Gluten forming machine

A molding machine and gluten technology, applied in the direction of food molding, vegetable protein processing, food science, etc., can solve the problems of inability to accurately control the shape of gluten finished products, low output, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

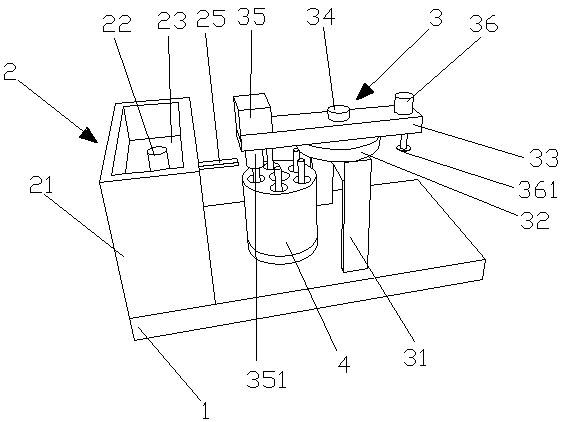

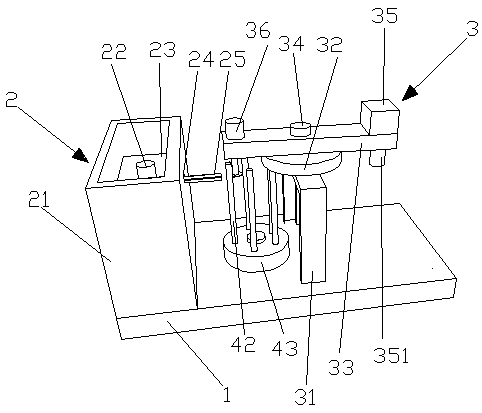

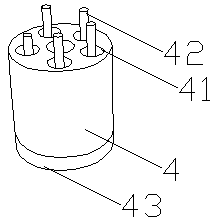

[0022] Such as Figure 1-4 As shown, a kind of gluten molding machine of the present invention comprises frame 1, and is provided with gluten extruding device 2 and gluten molding device 3 on frame 1, and gluten extruding device 2 comprises hopper 21, and the bottom of hopper 21 is fixed A cylinder 22 is provided, and a pressure plate 23 is provided on the cylinder 22. A discharge port 24 is also provided on the side wall of the material box 21. The discharge port 24 faces the direction of the gluten forming device 3. The discharge port 24 is provided with a material guide tube 25 , the gluten forming device 3 comprises a forming frame 31, the top of the forming frame 31 is provided with a connecting rod seat 32, a connecting rod 33 is movably arranged on the connecting rod seat 32, and the connecting rod 33 is rotated on the connecting rod seat 32 by a rotating shaft 34, The two ends of the connecting rod 33 are respectively provided with a cylinder 35 and a motor 36, the cyl...

Embodiment 2

[0024] The frame 1 is provided with a gluten extruding device 2 and a gluten forming device 3, the gluten extruding device 2 includes a material box 21, the bottom of the material box 21 is fixedly provided with a cylinder 22, the cylinder 22 is provided with a pressing plate 23, and the material box 21 The side wall is also provided with a discharge port 24, the discharge port 24 faces the gluten forming device 3 direction, the discharge port 24 is provided with a feed pipe 25, the gluten forming device 3 includes a forming frame 31, and the top of the forming frame 31 is provided with Connecting rod seat 32, connecting rod 33 is movably arranged on connecting rod seat 32, and connecting rod 33 is arranged on connecting rod seat 32 by rotating shaft 34, and the two ends of connecting rod 33 are provided with cylinder 35 and motor 36 respectively, and cylinder 35 Gluten extruding rollers 351 are also provided on the top, and cutting blades 361 are also provided on the output sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com