Preparation method and application of degradable mulching film coating

A degradable mulch and coating technology, which is applied in the field of preparation of degradable mulch coatings, can solve the problems of low durability, poor toughness of straw-based films, and poor gas barrier properties, so as to improve anti-aging performance, gas barrier properties, The effect of slowing down erosion and degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation steps of this embodiment are as follows;

[0035] 1. Add 16 g of chitosan and 200 g of 1% acetic acid into a three-necked flask, stir for 1 h at 320 rpm, and stir for 1 h to obtain a chitosan solution;

[0036] 2. Take 100 g of the above-mentioned chitosan solution and place it on a magnetic stirrer, add 3 g of nanocellulose and 1 g of glycerin and stir for 60 min at 45°C to obtain a mixed solution of nanocellulose / chitosan; prepare it into a degradable Mulch coating solution-1.

Embodiment 2

[0038] The preparation steps of this embodiment are as follows;

[0039]1. Add 16 g of chitosan and 200 g of 1% acetic acid into a three-necked flask, stir at 320 rpm for 1 h to obtain a chitosan solution;

[0040] 2. Take 100 g of the above-mentioned chitosan solution and place it on a magnetic stirrer, add 3 g of nanocellulose and 1 g of glycerin and stir at 45°C for 60 min to obtain a mixed solution of nanocellulose / chitosan for later use;

[0041] 3. Mix 10 g of carboxylated styrene-butadiene latex into 100 g of nanocellulose / chitosan mixed solution, adjust the pH to 7.5~8.0 with sodium hydroxide, and prepare degradable mulch coating solution-2.

Embodiment 3

[0043] The preparation steps of this embodiment are as follows;

[0044] 1. Add 16 g of chitosan and 200 g of 1% acetic acid into a three-necked flask, stir at 320 rpm for 1 h, then add 0.2 g of sodium laurate and 4 g of nano-TiO 2 Mix well and stir for 1 h to get nano-TiO 2 / chitosan solution;

[0045] 2. Take the above nano-TiO 2 100 g of chitosan / chitosan solution was placed on a magnetic stirrer, 3 g of nanocellulose and 1 g of glycerol were added and stirred at 45 °C for 60 min to obtain nanocellulose / TiO 2 / chitosan mixed solution;

[0046] 3. Mix 10 g carboxylated styrene-butadiene latex into 100 g nanocellulose / TiO 2 In the mixed solution of chitosan, use an emulsifier to disperse the above solution at 1500r for 15 minutes. The solution is in the form of a uniform emulsion. Use sodium hydroxide to adjust the pH to 7.5~8.0 to obtain degradable film coating solution-3.

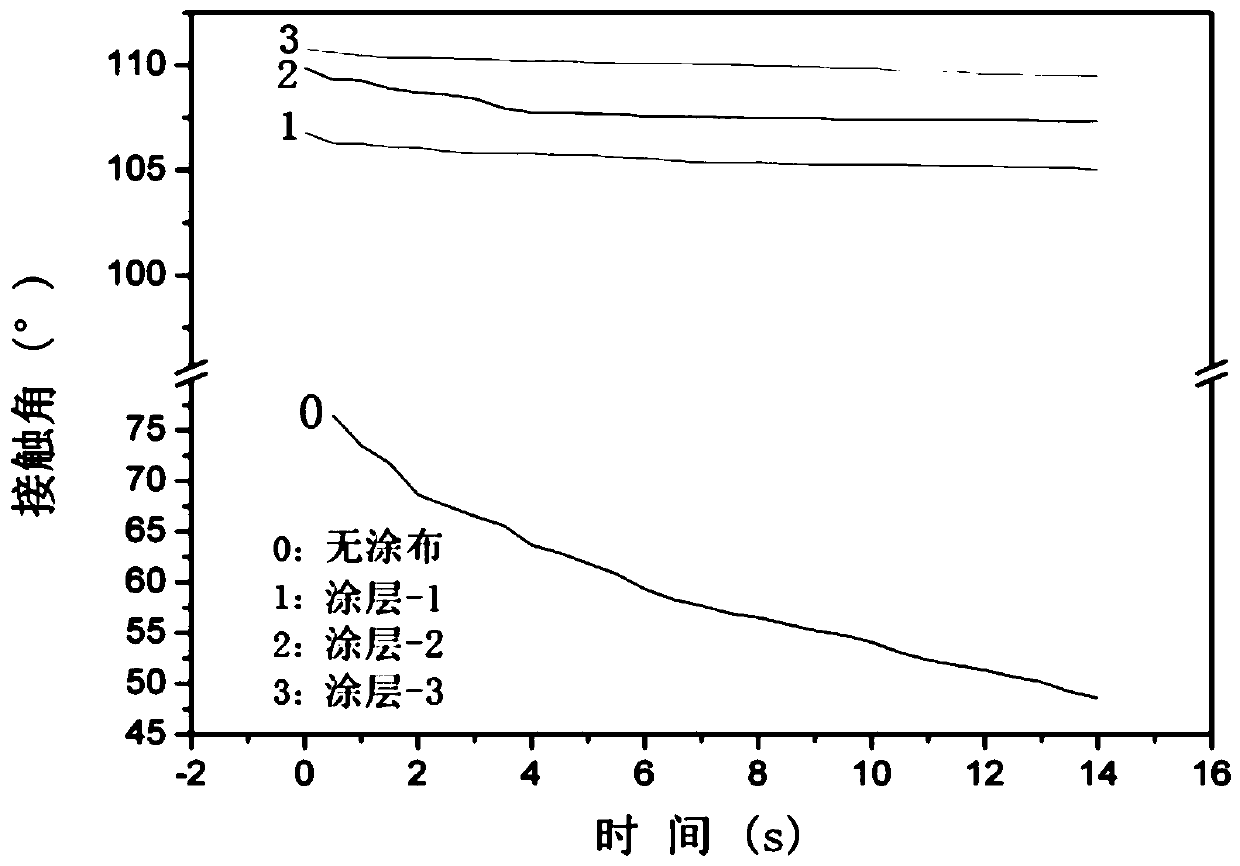

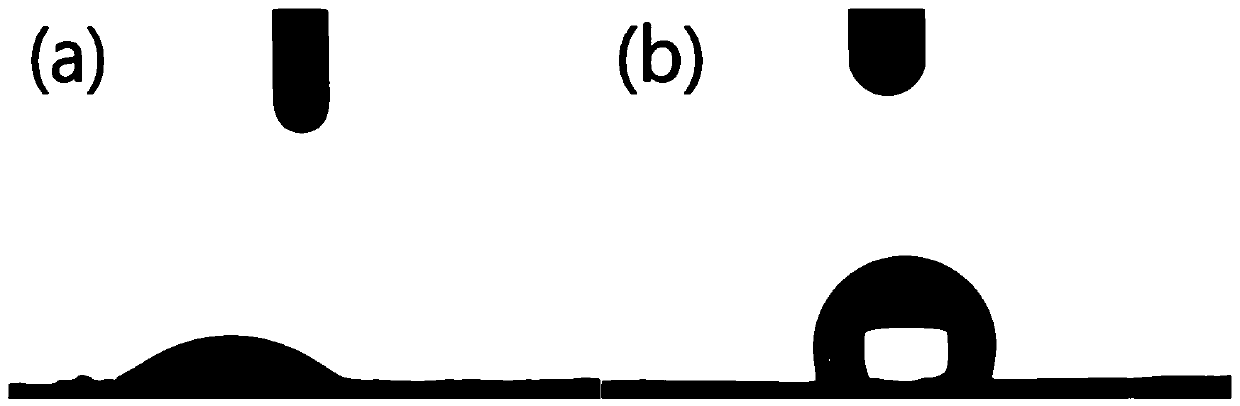

[0047] The degradable plastic film coating solution-1, the degradable plastic film coating sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| tear load | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com