Impact hardening material and preparation method thereof

A technology of catalyst and boron compound, which is applied in the field of impact hardening materials and its preparation, can solve the problems of poor formability and low material strength, and achieve the effects of improving elastic modulus and dimensional stability, excellent mechanical properties, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0063] The invention provides a method for preparing an impact hardening material, comprising:

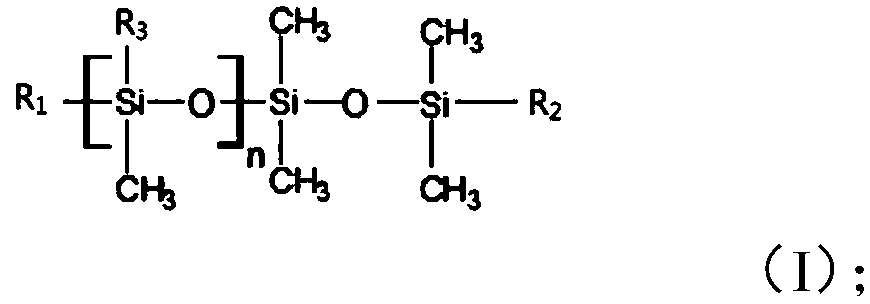

[0064] A) The main chain oligomer having the structure shown in formula (I), the chain extender and the boron-containing compound are mixed and reacted to obtain an initial reaction system;

[0065]

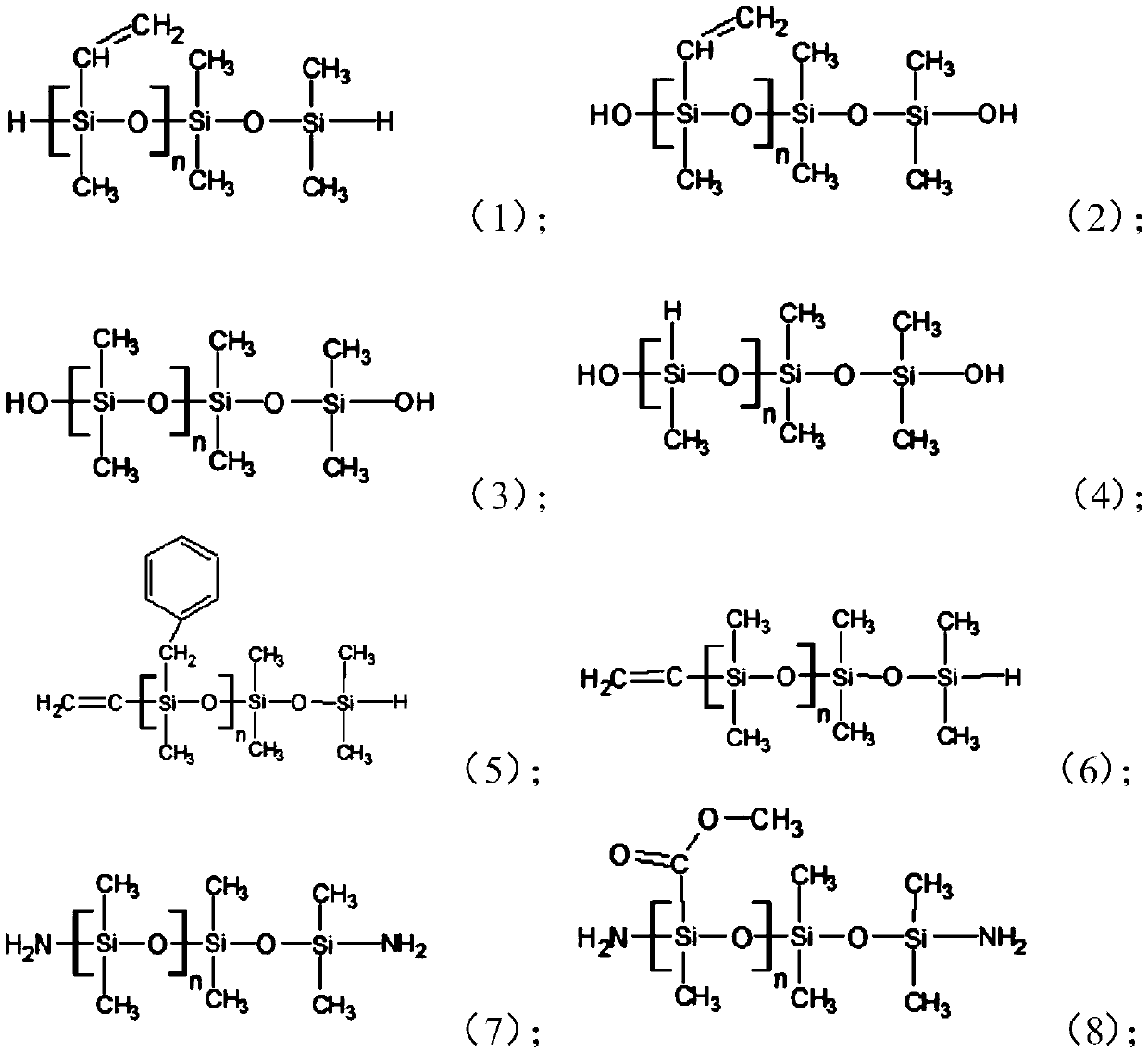

[0066] Among them, R 1 and R 2 independently selected from -H, hydroxyl, vinyl or amino;

[0067] R 3 selected from -H, alkyl, vinyl, ester or benzyl;

[0068] n is 40-2800;

[0069] B) mixing the initial reaction system, a branched oligomer having a structure represented by formula (II), a chemical crosslinking agent and a catalyst, and reacting to obtain an impact hardening material;

[0070]

[0071] Among them, R 4 selected from -H, hydroxyl or vinyl;

[0072] R 5 is an alkyl group;

[0073] R 6 selected from alkyl or benzyl;

[0074] n is 3-280;

[0075] The catalyst is selected from one of (1,5-cyclooctadiene) platinum dichloride, sodium tetrachloroaurate and b...

Embodiment 1

[0145] Mix 15 g of the main chain oligomer (n=170) having the structure shown in formula (2) and 0.75 g of toluene diisocyanate, and react for 4 hours at 150° C. and a stirring speed of 400 rad / s; then, add four 1.25g of hydroxydiborane was continued to react at 150°C for 4h to obtain the initial reaction system.

[0146] The initial reaction system was mixed with 5 g of branched oligomers (n=50) having a structure represented by formula (9), and reacted for 2 hours at 70° C. and a stirring speed of 400 rad / s; then, adding 3g of the chemical crosslinking agent (n=10) and 0.01g of (1,5-cyclooctadiene)platinum dichloride were reacted at 70°C for 12h to obtain an impact hardened material.

Embodiment 2

[0148] Mix 12 g of the main chain oligomer (n=2000) having a structure represented by formula (4) and 0.65 g of 4,4-dicyclohexylmethane diisocyanate, and mix them at 130°C and a stirring speed of 300 rad / s. React for 3 hours; then, add 1.35 g of p-hydroxyphenylboronic acid and continue to react for 3 hours at 130° C. to obtain an initial reaction system.

[0149] The initial reaction system was mixed with 5 g of branched oligomers (n=150) having the structure shown in formula (12), and reacted for 2 hours at 80° C. with a stirring speed of 300 rad / s; then, adding 3g of chemical crosslinking agent (n=25) and 0.02g of bicyclooctene rhodium chloride dimer were reacted at 80°C for 16h to obtain an impact hardening material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com