Machining method of 2024 aluminum alloy free forged piece

A processing method and free technology, applied in the field of aluminum alloy processing, can solve problems such as the limitation of 2024 aluminum alloy application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The core of the present invention is to provide a processing method of 2024 aluminum alloy free forging, so as to realize the processing of 2024 aluminum alloy free forging, thereby broadening the application field of 2024 aluminum alloy.

[0024] In order to enable those skilled in the art to better understand the technical solutions provided by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

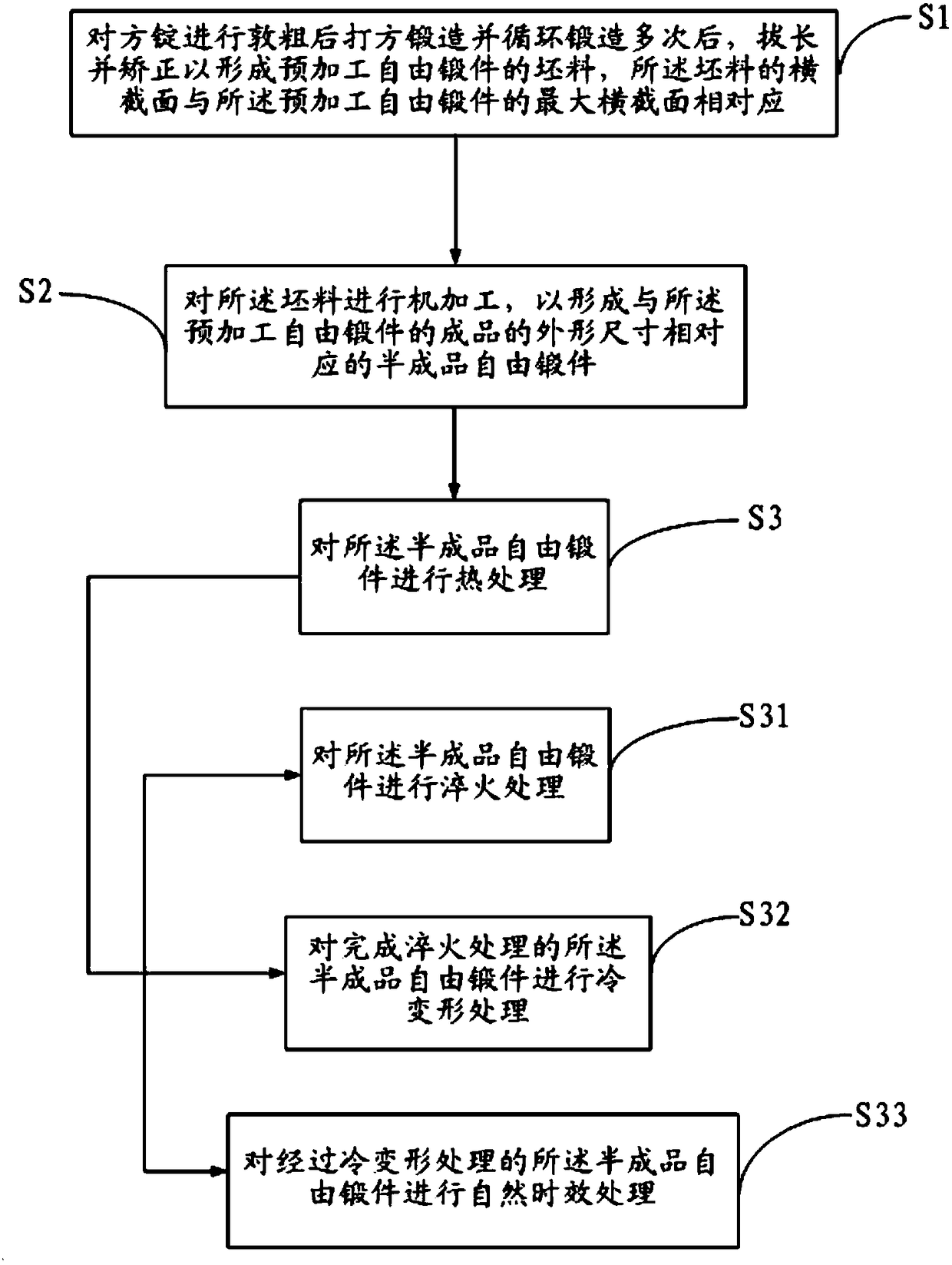

[0025] Such as figure 1 As shown, a method for processing a 2024 aluminum alloy free forging provided in an embodiment of the present invention, the method includes steps:

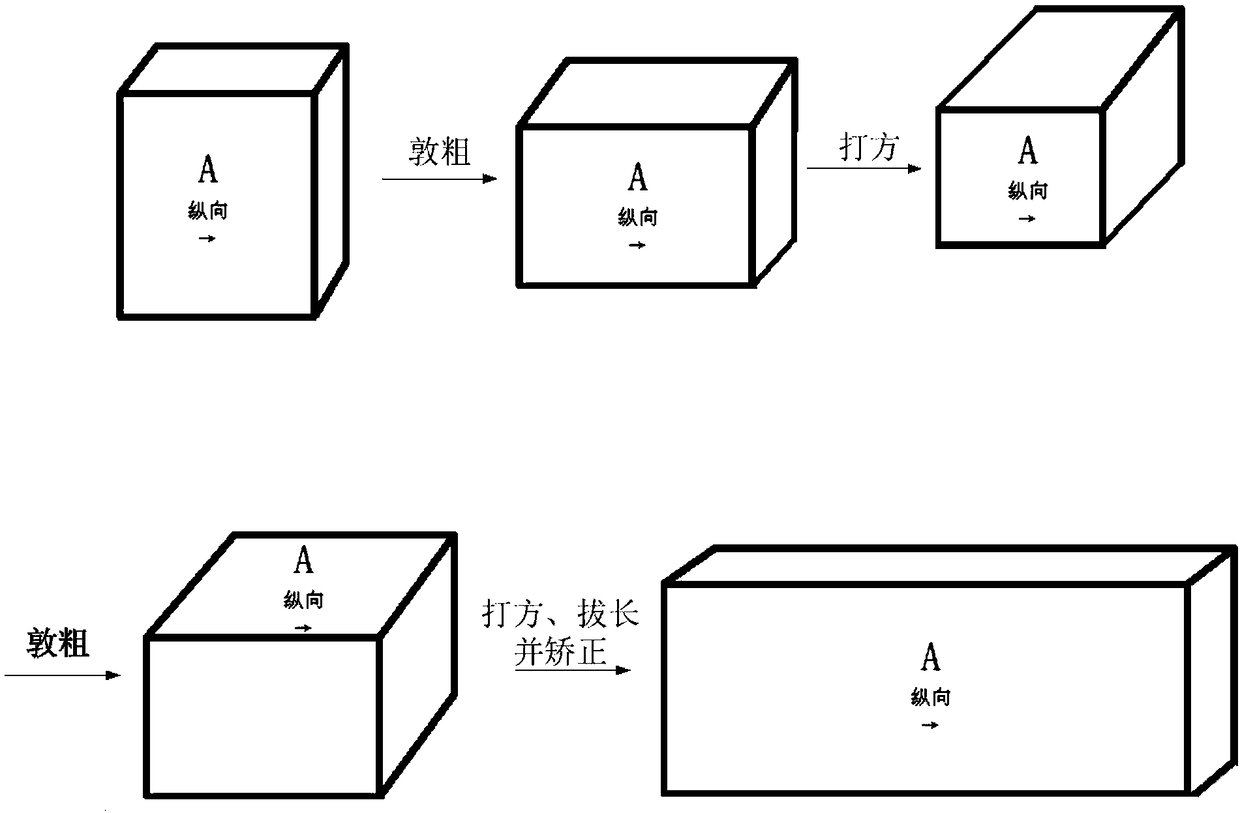

[0026] Step S1: After thickening the square ingot, square forging and cycle forging several times, elongate and straighten to form the billet of the pre-processed free forging, the cross section of the billet corresponds to the largest cross-section of the pre-processed free forging, of course here ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com