Silk-screen printing ink and preparation method thereof

A technology for screen printing ink and ink, applied in the field of screen printing ink and its preparation, can solve the problems of difficult mirror effect ink, lack of printability, easy erosion of substrates, etc. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

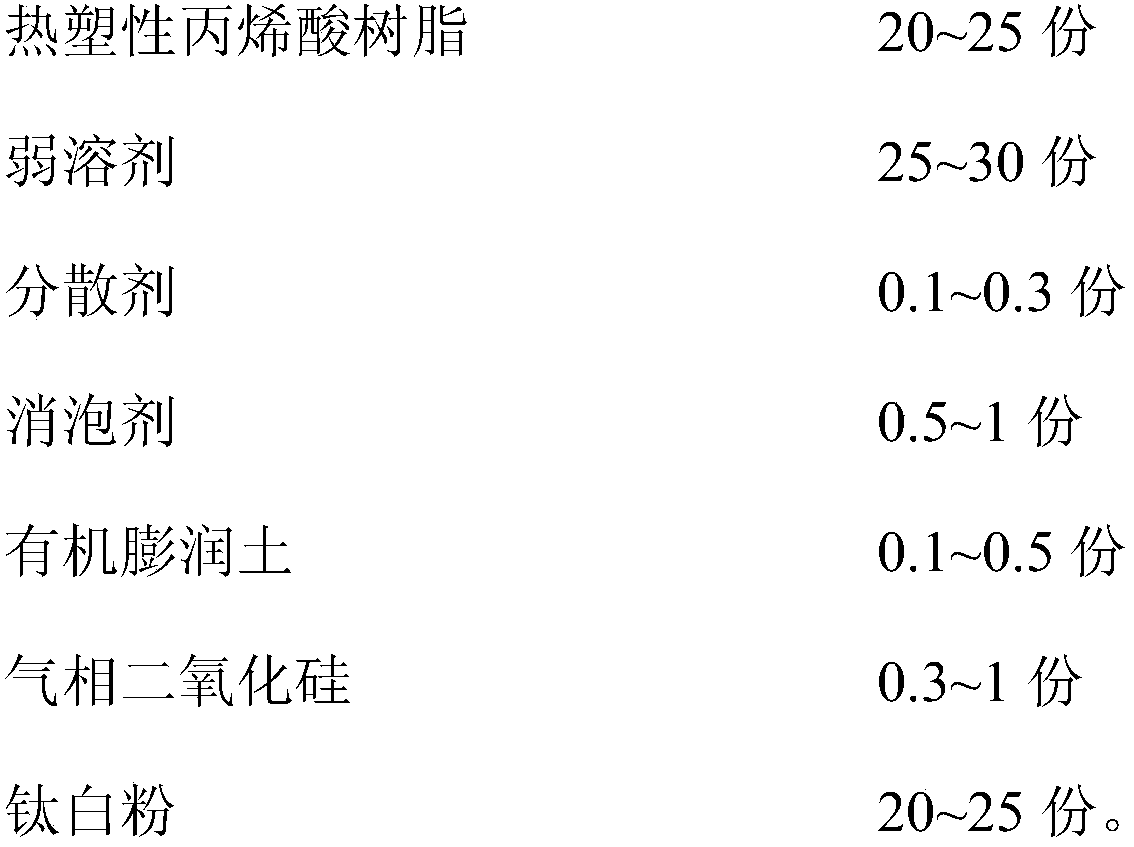

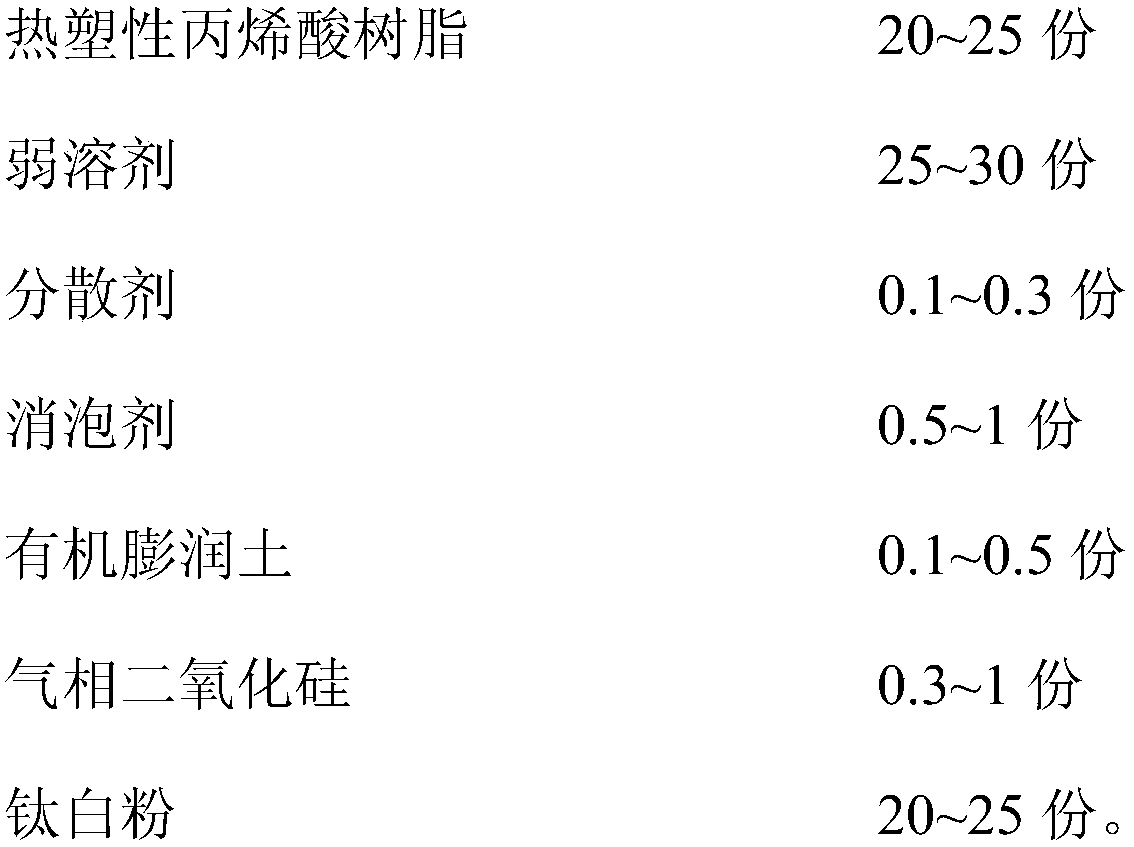

[0049] The preparation method of screen printing ink of the present invention, described preparation method comprises the steps:

[0050] 1) In parts by weight, add 25 to 30 parts of weak solvent into the stirring tank, add 20 to 25 parts of thermoplastic acrylic resin while stirring, stir until completely dissolved, and form a viscous and transparent resin liquid after cooling;

[0051] 2) Put the viscous transparent resin liquid obtained in step 1) in a stirring tank and stir, and add 0.1 to 0.3 parts of dispersant, 0.1 to 0.5 parts of organic bentonite, 0.3 to 1 part of fumed silica, 20-25 parts of titanium dioxide, stirred until evenly mixed, and then ground to obtain a transparent viscous ink intermediate;

[0052] 3) The transparent viscous ink intermediate obtained in step 2) is placed in a stirring tank and stirred, and 0.5 to 1 part of defoamer is added while stirring in parts by weight, and the screen printing ink is obtained after stirring evenly.

Embodiment 1

[0054] The preparation method of the screen printing ink of the present embodiment, comprises the steps:

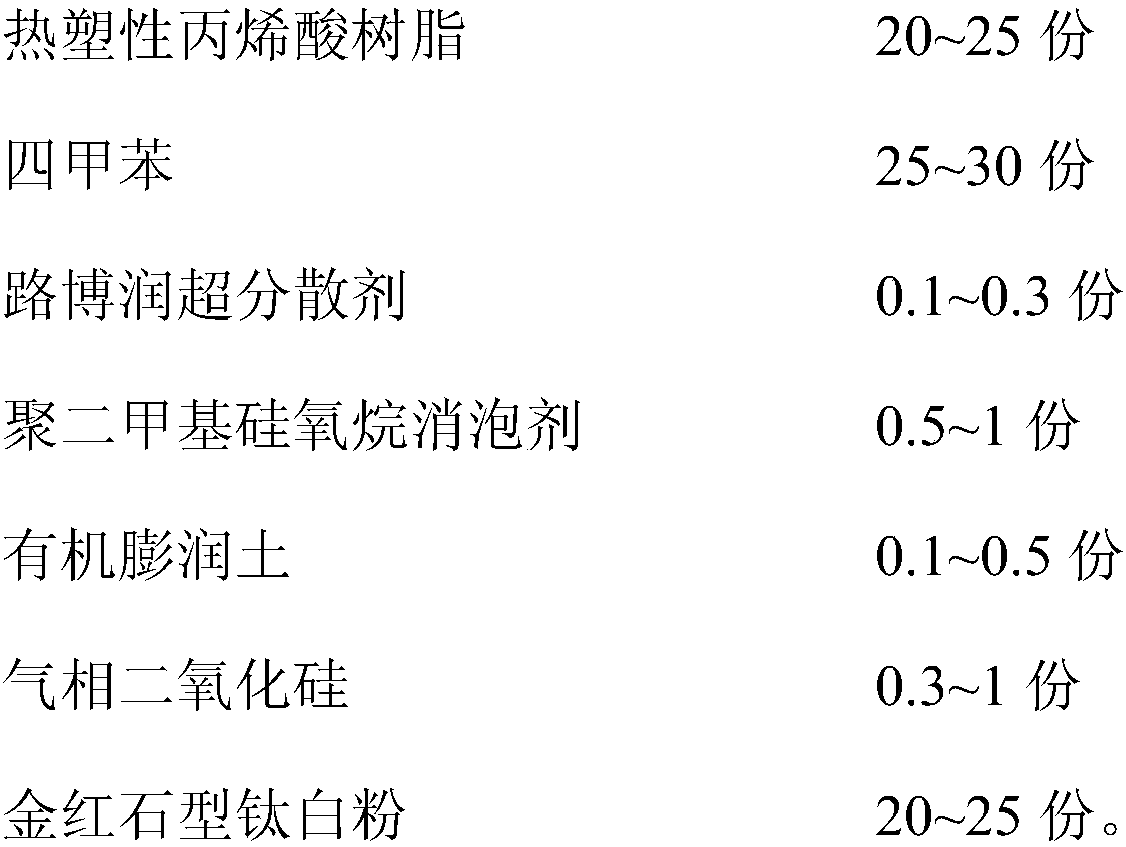

[0055] 1) Under normal temperature and pressure, add 25 parts of tetramethylbenzene into the stirring tank by weight, add 25 parts of thermoplastic acrylic resin while stirring, stir at a stirring speed of 800r / min for 2 hours until it is completely dissolved, and form a viscous mixture after cooling. Thick transparent resin liquid;

[0056] 2) Under normal temperature and pressure, put the viscous transparent resin liquid obtained in step 1) into a stirring tank and stir, and in parts by weight, add 0.1 part of Lubrizol hyperdispersant, 0.5 part of Organic bentonite, 0.5 parts of fumed silica, 20 parts of rutile titanium dioxide, stirred at a stirring speed of 600r / min for 20 minutes until uniformly mixed, and then ground by a three-roller machine to obtain a transparent viscous ink intermediate;

[0057] 3) Under normal temperature and pressure, place the transparent v...

Embodiment 2

[0059] The preparation method of the screen printing ink of the present embodiment, comprises the steps:

[0060] 1) Under normal temperature and pressure, add 28 parts of tetramethylbenzene into the stirring tank in parts by weight, add 22 parts of thermoplastic acrylic resin while stirring, stir at a stirring speed of 900r / min for 1.6h until it is completely dissolved, and form after cooling Viscous transparent resin liquid;

[0061] 2) Under normal temperature and pressure, put the viscous transparent resin liquid obtained in step 1) into a stirring tank and stir, and in parts by weight, add 0.2 parts of Lubrizol hyperdispersant, 0.4 parts of Organic bentonite, 0.7 parts of fumed silica, 22 parts of rutile titanium dioxide, stirred at a stirring speed of 700r / min for 16 minutes until uniformly mixed, and then ground by a three-roller machine to obtain a transparent viscous ink intermediate;

[0062] 3) Under normal temperature and pressure, place the transparent viscous in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com