Production method of super high breaking strength chinlon 66 industrial yarn

A technology of breaking strength and production method, applied in the production field of ultra-high breaking strength nylon 66 industrial yarn, can solve problems such as failure to reach breaking strength, and achieve the effects of reducing impurity content, less wool and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The production method of ultra-high breaking strength nylon 66 industrial yarn of the present invention, the detailed steps of this production method are as follows:

[0053] a. Solid-phase polymerization thickening: first, put the nylon 66 slices with a relative viscosity of 2.28 into the reaction container, and dry the nylon 66 slices with nitrogen at 160°C. The drying time is 15 hours. slice;

[0054] b. Slice melt extrusion: send the high-viscosity slice obtained in step a to a screw extruder, adjust the temperature of the screw extruder to 310° C., and melt the high-viscosity slice to obtain a melt;

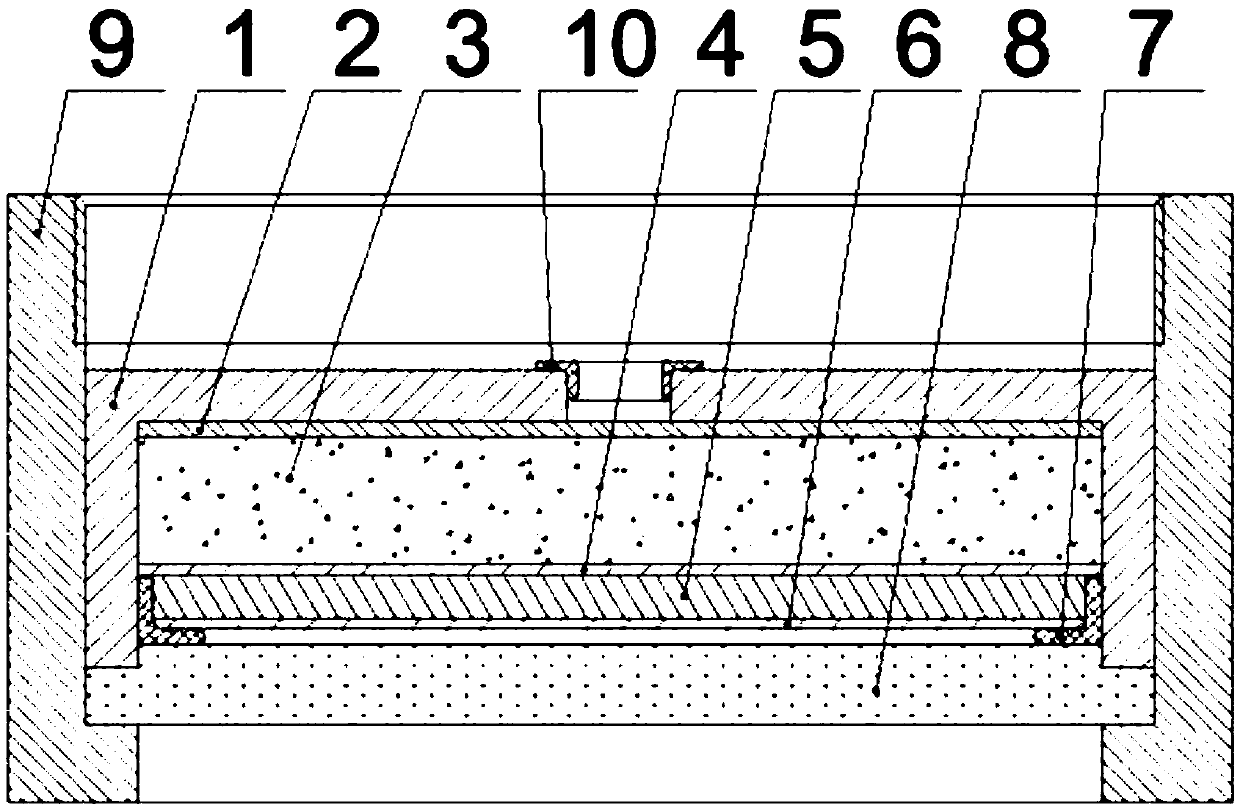

[0055] c. Melt filtration metering and spinning: The melt obtained in step b is sent to the spinning box assembly through the melt pipeline. After the melt enters the spinning box assembly, it first passes through the filter screen and the first metal fiber provided in the assembly. The felt and the second metal fiber felt are filtered, and after filtration, they are...

Embodiment 2

[0069] Embodiment 2: basically the same as Embodiment 1, the difference is:

[0070] The production method of ultra-high breaking strength nylon 66 industrial yarn of the present invention, the detailed steps of this production method are as follows:

[0071] a. Solid-phase polymerization thickening: First, put nylon 66 slices with a relative viscosity of 2.32 into the reaction container, and dry the nylon 66 slices with nitrogen at 150°C for 20 hours. After drying, a high-viscosity nylon 66 slice with a relative viscosity of 2.82 is obtained slice;

[0072] b. Slice melt extrusion: Send the high-viscosity slices obtained in step a to a screw extruder, adjust the temperature of the screw extruder to 300°C to melt the high-viscosity slices to obtain a melt;

[0073] c. Melt filtration metering and spinning: The melt obtained in step b is sent to the spinning box assembly through the melt pipeline. After the melt enters the spinning box assembly, it first passes through the fil...

Embodiment 3

[0084] Embodiment 3: basically the same as Embodiment 1, the difference is:

[0085] The production method of ultra-high breaking strength nylon 66 industrial yarn of the present invention, the detailed steps of this production method are as follows:

[0086] a. Solid-phase polymerization thickening: First, put the nylon 66 slices with a relative viscosity of 2.40 into the reaction container, and dry the nylon 66 slices with nitrogen at 140°C for 23 hours. After drying, a high-viscosity nylon 66 slice with a relative viscosity of 2.80 slice;

[0087] b. Slice melt extrusion: send the high-viscosity slice obtained in step a to a screw extruder, adjust the temperature of the screw extruder to 315° C. to melt the high-viscosity slice to obtain a melt;

[0088] c. Melt filtration metering and spinning: The melt obtained in step b is sent to the spinning box assembly through the melt pipeline. After the melt enters the spinning box assembly, it first passes through the filter scre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com