Aluminium alloy with intergranular corrosion resistance, metods of manufacture and its use

A technology of aluminum alloy and alloy, which is applied in the field of aluminum alloy and can solve problems such as grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] DESCRIPTION OF THE PREFERRED EMBODIMENT

[0040] The present invention has significant advantages in the field of corrosion-resistant aluminum alloys, in particular for the manufacture of round and flat tubes, for example for heat exchanger applications such as those used in vehicles such as condensers and others Uses, such as air conditioners, refrigerators, etc.

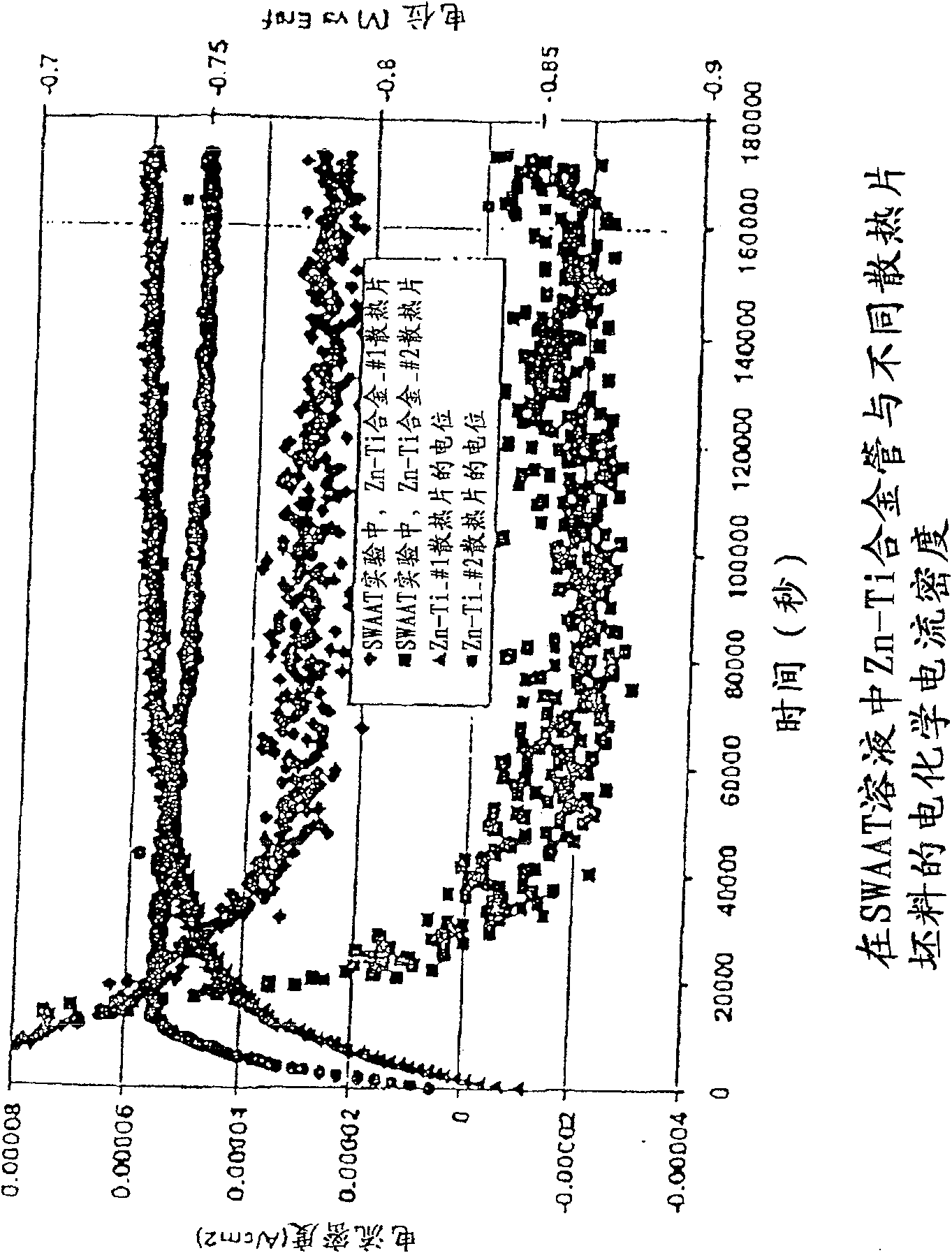

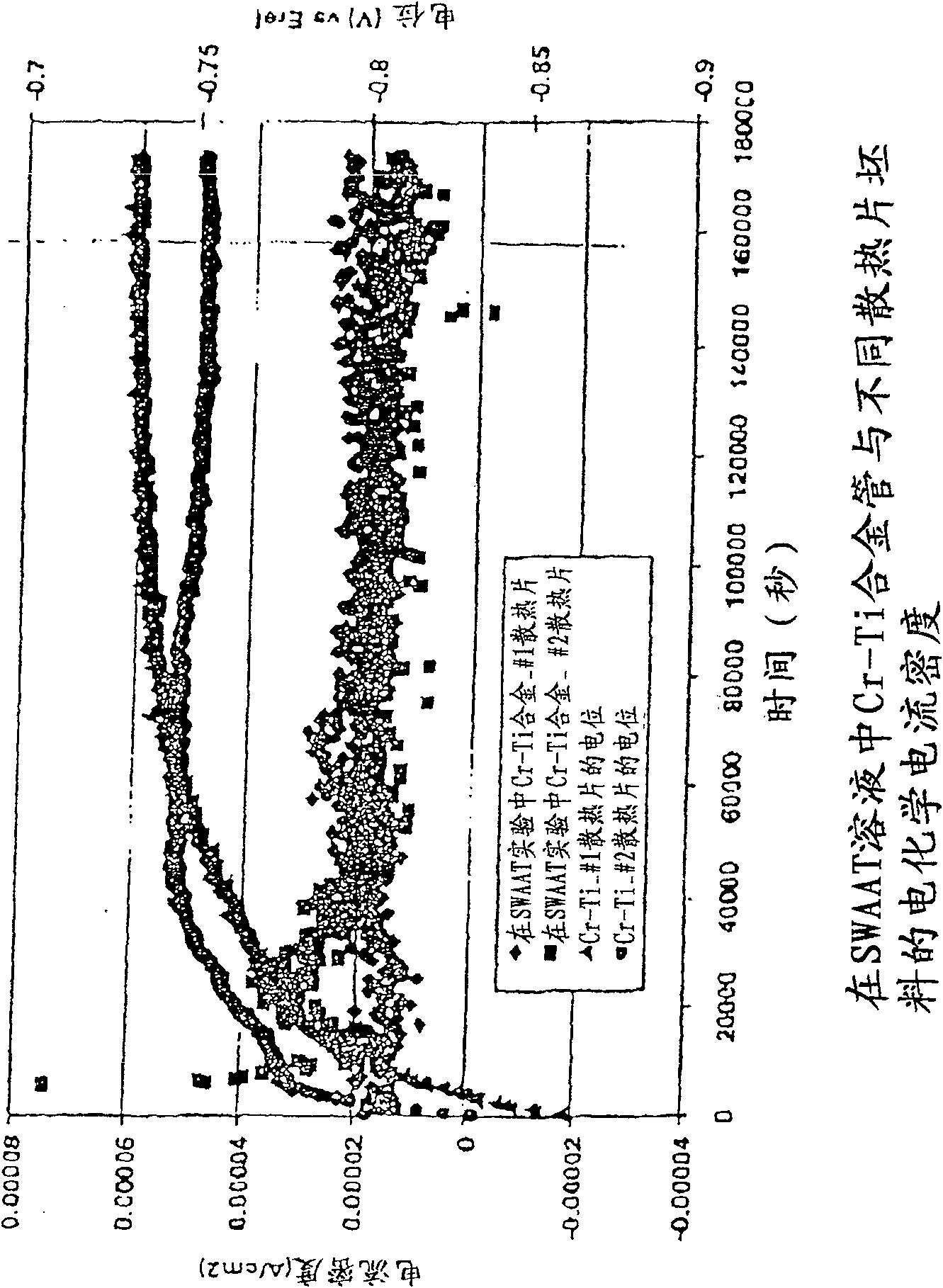

[0041] The present invention is different from the prior art of improving corrosion resistance by controlling the chemical composition of intermetallic compounds and obtaining fine grain size. The alloy of the present invention utilizes the content and ratio of alloying elements so that the electrical properties of the alloy matrix and grain boundaries The chemical potential is matched. By specifying / controlling the amount and ratio of alloying elements, a balance can be established between the electrochemical potential of the matrix and the grain boundary, that is, the corrosion potential difference between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com