Graphene infrared sensor based on photonic crystal photoresponse enhancement technology and preparation method thereof

An infrared sensor and photonic crystal technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of inability to effectively distinguish infrared light, poor sensitivity and response speed, and low cost, and achieve wide-band photoresponse rate and preparation process Simple, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

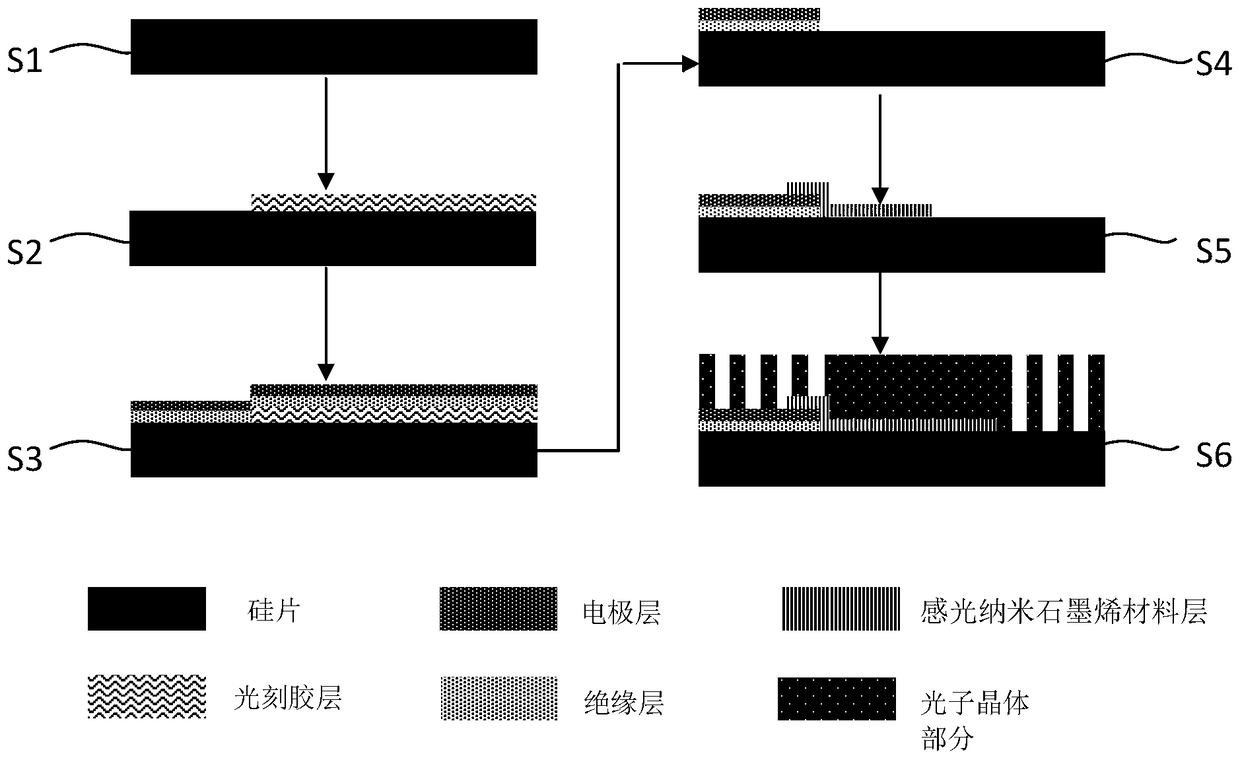

[0041] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

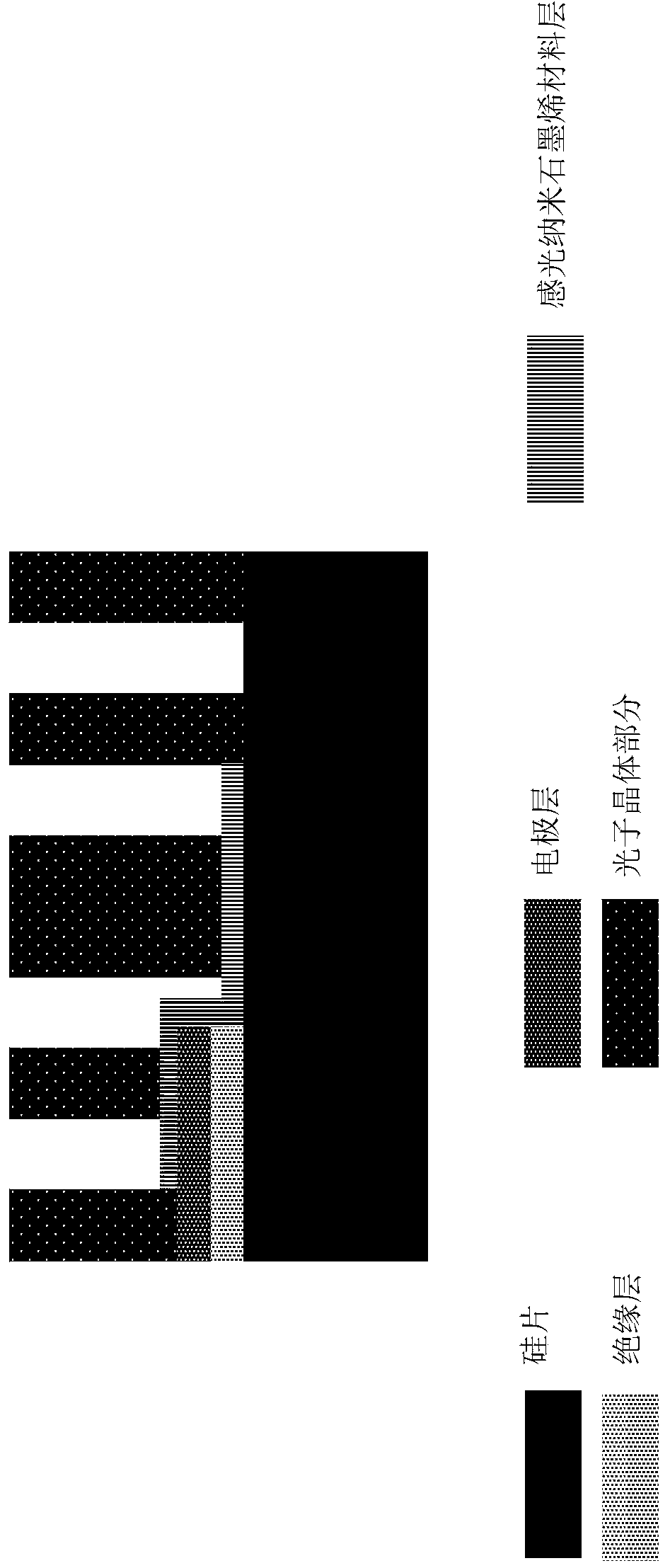

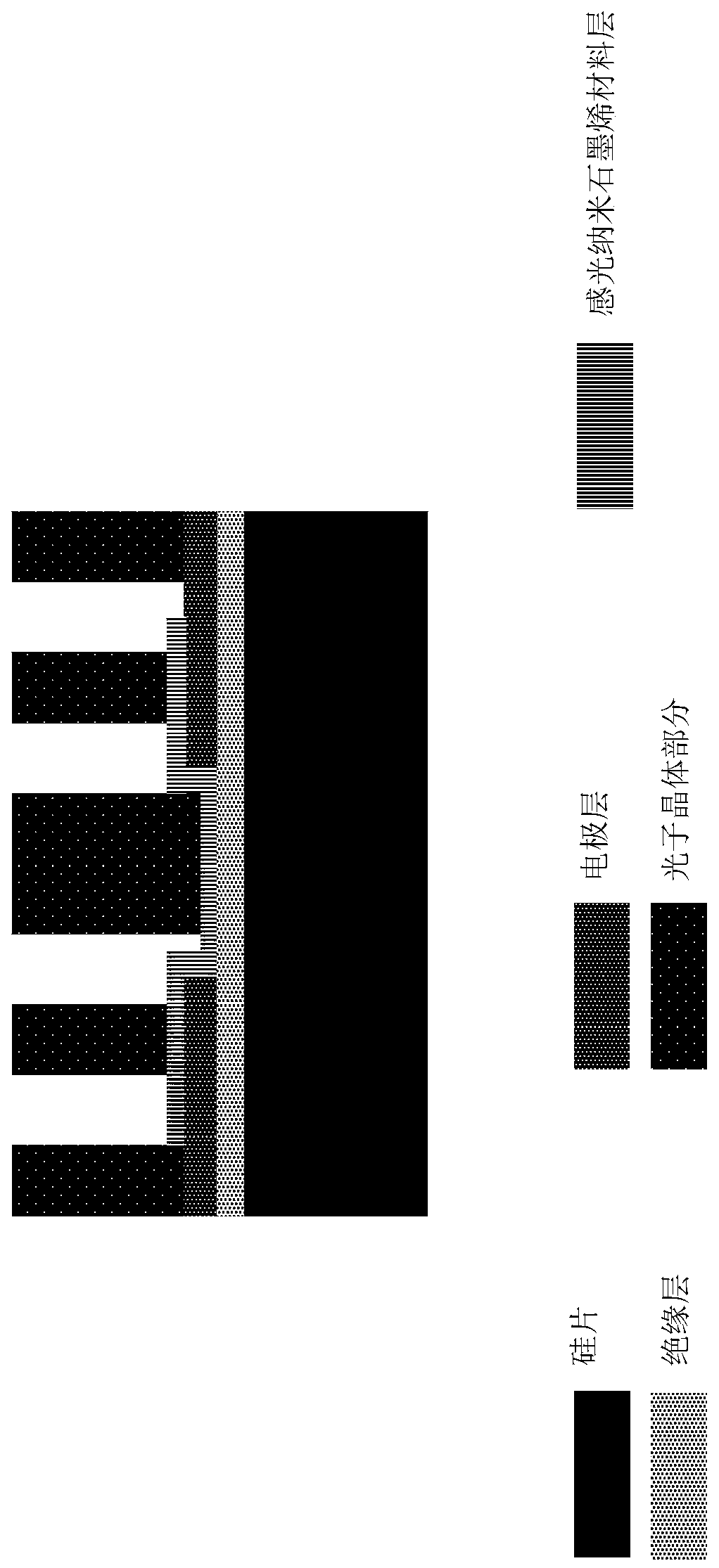

[0042] The object of the present invention is to provide a graphene infrared sensor based on photonic crystal photoresponse enhancement technology, which is prepared by a photonic response amplification method for specific wavelength infrared rays, and by designing photonic crystal structure and size to produce higher sensitivity photoelectric sensor. For infrared rays of a specific wavelength, by designing the period of the photonic crystal and the position and size of the defect, the photonic crystal can focus the incident infrared rays on the graphene surface to achieve the purpose of enhancing the photoresponsivity. After graphene absorbs infrared energy, photoinduced carriers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com