A kind of treatment method of carbendazim wastewater

A treatment method, carbendazim technology, applied in the field of carbendazim wastewater treatment, can solve the problems of cumbersome process, large equipment investment, and large investment cost, and achieve the effect of simple process, low operating cost, and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

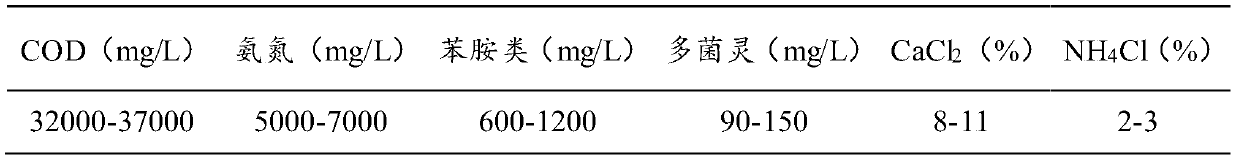

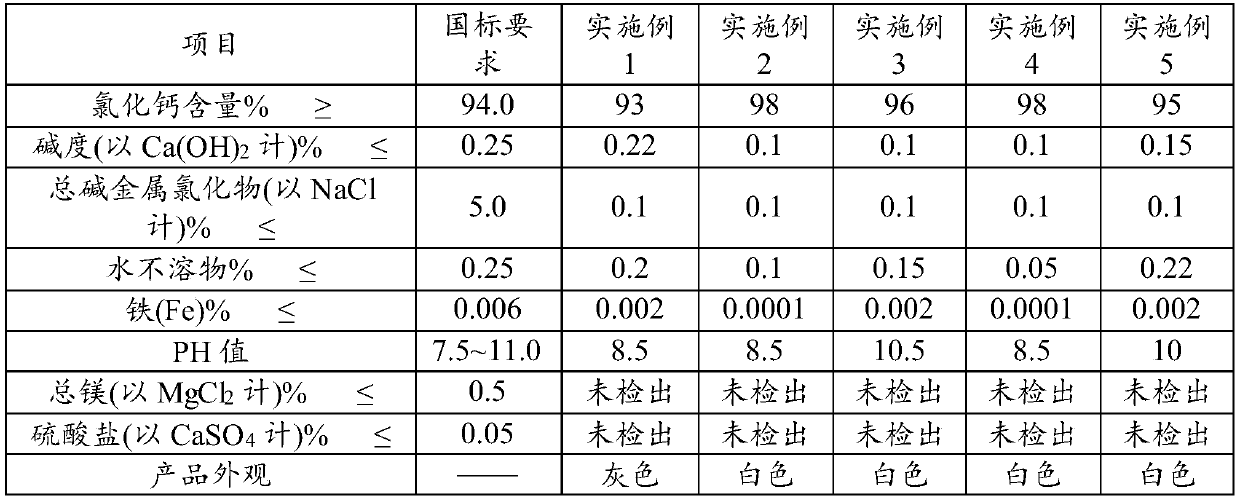

[0080] Take 1000g of carbendazim wastewater and perform high-temperature oxidation. The temperature of high-temperature oxidation is 600° C. for 1 hour to obtain 106 g of calcium chloride product with a content of 97%, and the color of the product is gray.

[0081] The performance indexes of the anhydrous calcium chloride product obtained in Example 1 of the present invention are shown in Table 3.

Embodiment 2

[0083] (1) Take 1000g of carbendazim wastewater, add 27g of calcium oxide, adjust the pH to 12, heat to 60°C, and then blow air into the bubbling, the bubbling air flow rate is 1000mL / min, and the bubbling time is 60min The ammonia gas in the carbendazim wastewater is obtained to obtain deammoniated wastewater; the tail gas produced is absorbed by dilute hydrochloric acid to obtain ammonium chloride as a by-product.

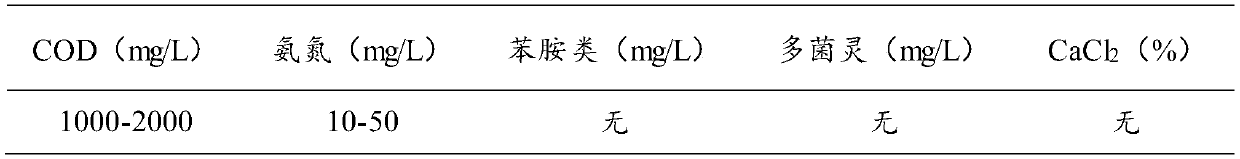

[0084] (2) carry out ion analysis to the waste water after the deamination that step (1) obtains, according to the analysis data of calcium ion and chloride ion, supplement hydrochloric acid or calcium oxide, the mol ratio of calcium ion and chloride ion is adjusted to 1:2, Then concentrate, the concentration rate is 3 times, respectively to obtain fraction 692g and concentrated solution 335g; wherein, the pH value of the fraction is 6.0~6.5, the color is colorless and transparent, and the main components of the fraction are shown in Table 2;

[0085] The main co...

Embodiment 3

[0091] Take 1000g of carbendazim wastewater and perform high-temperature oxidation. The temperature of high-temperature oxidation is 800° C. for 1 hour to obtain 106 g of calcium chloride product with a content of 96%, and the color of the product is white.

[0092] The performance indexes of the anhydrous calcium chloride product obtained in Example 3 of the present invention are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com