Photoetching mask and recovery method for defect of same

A photolithography mask and repair method technology, applied in the field of photolithography mask and photolithography mask defect repair, can solve problems such as mask scrap, avoid imaging problems, improve quality, and improve accuracy and the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

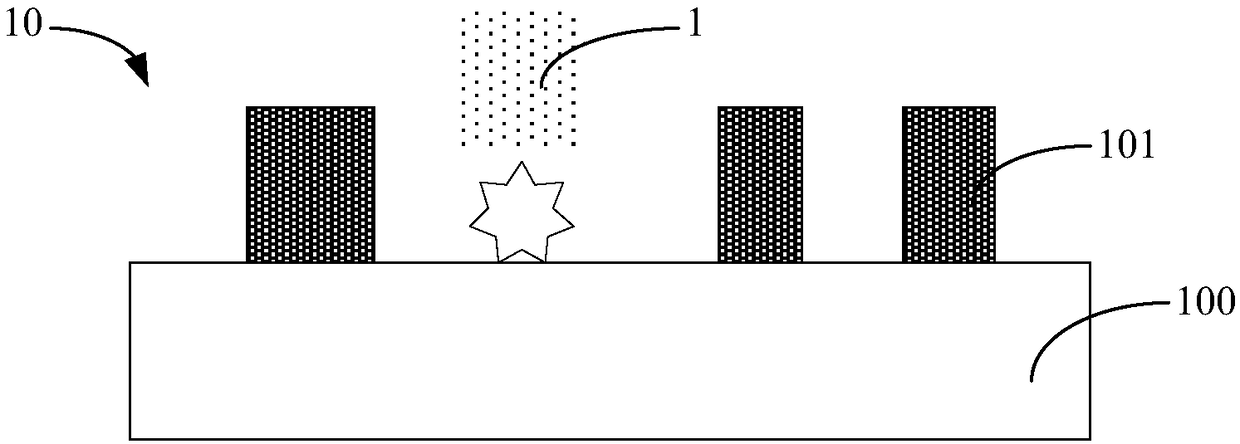

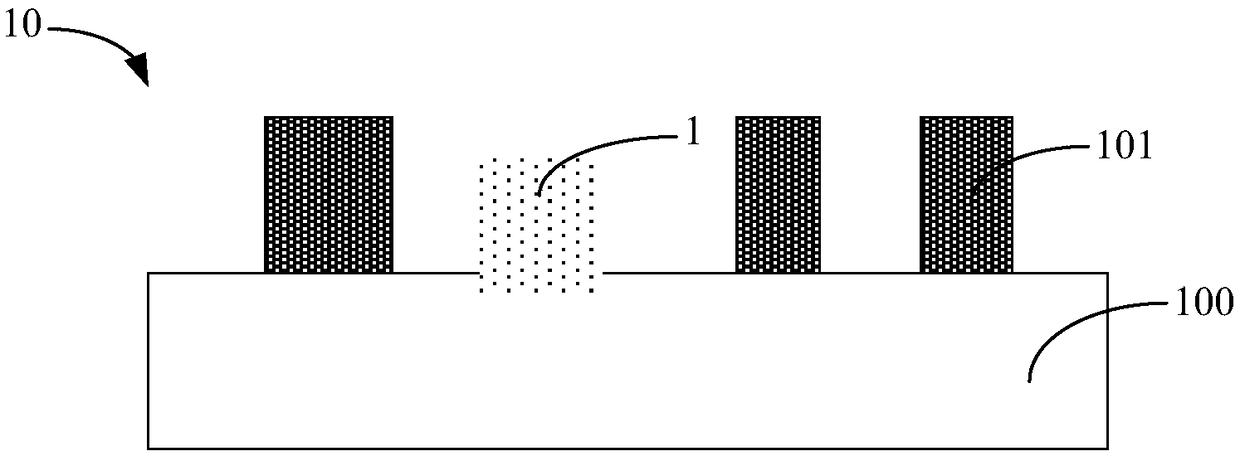

[0043] In order to solve the above-mentioned technical problems, the present invention provides a method for repairing photolithographic mask defects, such as figure 2 As shown, it mainly includes the following steps:

[0044] Step S1: providing a photolithographic mask, the photolithographic mask including a transparent substrate and a light-shielding pattern formed on the surface of the transparent substrate, wherein defective holes are formed on the transparent substrate outside the light-shielding pattern;

[0045] Step S2: forming a transparent material in the defect hole.

[0046] Through the repairing method of the present invention, a transparent material is formed in the defect hole on the transparent substrate of the photolithography mask, so as to reduce the incident light irradiated into the defect hole and the incident light irradiated on the surface of the transparent substrate outside the defect hole The optical path difference between them, thereby avoiding t...

Embodiment 2

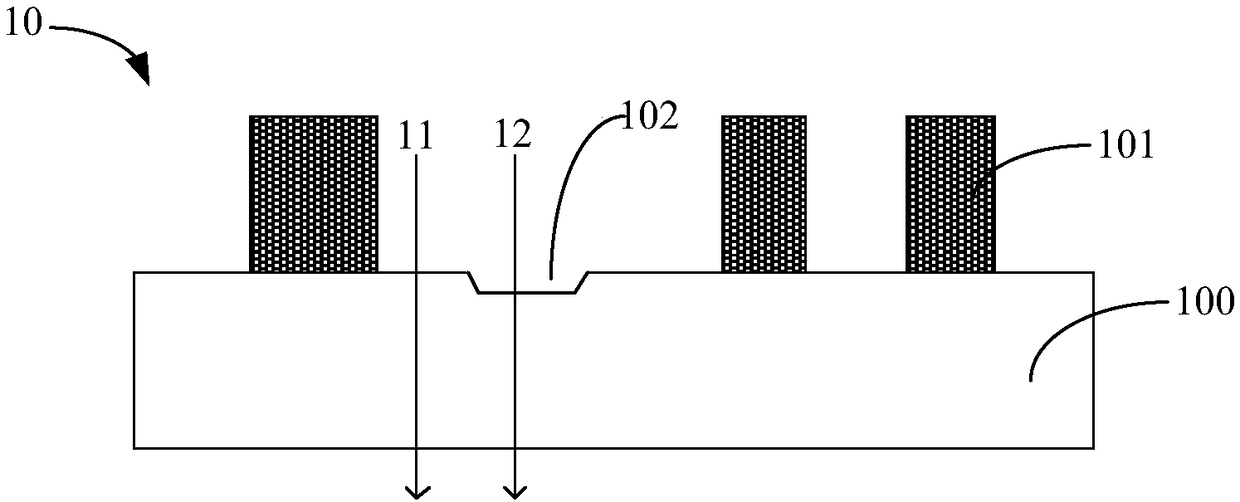

[0072] The present invention also provides a photolithography mask prepared by using the restoration method described in the first embodiment above.

[0073] like Figure 1E As shown, specifically, the photolithography mask 10 includes a transparent substrate 100 and a light-shielding pattern 101 formed on the surface of the transparent substrate 100, wherein defects are formed on the transparent substrate 100 outside the light-shielding pattern 101 A hole in which a transparent material 103 is formed.

[0074] The photolithographic mask plate 10 includes a flat plate with light transmission for exposure light, and at least one light-shielding pattern 101 with light-shielding property for exposure light, which can selectively block the photoresist on the surface of the wafer. Light, and finally form a corresponding pattern on the photoresist on the surface of the wafer.

[0075] The material of the transparent substrate 100 can be any suitable transparent material, among which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com