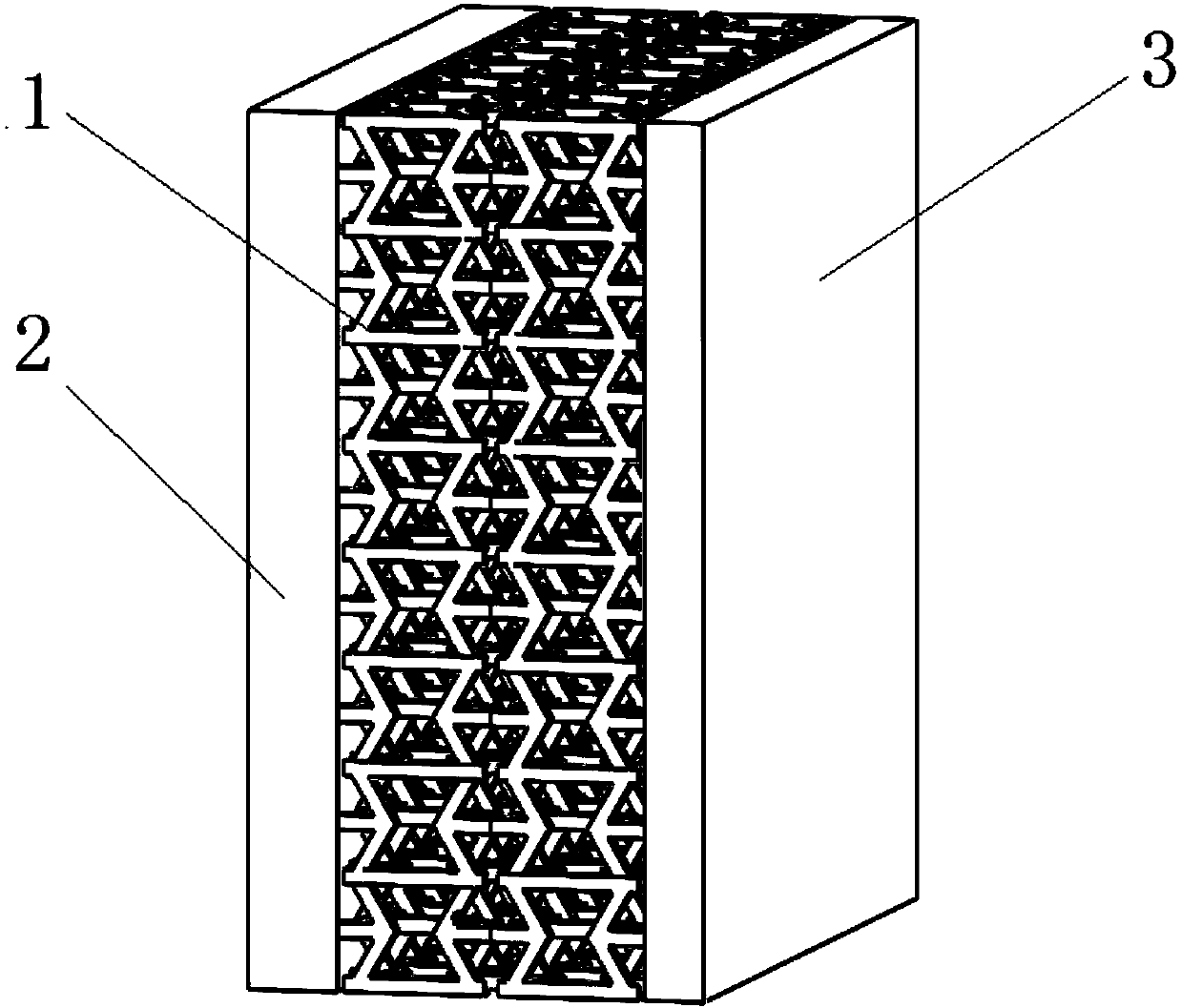

Composite sandwich bulletproof structure

A technology of sandwich and core layer, applied in the direction of the structure of the armor plate, can solve the problems of poor penetration resistance and low strength, and achieve good energy absorption and shock absorption performance, high impact strength, and high fracture resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

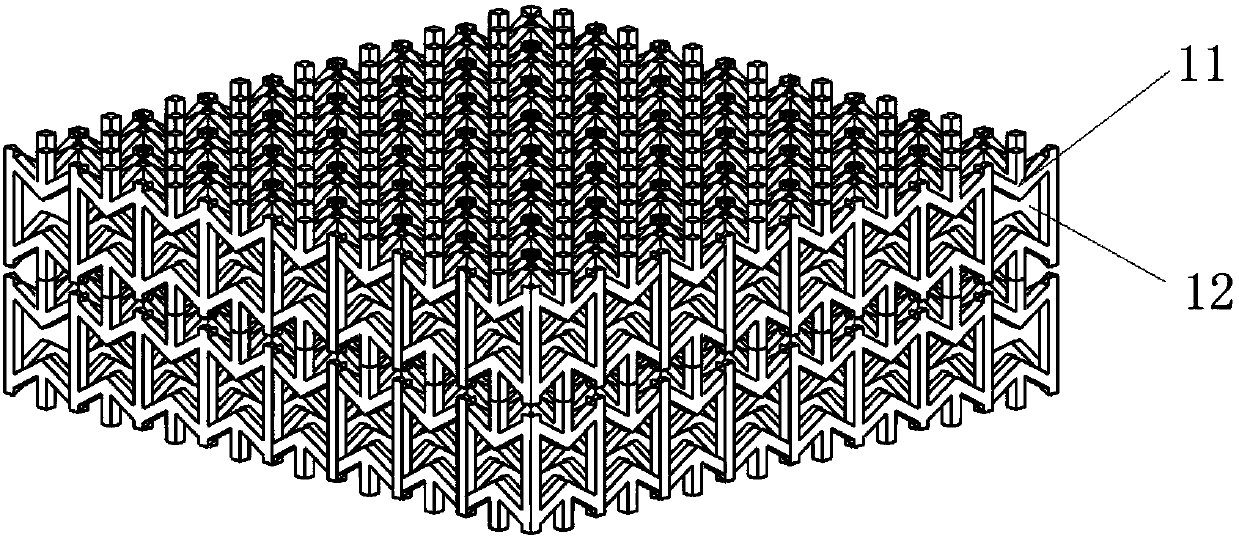

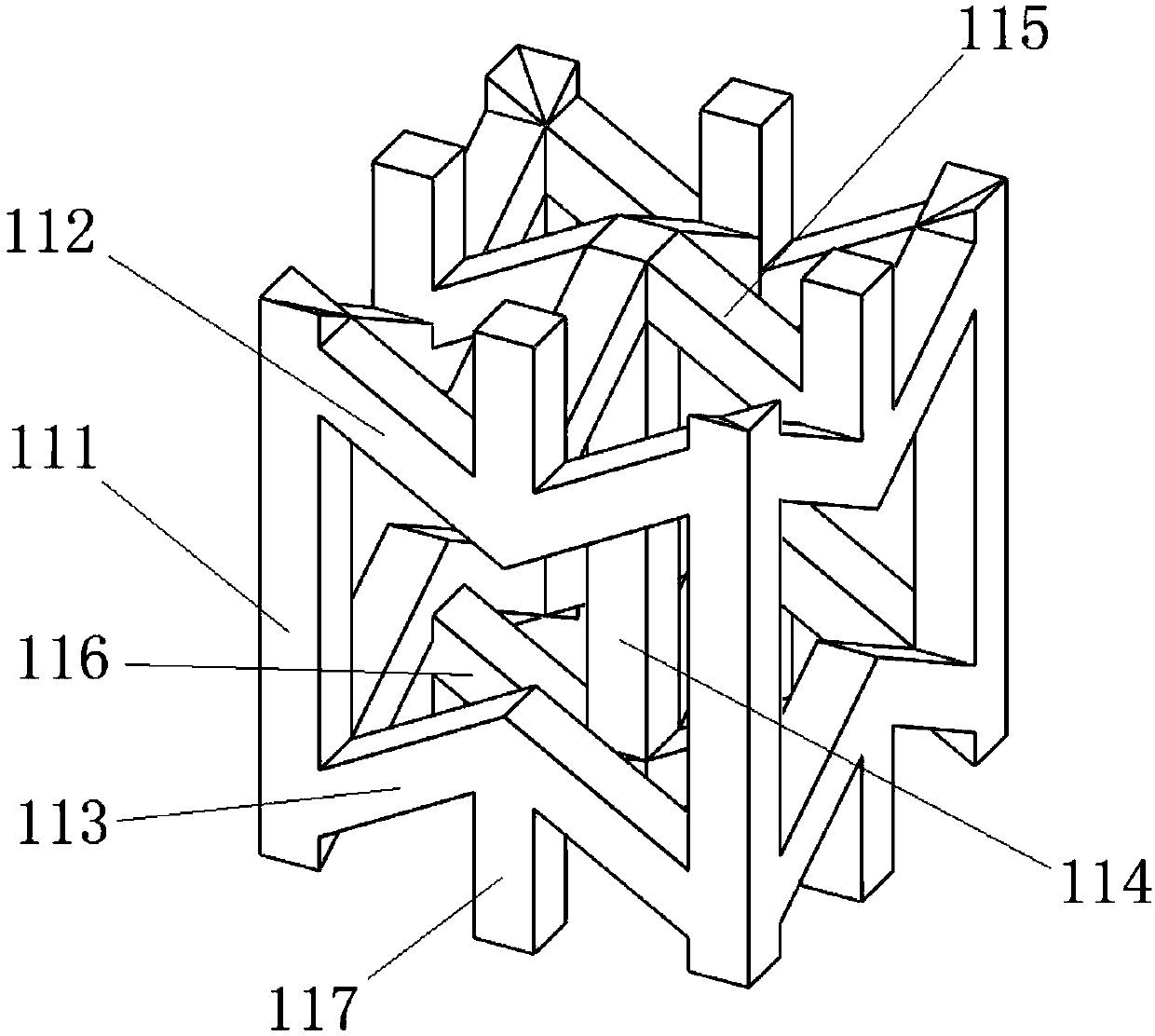

Embodiment 1

[0051] Draw the model of the honeycomb negative Poisson's ratio structure 11, use TC4 titanium alloy powder as raw material, process and shape it by 3D printing technology, and inject polycarbonate into the pores of the formed honeycomb negative Poisson's ratio structure 11 to form a composite sandwich core Layer 1, the composite sandwich layer 1 is fixed between the boron carbide ceramic face plate and the UHMWPE fiber buffer backboard in the form of seamless bonding to form an overall composite sandwich bulletproof structure.

Embodiment 2

[0053] The preparation method is the same as in Example 1, except that thermoplastic polyurethane elastomer rubber (TPU) is injected into the pores of the formed honeycomb-type negative Poisson's ratio structure 11 .

Embodiment 3

[0055] The preparation method is the same as in Example 1, except that epoxy resin is injected into the pores of the formed honeycomb-type negative Poisson's ratio structure 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com