Steel structural intercooling tower with smoke discharging function

A steel structure and cooling tower technology, applied in towers, building components, building structures, etc., can solve the problems of large investment costs, complex smoke exhaust and cooling systems, etc., and achieve good earthquake resistance, outstanding economic and environmental advantages, and environmental protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

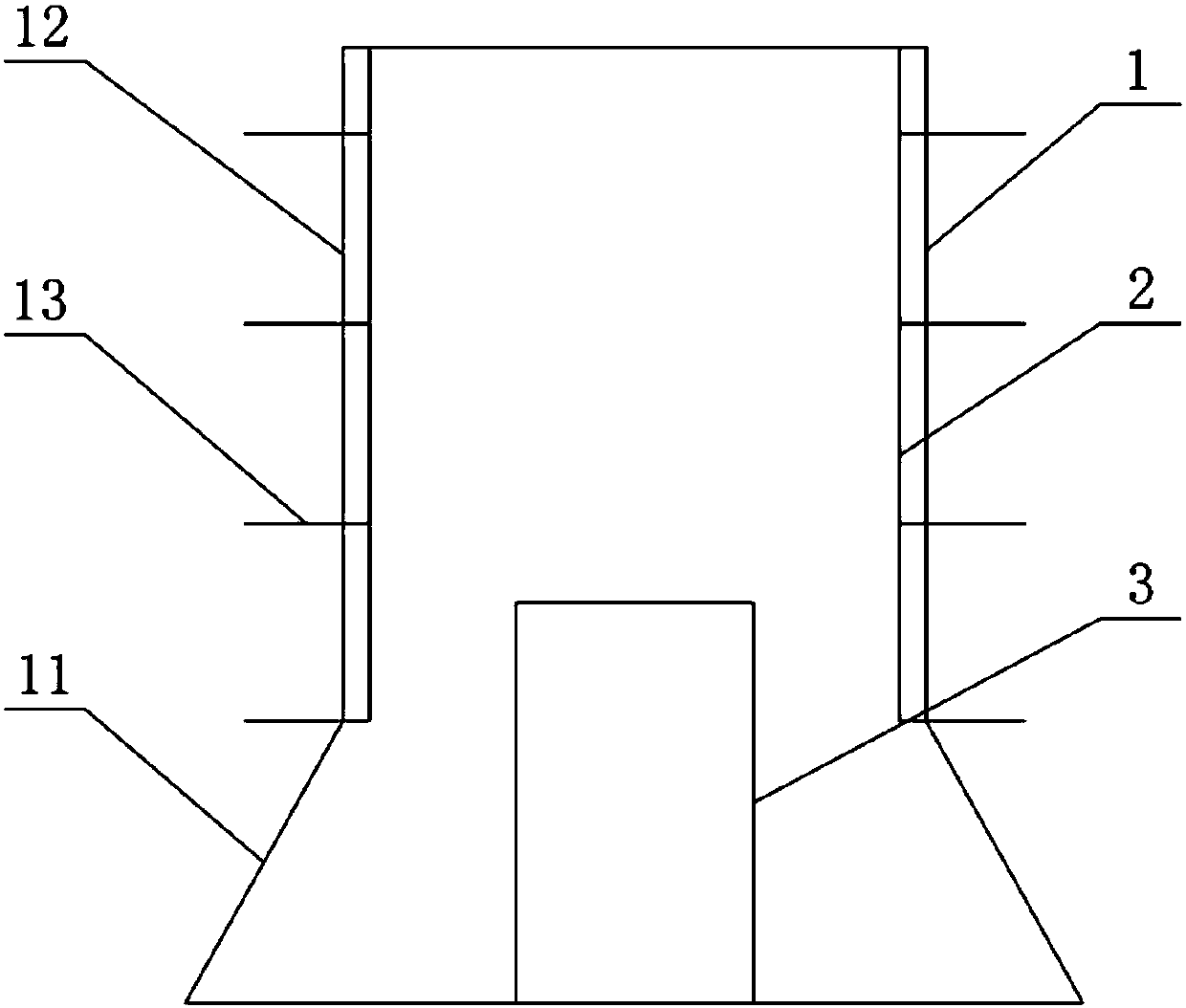

[0019] Such as figure 1 Shown, the present invention is a kind of intercooling tower of steel structure with smoke exhaust function, and its structure mainly comprises steel structure tower body 1 and is positioned at the built-in skin 2 of steel structure tower body 1 inside, and the interior of built-in skin 2 is provided with Chimney 3; the height of the built-in skin 2 is the same as that of the steel structure tower body 1, and the height of the chimney 3 is lower than half of the height of the steel structure tower body 1.

[0020] The built-in skin is spliced aluminum panels with a thickness of 2mm. Both the inner surface and the outer surface of the built-in skin 2 are provided with anti-corrosion coatings. The built-in skin 2 includes a top skin located in the upper one-third area and a bottom skin located in the lower two-thirds area, and the thickness of the anti-corrosion coating on the top skin is greater than 1.5 times the thickness of the anti-corrosion coati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com