Gelatinizing method for improving mold pressing binding force of metal part and plastic matrix

A technology for metal parts and plastic substrates is applied in the field of gluing for improving the bonding force between metal parts and plastic substrates. , The product quality is stable and good, and the effect of improving product reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

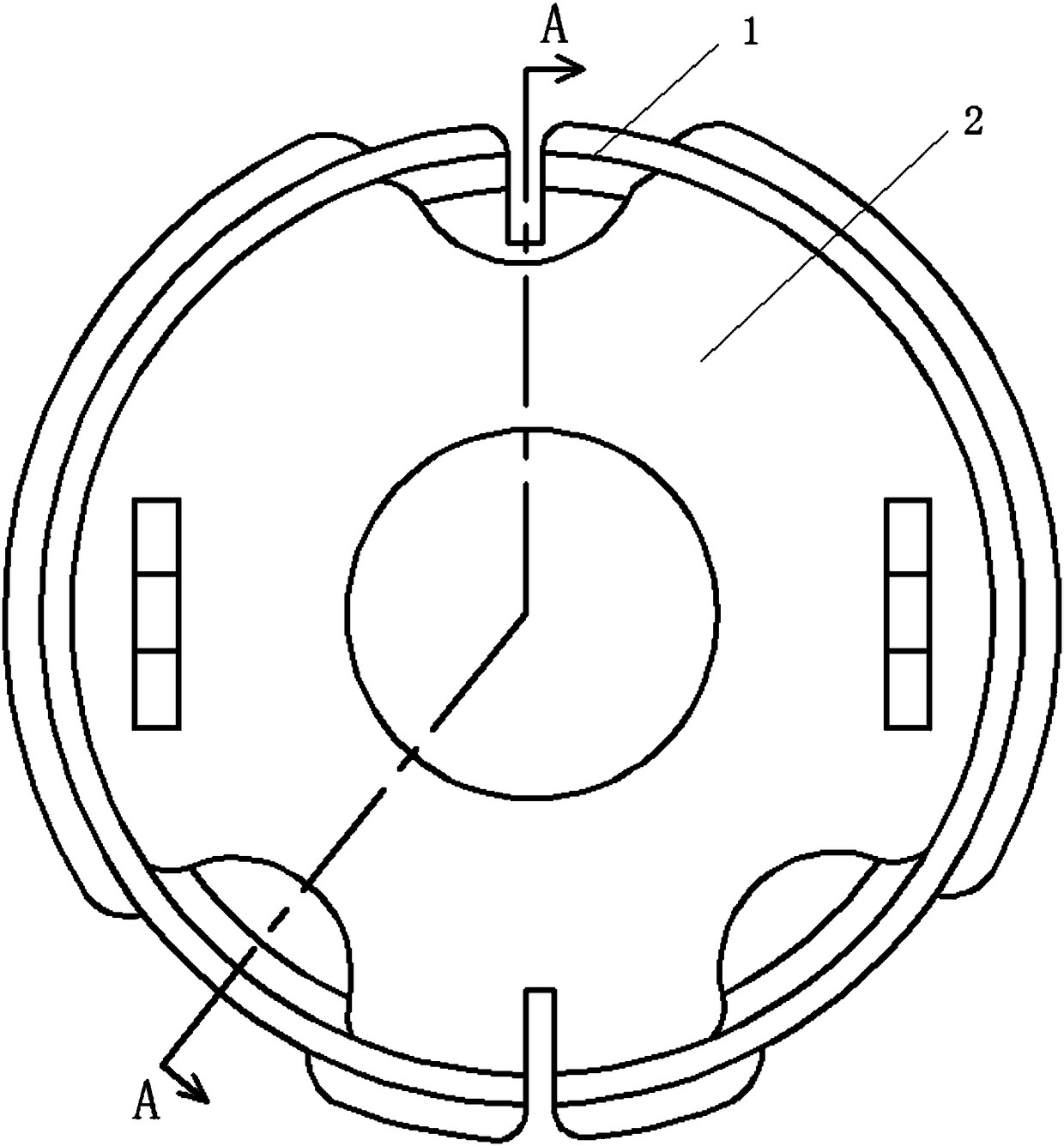

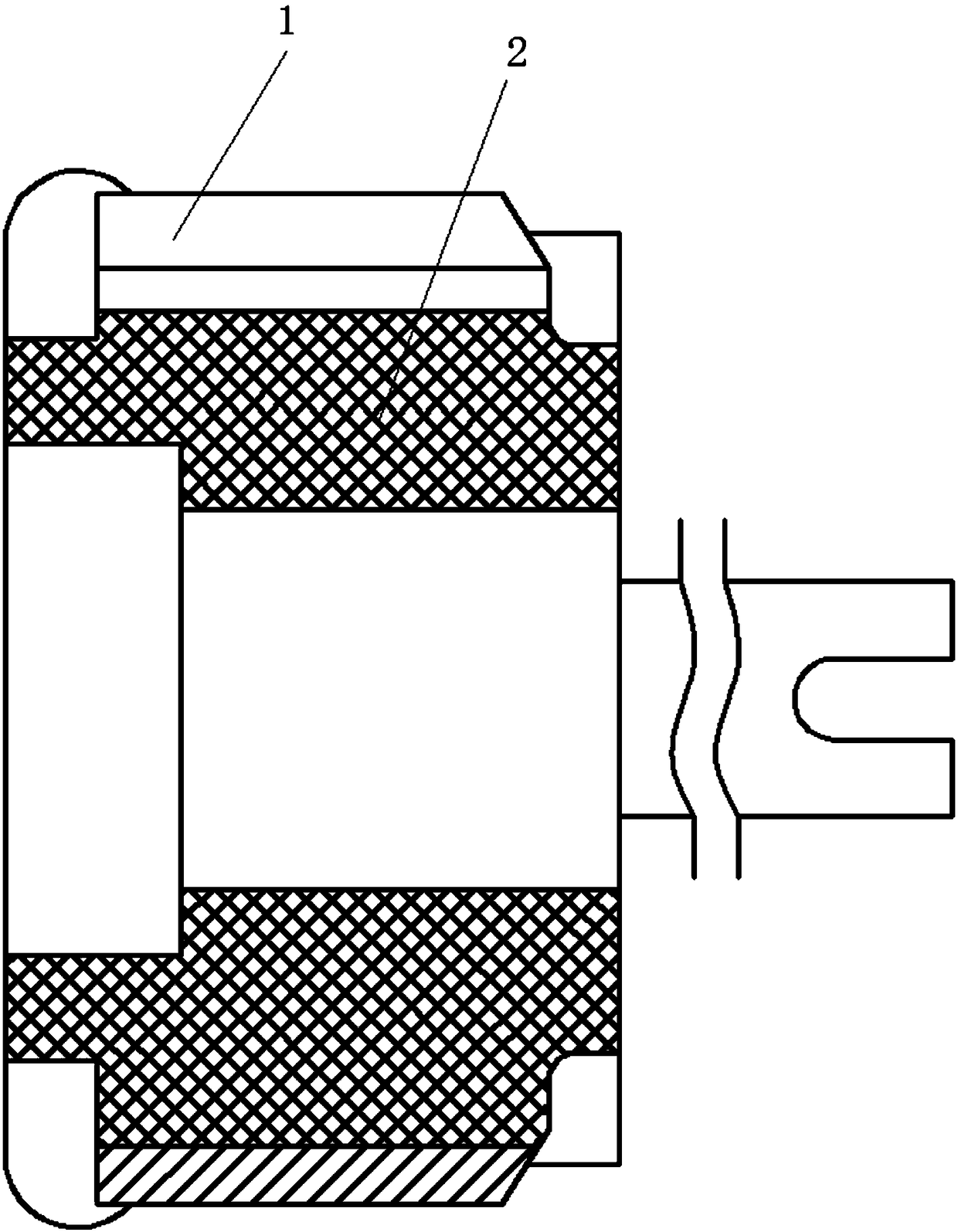

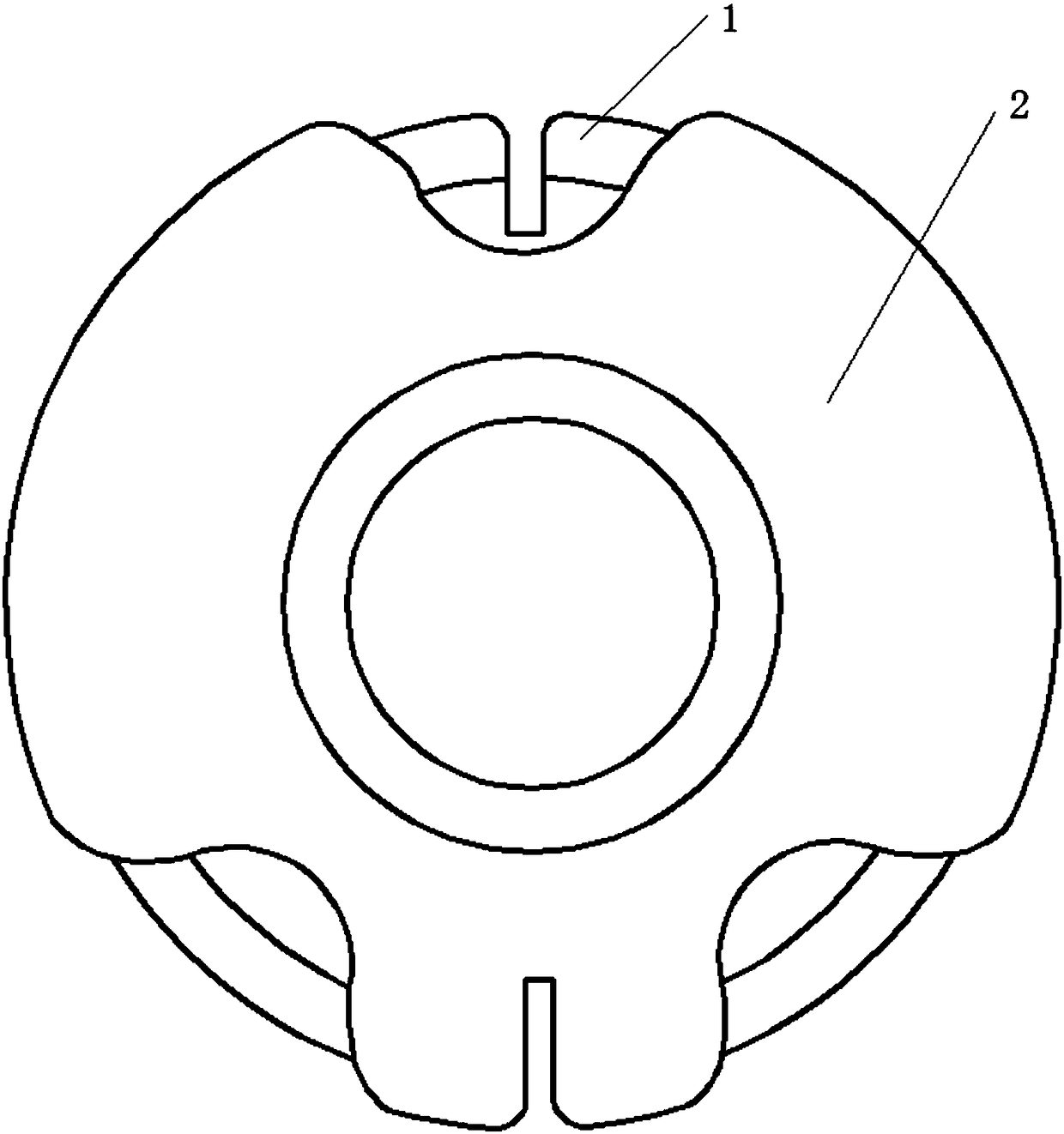

Image

Examples

Embodiment Construction

[0021] A first embodiment of the present invention is described below.

[0022] A glue coating method for improving the molded bonding force of metal parts and plastic substrates, comprising the following steps:

[0023] 1) Pre-treatment of metal parts: First, fill the container with an organic solvent, soak the metal parts in the organic solvent, take it out and brush the surface of the metal parts with a brush, and after cleaning and drying, place the metal parts in the Place a clean metal box on a heating plate and heat it for several minutes before taking it out; the organic solvent is gasoline, the heating temperature on the heating plate is 150°C, and the heating time is 8 minutes;

[0024] 2) Coating the glue for the first time: Take the metal parts, use a brush to evenly coat the first layer of glue along the molded joint surface of the metal parts and the plastic substrate, and place the metal parts coated with the first layer of glue Take it out after heating on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com