Changeable type extending-retracting transverse-movement reinforcing steel bar trolley

A steel trolley and lateral movement technology, which is applied in the direction of hydroelectric power station, shaft lining, tunnel lining, etc., can solve the problems that affect the construction progress, cannot realize the independent transfer of the trolley, recycle, increase the construction cost, etc., and achieve project saving The effect of reducing construction cost, improving the utilization rate of the trolley, and increasing the construction height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

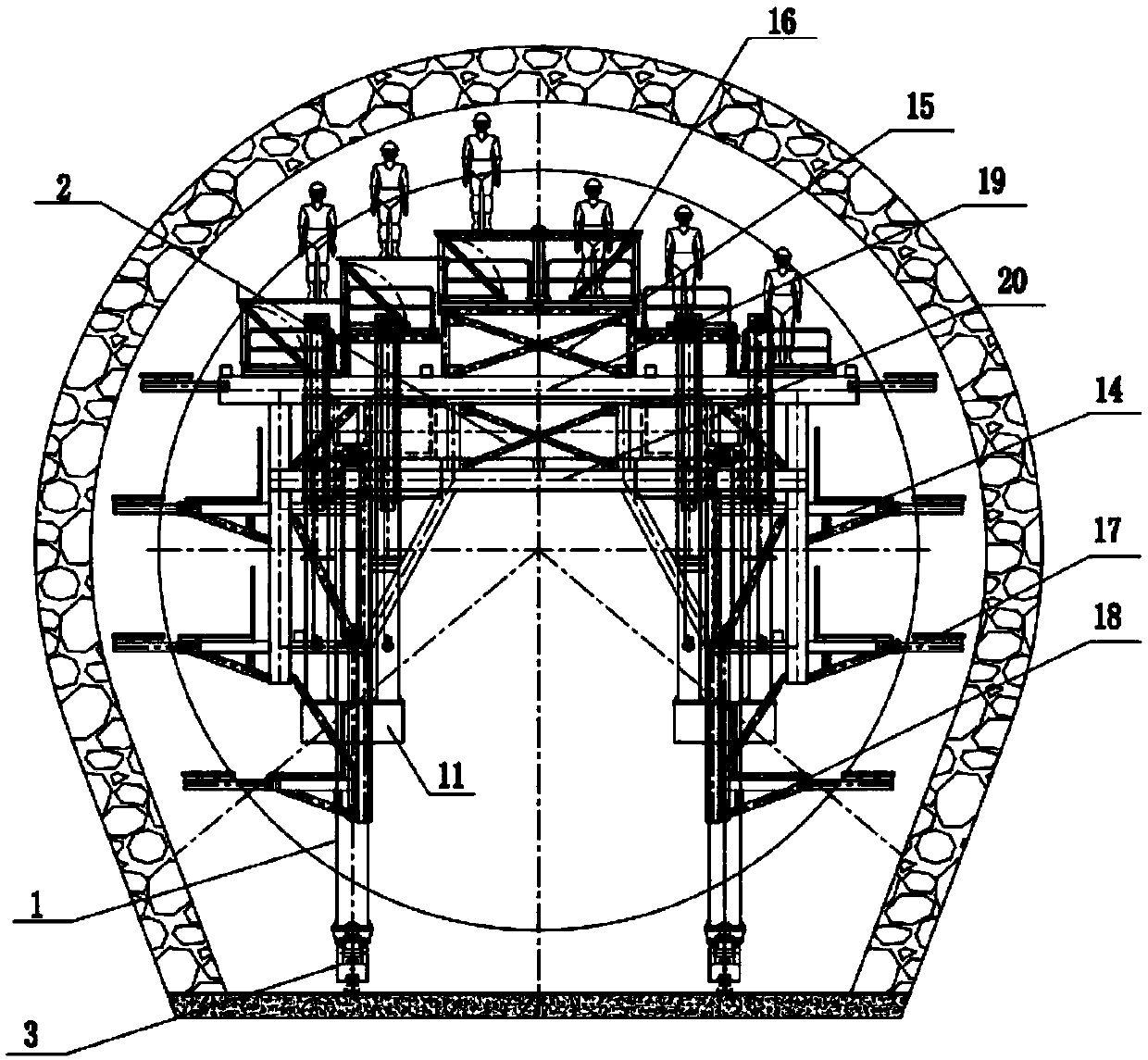

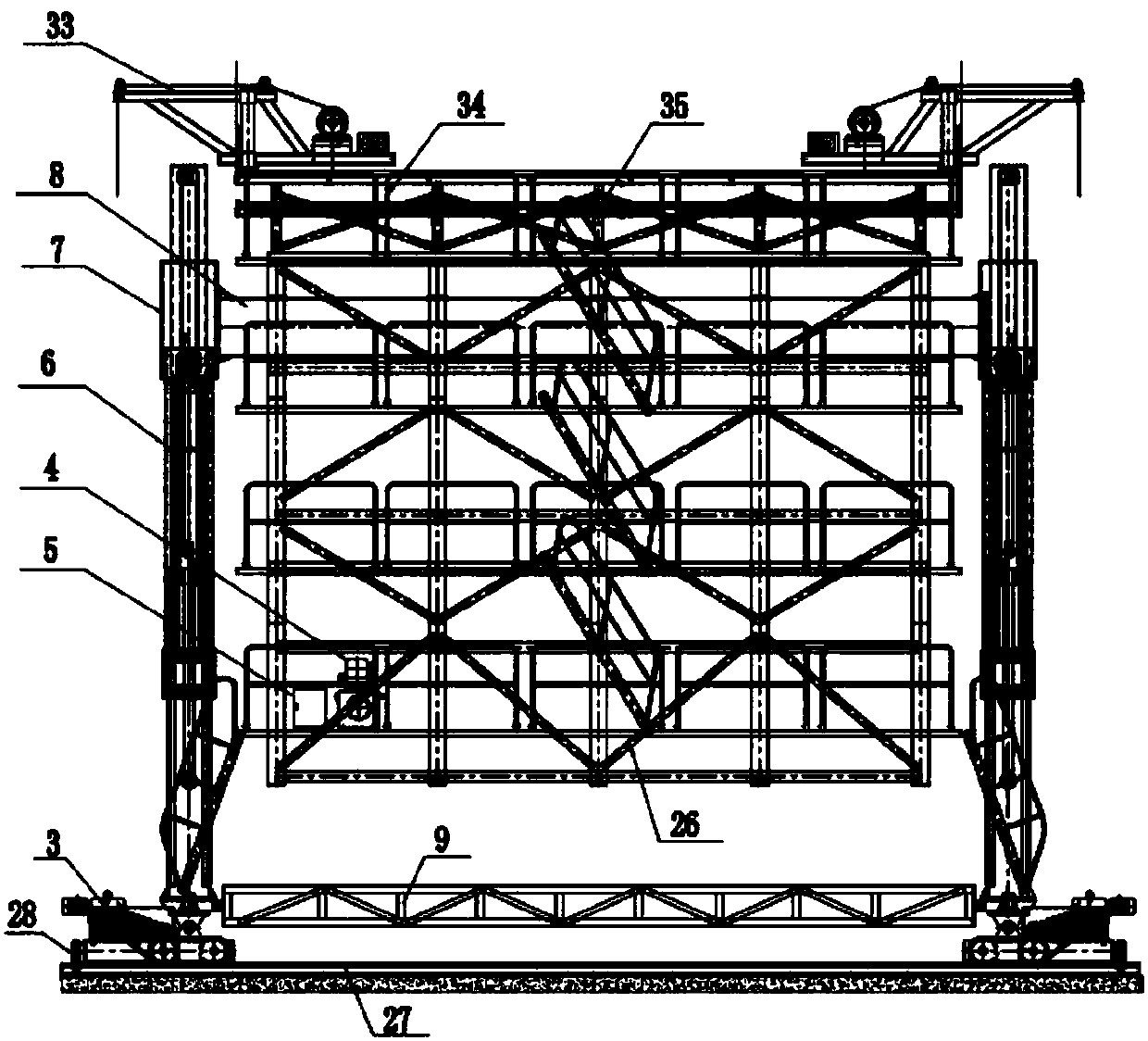

[0034] see Figure 1-11 : A variable telescopic and laterally moving steel bar trolley, comprising a supporting mast 1 and a bracket 2 arranged on the top of the supporting mast 1 .

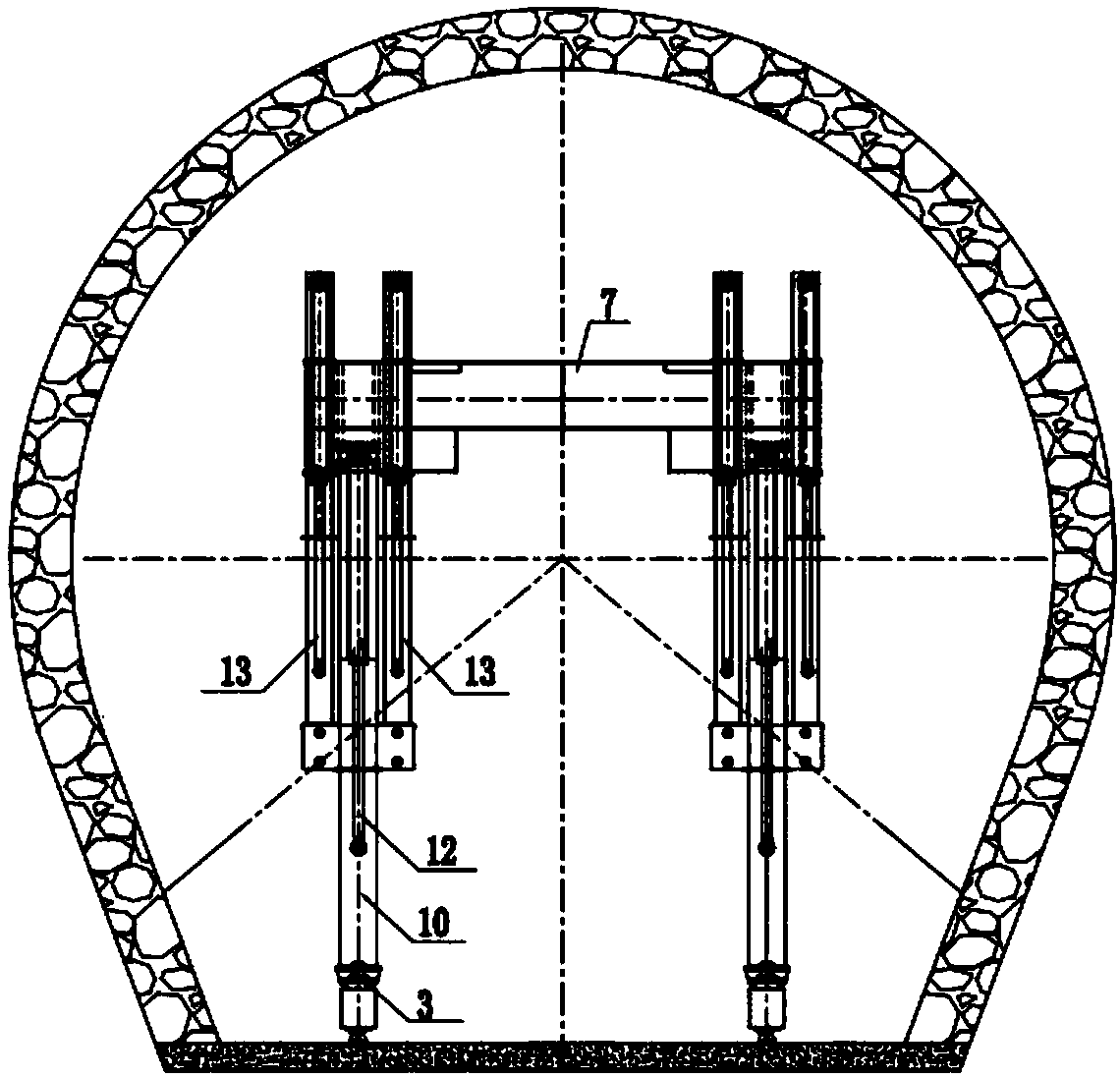

[0035] The support portal frame 1 includes a vertical support structure 6 , a lateral support beam 7 , a longitudinal support beam 8 , and a walking connecting beam 9 , and the vertical support structure 6 includes a column 10 and a jacking system 11 .

[0036] The bracket 2 is a three-dimensional frame structure of a multi-layer platform, including a platform support system, a top platform 15 arranged on the top of the platform support system, and side telescopic platforms 14 hinged on both sides of the platform support system. The top platform 15 consists of multiple Layer can prop up the overturn frame 16 and the steel cover plate to form, and the walking link 9 two ends are equipped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com