A two-way reciprocating drilling three-stage reaming drilling tool and drilling method for large-caliber well completion in structural coal

A large-diameter, structural coal technology, applied in drilling equipment and methods, drill bits, earthwork drilling and mining, etc., can solve the problems of large-diameter hole formation difficulty, single reaming method, and low reaming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

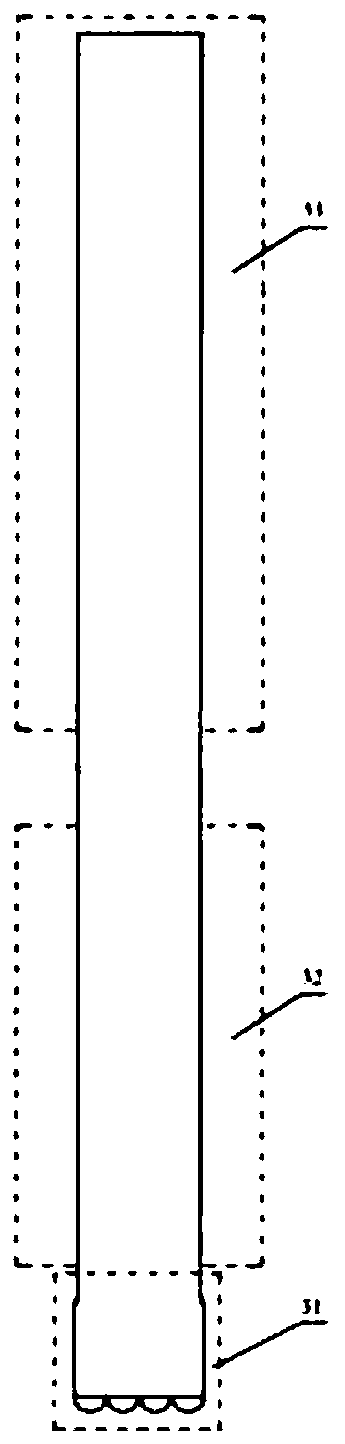

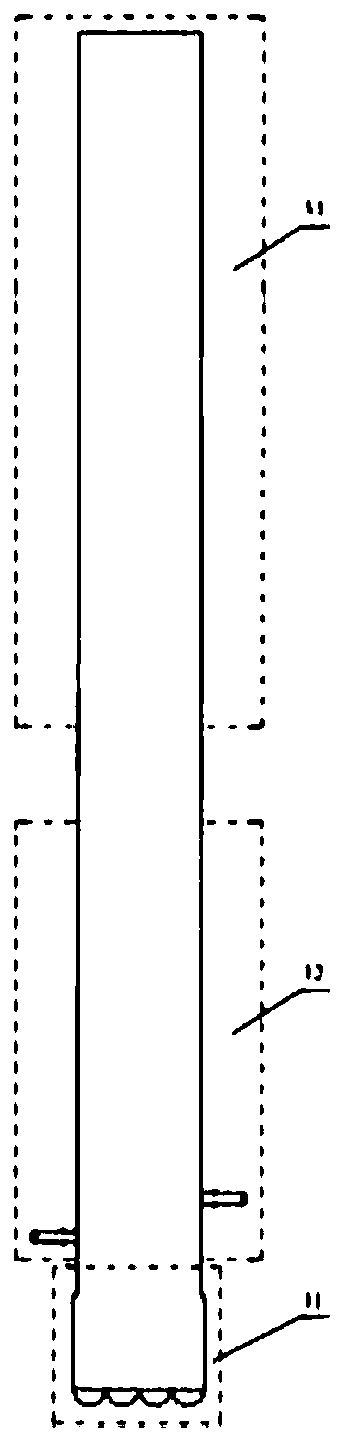

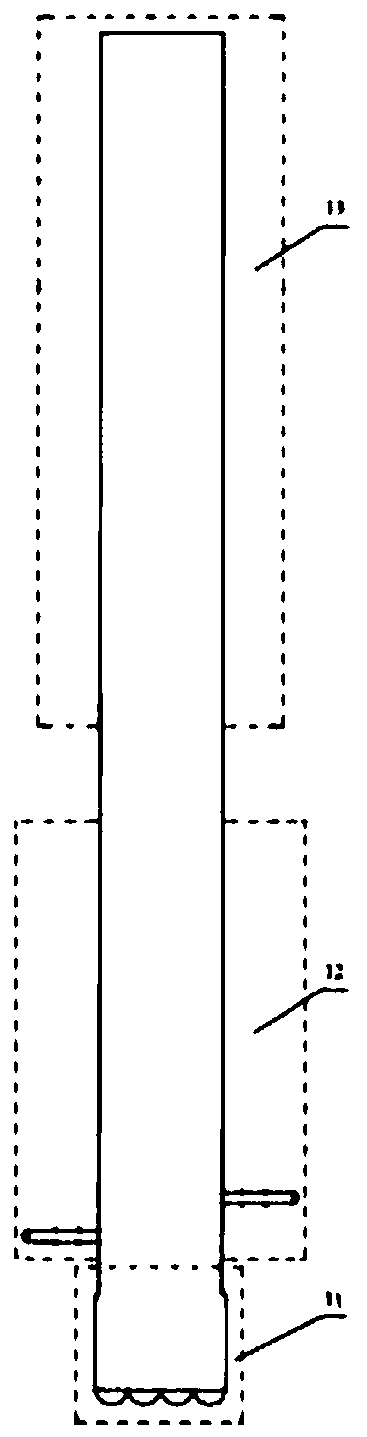

[0034] Such as Figure 5 As shown, the three-stage reaming drilling tool for two-way reciprocating drilling of structural coal large-diameter wells of the present invention includes a pilot hole assembly 31, a first-stage reaming recovery assembly 32 and a third-stage reaming recovery assembly 33 , wherein the pilot eye assembly 31 is connected with the first-level and second-level reaming recovery assembly 32, and the first-level and second-level reaming recovery assembly 32 is connected with the third-level reaming recovery assembly 33.

[0035] Such as Figure 8 , Figure 9 and Figure 10 The pilot eye assembly 31 is a drill bit 29;

[0036] Such as Figure 8 , Figure 9 and Figure 10 As mentioned above, the primary and secondary reaming recovery assembly 32 includes an outer shell 1, and the hollow interior of the outer shell 1 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com