized by SEM. Take a certain am...

Embodiment 2

[0022] The same method as in Example 1 was used to prepare core-shell microspheres. The shell solution is PEG / TFE, the core solution is PCL / TFE, the injection speed of the fixed shell PEG solution is 1.2mL / h, and the injection speed of the core layer PCL solution is 0.5mL / h, 0.4mL / h , 0.3mL / h, other parameters are all the same as in Example 1. Three groups of core-shell microspheres were prepared by coaxial electrospraying. Take a certain amount of core-shell microspheres prepared by the above method, dissolve them in deionized water, filter, and measure their hydrated particle sizes by DLS.

Embodiment 3

[0024] Weigh a certain amount of hydrophilic polymer PEG (Mn=20000), dissolve it in the solvent TFE (trifluoroethanol), and configure a solution with a concentration of 10% as the shell solution; weigh a certain amount of hydrophobic polymer PLA (Mn=17000) was dissolved in the solvent TFE (trifluoroethanol), and a PLA / TFE solution with a concentration of 6% was prepared as a core layer solution; core-shell microspheres were prepared by coaxial electrospraying. Set the distance between the nozzle and the receiving plate to be 20 cm, and inject the PEG and PCL solutions into the nozzle through two independent syringe pumps. The injection rate of the shell layer was 1.2mL / h, and that of the core layer was 0.3mL / h. Adjust the high-voltage power supply voltage to about 20kV, and at this time, a stable Taylor cone is formed at the bottom of the nozzle. Collect the EFI particles onto tinfoil. The morphology and particle size were characterized by SEM. Take a certain amount of elec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Hydrated particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com