A kind of emulsion system and preparation method thereof

An emulsion system and aqueous solution technology, applied in mixing methods, chemical instruments and methods, dissolution and other directions, can solve the problems of poor emulsifiability and poor stability, and achieve the effects of short emulsification time, stable performance, and prevention of tripeptide denaturation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a method for preparing an emulsion system, the specific steps comprising:

[0021] 1) mixing lysine-tyrosine-tryptophan tripeptide with distilled water to obtain tripeptide aqueous solution;

[0022] 2) Under the conditions of an ice-water bath and high-field-strength ultrasound, the tripeptide aqueous solution obtained in step 1) is emulsified with the oil phase to obtain an emulsion system; the field strength of the high-field-strength ultrasound is 10 to 1000 W·cm -2 .

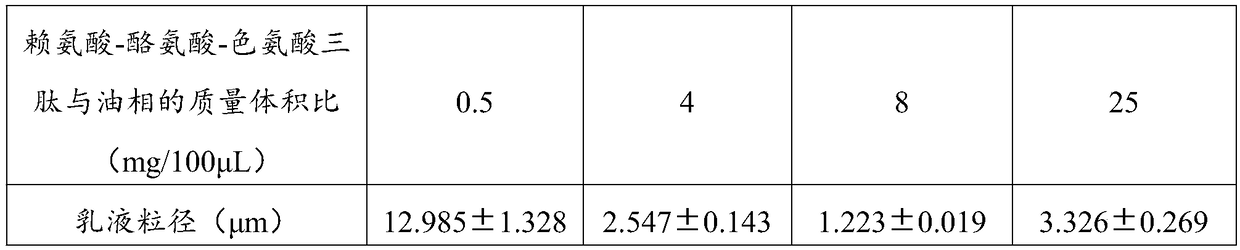

[0023] The invention mixes the lysine-tyrosine-tryptophan tripeptide with distilled water to obtain tripeptide aqueous solution. In the present invention, the mass ratio of the lysine-tyrosine-tryptophan tripeptide to distilled water is preferably 1-10 mg: 1 mL, more preferably 6-9 mg: 1 mL, most preferably 8 mg: 1 mL . The present invention does not have any special limitation on the source of the lysine-tyrosine-tryptophan tripeptide, and commercially available products we...

Embodiment 1

[0034] Take 4 mg of lysine-tyrosine-tryptophan tripeptide in a 1.5 mL centrifuge tube, add 1 mL of distilled water and vortex on a vortex mixer for 5 min; A small probe with a diameter of 3mm is installed on the equipment, the ultrasonic frequency is set to 20kHz, the ultrasonic intensity is 300W, the centrifuge tube is fixed, and kept in an ice-water bath, and the emulsion system is obtained after ultrasonic treatment for 10s.

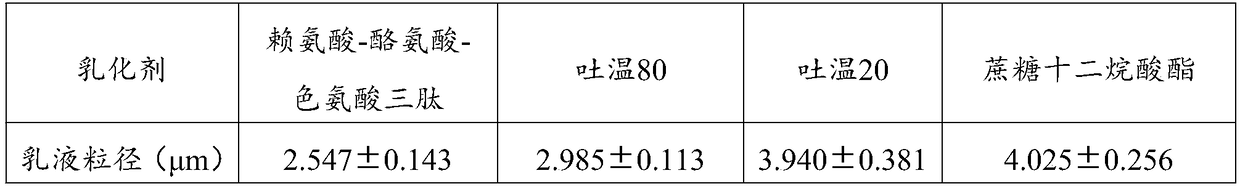

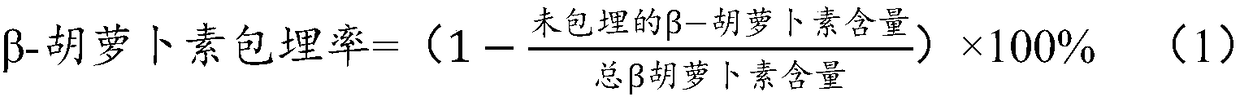

[0035] After the emulsion system was prepared, the particle size was measured by a Mastersizer 2000 laser particle size distribution analyzer, expressed by volume-average diameter (D43). Particle size is the average of 3 readings, as shown in Table 1. The measurement parameters are as follows: refractive index: 1.450, absorption parameter: 0.010, rotational speed: 2000r / min.

Embodiment 2

[0037] Take 6 mg of lysine-tyrosine-tryptophan tripeptide in a 1.5 mL centrifuge tube, add 1 mL of distilled water and vortex on a vortex mixer for 4 min; A small probe with a diameter of 4mm is installed on the equipment, the ultrasonic frequency is set to 18kHz, the ultrasonic intensity is 400W, the centrifuge tube is fixed, and kept in an ice-water bath, ultrasonically treated for 8s to obtain the emulsion system. After the emulsion system was prepared, the particle size was measured by the particle size measurement method in Example 1, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| embedding rate | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com