Self-running steel reel transport cart capable of steering actively

A technology for active steering and transport vehicles, applied in the direction of transporting passenger cars, bogies, motor vehicles, etc., can solve the problems of inability to turn, unsuitable for steel coil transportation, large turning radius, etc., and achieves improved adaptability, easy implementation, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below with reference to the accompanying drawings and examples. The principles and features of the present invention will be described below in conjunction with the accompanying drawings. It should be noted that the embodiments in the present application and the features in the embodiments can be combined without conflict. The examples given are only for explaining the present invention, not for limiting the scope of the present invention.

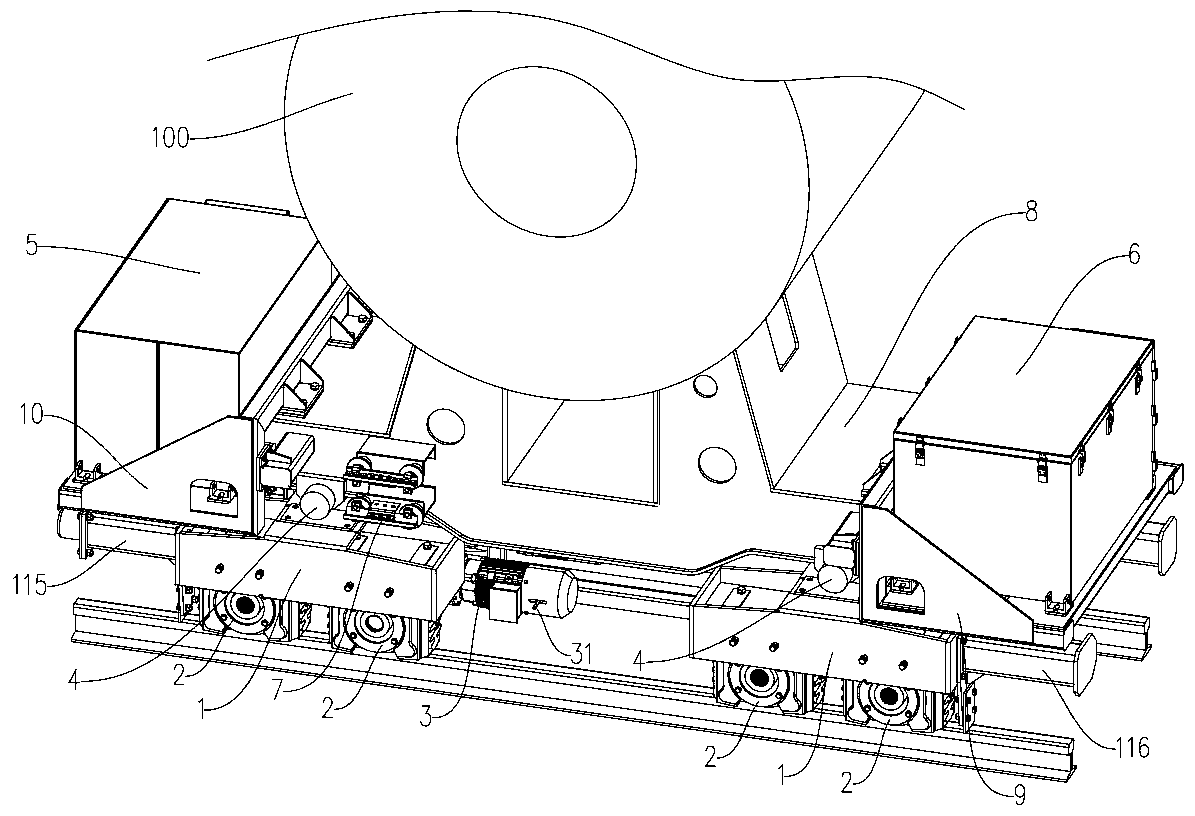

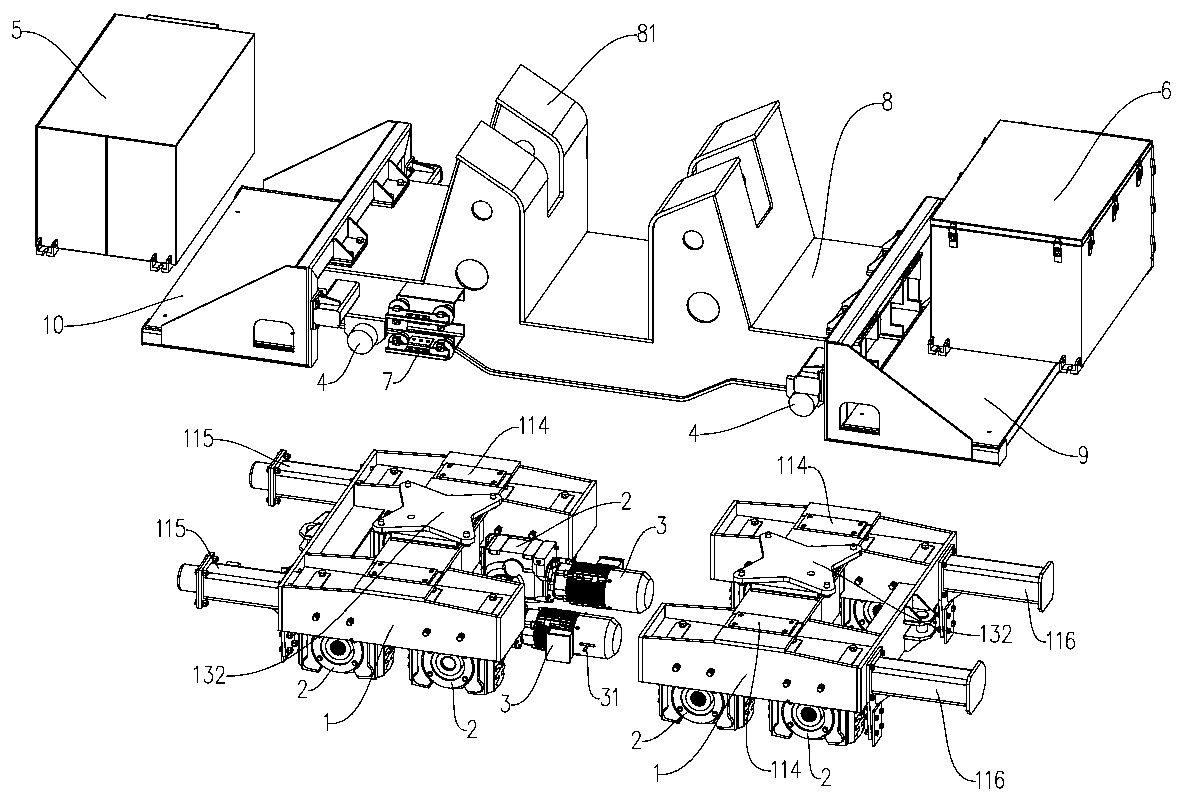

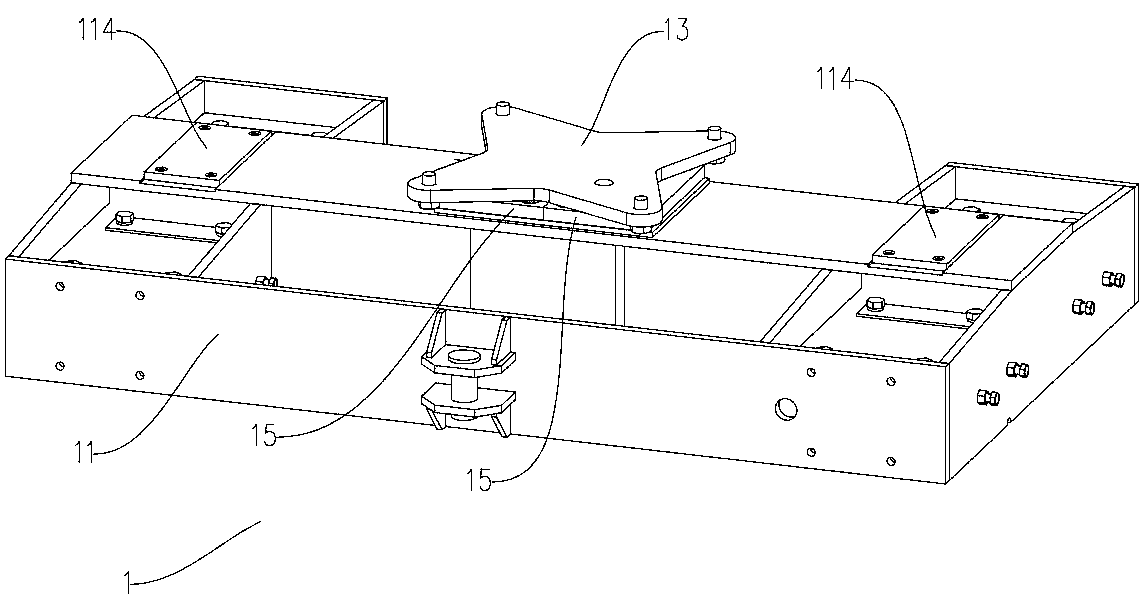

[0032] Please refer to Figure 1 to Figure 10 , figure 1 It is a schematic diagram of the overall three-dimensional structure of a specific embodiment of an actively steerable self-propelled steel coil transport vehicle provided by the present invention; figure 2 for figure 1 Partially disassembled schematic diagram of the specific embodiment shown; image 3 It is a three-dimensional structural schematic diagram of a specific embodiment of the bogie in a self-propelled steel coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com