Technology to eliminate interference clutters of self-corrected supersonic thickness measuring system

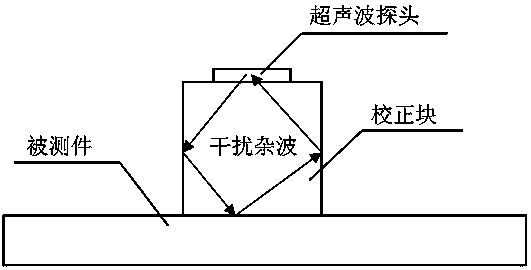

An ultrasonic and self-calibration technology, which is applied in the direction of using ultrasonic/sonic/infrasonic waves, measuring devices, instruments, etc., can solve the problems affecting the system's signal identification and interference, eliminate the influence of clutter on the measurement, and improve the detection accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] An embodiment of the invention is described in detail as follows:

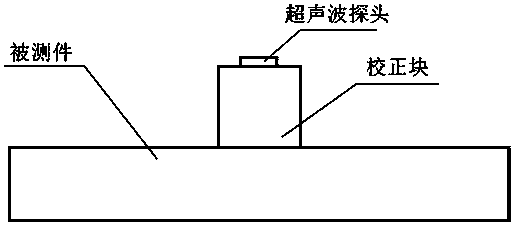

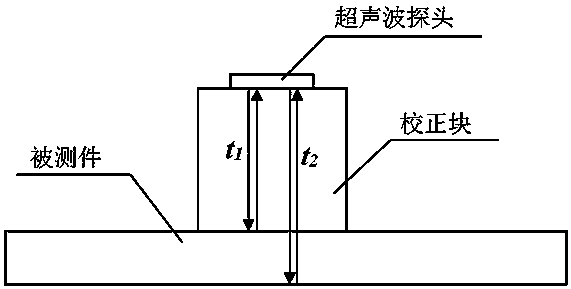

[0022] The present invention is an ultrasonic thickness measurement technology with self-correcting function, and the specific implementation steps are as follows:

[0023] (1) Select a metal plate with a thickness of 10mm as the object to be tested, and the material of the metal plate is No. 20 carbon steel. A correction block is processed by using No. 20 carbon steel. The shape of the correction block is cylindrical, the diameter is 10mm, and the thickness is 25mm. A thread with a pitch of 1mm is processed on the circumference of the correction block.

[0024] (2) Fix the ultrasonic probe on the upper surface of the calibration block, the ultrasonic wave generated by the ultrasonic probe has a wavelength of 1.2mm.

[0025] (3) Apply couplant on the lower surface of the calibration block to measure the thickness of the metal plate.

[0026] (4) Use the heater to heat the tested metal plate to change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com