Wood-imitating skirting board capable of heating and manufacturing method thereof

A technology of skirting and imitation wood, applied in the field of imitation wood skirting and its production, can solve the problem of large area for rectification, and achieve the effects of easy installation and replacement, good heating and decorative effects, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

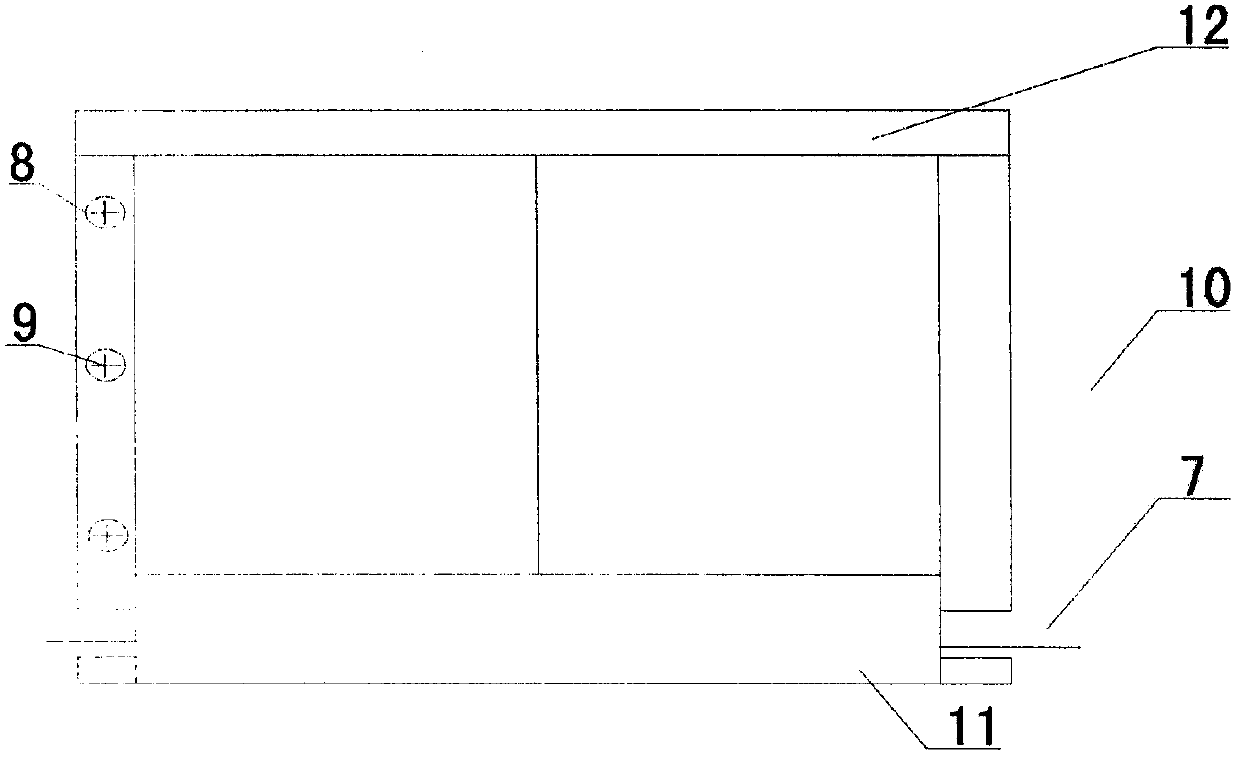

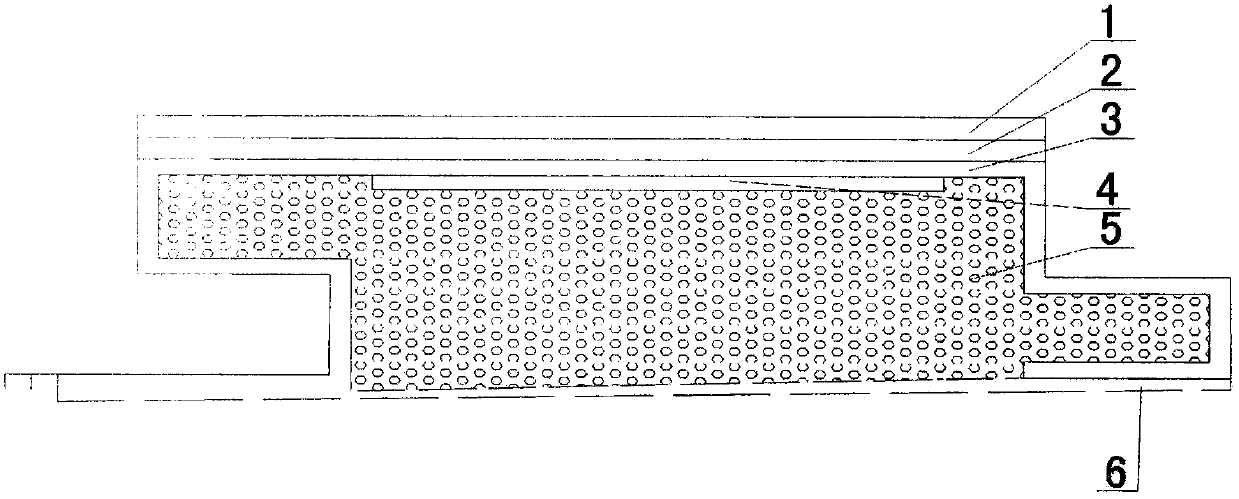

[0016] Wood-like dado panel of the present invention comprises six layers of structure (see image 3 shown), from outside to inside are wear-resistant layer 1, decorative layer 2, skeleton layer 3, heat generating layer 4, heat preservation layer 5, and reflective layer 6; the manufacturing steps are as follows: first, in the One side of the aluminum-magnesium alloy plate with a thickness of 0.5mm is pasted with a composite decorative layer 2, that is, a PVC film, and wood grain patterns or stone patterns and other colors are drawn on the film for decoration and beautification: then hot-press trioxide on the decorative layer 2 Two aluminum films are used as the wear-resistant layer 1, which is the first layer of the imitation wood dado panel and is the outermost layer. Then, the half-finished wall skirting board composed of the skeleton layer 3 and the composite upper decorative layer 2 and hot-pressed upper wear-resistant layer 1 is then molded with special equipment accordin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com