Patents

Literature

78 results about "Carbendazole" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cuttage and breeding method for sabina vulgalis

InactiveCN101699955AImprove survival rateHigh reproductive coefficientCultivating equipmentsHorticultureShootGrowth hormone

A cuttage and breeding method for sabina vulgalis comprises the steps of renovating a cuttage bed, picking branches, processing shoot for cutting, performing cuttage and the like; deeply ploughing a seedling tray, clearing off impurities, applying cottage, leveling, widening to make a lower bed, and paving clean river sand on the seedling bed; sterilizing the sand bed which is 5-10cm thick with 800-1000 times of carbendazol liquid medicine; picking 1-2 years old healthy and strong branches without diseases or pests at dawn, putting the branches cut down in a plastic cask constraining water timely to prevent drying-up due to water loss; processing shoot for cutting by adopting different medicines and plant growing hormone with concentration being 50-150ppm for dipping for 2-6h, so that breeding coefficient is higher. Facts prove that the cuttage and breeding survival rate of sabina vulgalis bred by using the invention can reach up to 75-89%, thus realizing the aim of enhancing breeding coefficient.

Owner:GANSU PROVINCE ACAD OF QILIAN WATER RESOURCE CONSERVATION FORESTS RES INST

Chinese rose water planting cutting propagation method

InactiveCN104303969ATake root fastWide variety of applicationsPlant cultivationCultivating equipmentsNutritionInsect pest

A Chinese rose water planting cutting propagation method belongs to the field of research on plant propagation and aims to solve the problems that in Chinese rose cutting, the humidity and temperature are hard to control, a cutting base substrate easily carries diseases and insect pests, the cutting nutrition is quickly consumed and the like. The method can realize the cutting propagation annually, is good in environment controllability and has the survival rate of more than 95%. The method comprises the steps of selection and processing of cutting slips, preparation of a nutrient solution, water planting, daily management and seedling hardening and transplanting. The cutting slips are cut by 10-15cm, and are soaked in a 500-diluted 30% carbendazin emulsion for 5-15 minutes, the lower parts of the cutting slips are soaked in a 30-50mg / Kg ABT NO.2 rooting powder solution for 2-4 hours, are placed into a self-made cutting box, and are cultured by a 1 / 2 Hoagland nutrient solution of which the temperature is 20-25 DEG C, the cutting slips are aerated by 2-3 times every day, the nutrient solution is replaced every 7 days, when cutting seedling roots grow to 1-2cm long, the cutting slips are transplanted into a field, and are watered once every day, the watering frequency is gradually reduced after four days, direct light is avoided, and the cutting slips can survive in 8-10 days.

Owner:LINYI UNIVERSITY

A kind of bactericidal composition containing prothioconazole

The invention relates to a bactericidal composition containing prothioconazole, which contains active ingredient A and active ingredient B, wherein active ingredient A is selected from prothioconazole, and active ingredient B is selected from thiophanate-methyl, multibacterium One of Ling and prochloraz, wherein the weight ratio of active ingredient A to active ingredient B is 1:80 to 80:1, made into wettable powder, water dispersible granule, suspending agent, suspoemulsion, water emulsion, Microemulsion, used to control powdery mildew, sheath blight, fusarium wilt, leaf spot, rust, sclerotinia, viral disease, anthracnose, gray mold, ring spot, bakanae disease, rice blast, early blight, Diseases such as green mold, pedicle rot, penicillium, flax spot, scab, blight, etc. have the characteristics of small dosage, resistance to rain erosion, and obvious synergistic effects.

Owner:SHAANXI MEIBANG PHARMA GRP CO LTD

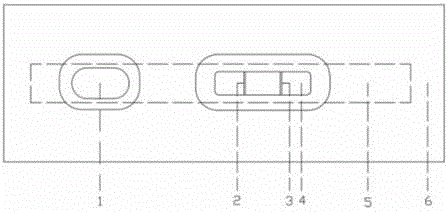

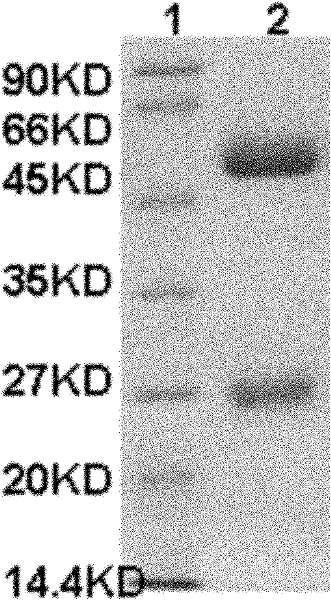

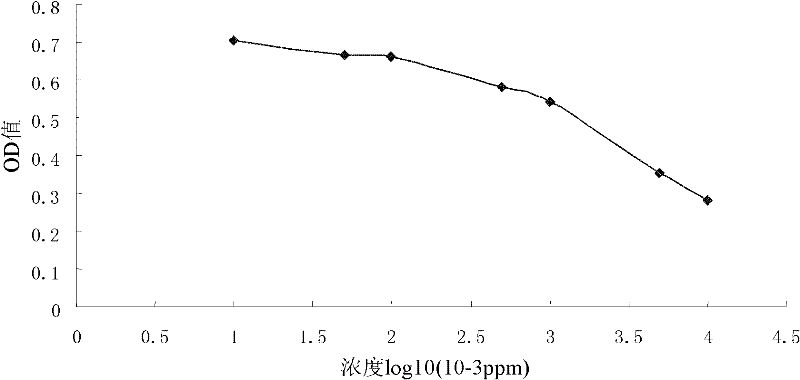

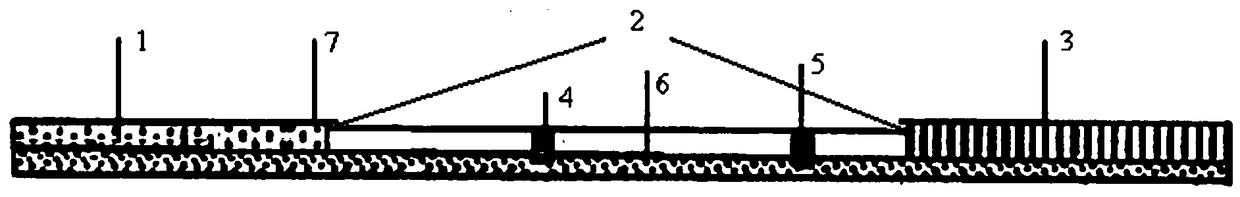

Immune colloidal gold detecting card of carbendazin and preparation method of immune colloidal gold detecting card

The invention discloses an immune colloidal gold detecting card of carbendazin and a preparation method of the immune colloidal gold detecting card, and relates to the technical field of animal source food veterinary drug residue detection. A test strip in a shell of the detecting card is composed of a PVC glue plate, a sample cushion, a colloidal gold conjugate pad, a coating film and a water absorbing cushion, wherein a colloidal gold film is a glass cellulose membrane containing carbendazin monoclonal antibodies, the coating film is a nitrocellulose film and is provided with a line T and a line C, the line T is wrapped by carbendazin protein conjugates, and the line C is wrapped by goat-anti-mouse IgG antibodies. The detecting card can be effectively used for rapidly detecting carbendazin and is convenient to use, rapid and accurate in result.

Owner:NANJING YITE BIOTECH

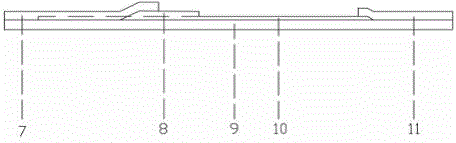

Carbendazim monoclonal antibody, preparation method and application thereof

InactiveCN102675463ASpecific bindingMeet dose dependenceMicroorganism based processesTissue cultureAntigenAscitic fluid

The invention discloses a carbendazim monoclonal antibody, a preparation method and an application thereof. The carbendazim monoclonal antibody is prepared by a mouse hybridoma cell strain MC-3 with a preservation number of CGMCC N0.4575 and the preparation method is as follows: (1) introducing ninth amino acid residue of carbendazim into one amino group to obtain the carbendazim modified by the amino and coupling the carbendazim modified by the amino with a carrier protein to obtain a complete antigen A; (2) immunizing a mouse by the complete antigen A obtained in step (1), taking splenocyteof the immune mice to fuse with a mouse myeloma cell to screen out a positive hybridoma cell strain; extensively culturing the positive hybridoma cell strain and injecting the positive cell strain into a homologous mouse abdominal cavity to induce to generate ascitic fluid and to obtain more carbendazim monoclonal antibodies. The Carbendazim monoclonal antibody can be used for detecting the carbendazim.

Owner:PEOPLES REPUBLIC OF CHINA BEIJING ENTRY EXIT INSPECTION & QUARANTINE BUREAU

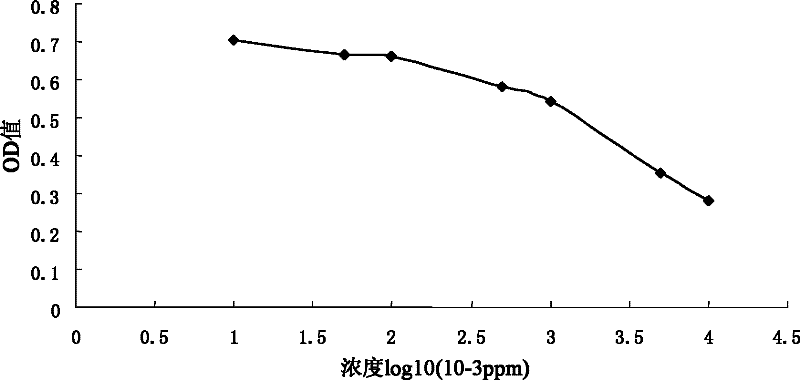

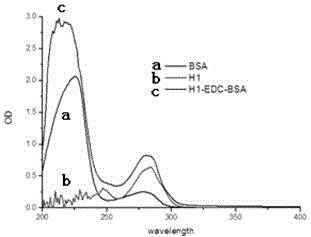

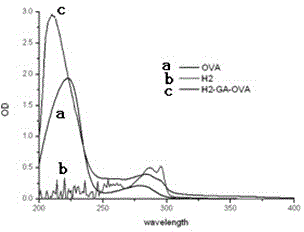

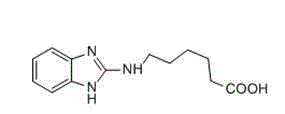

Synthesis method of high-sensitivity carbendazol complete antigen

ActiveCN104017070AStrong specificityHigh sensitivityOvalbuminSerum albuminHeterologousCarboxyl radical

The invention relates to a synthesis method of a high-sensitivity carbendazol complete antigen, belonging to the technical field of biochemical engineering. In the method, a carboxylic hapten H1 is synthesized by reacting carbendazol analog 2-chlorobenzimidazole and 6-aminocaproic acid, and is coupled with a carrier protein to prepare an immunogen; and on the basis that the heterologous coating can further enhance the sensitivity of the antibody, the hapten H2 obtained by reacting the carbendazol analog aminochlorobenzimidazole and 6-aminocaproic acid is coupled with OVA to obtain the coupled substance which can be used as a coating source. The complete antigen prepared by the method appears a specific carbendazol antigenic determinant, thereby providing possibilities for screening out high-specificity carbendazol monoclonal antibodies. The generated antibody has the advantages of high specificity and high sensitivity, and can be used for establishing an enzyme linked immunosorbent assay analysis method and a colloidal gold test paper quick detection method, thereby being used for quickly detecting carbendazol residues in food.

Owner:JIANGNAN UNIV

Seed coating agent containing benfuracarb

The invention relates to a seed coating agent which comprises benfuracarb of insecticide as an active componet and high polymers like polythene alcohol or polypropylene acidamide as film-builders. With additives said seed coating agent can be processed into water-emulsion, hung-emulsion and dry powered type; the seed coating agent can be fixed to be insecticide and bactericide combined seed coating agent with additional bactericides as thiram, tebuconazole, N-butyl pertluorooctane sulfonamide, metalaxyl, carbendazol, prochloraze or seedvax as second active component. Said seed coating agent is mainly used to prevent aphid of corn, soja, paddy or cotton and a plurality of underground pest; and the combined type can treat black silk disease, kernel smut, stem rot in seedling stage and anthrax.

Owner:ZHEJIANG HETIAN CHEM CO LTD

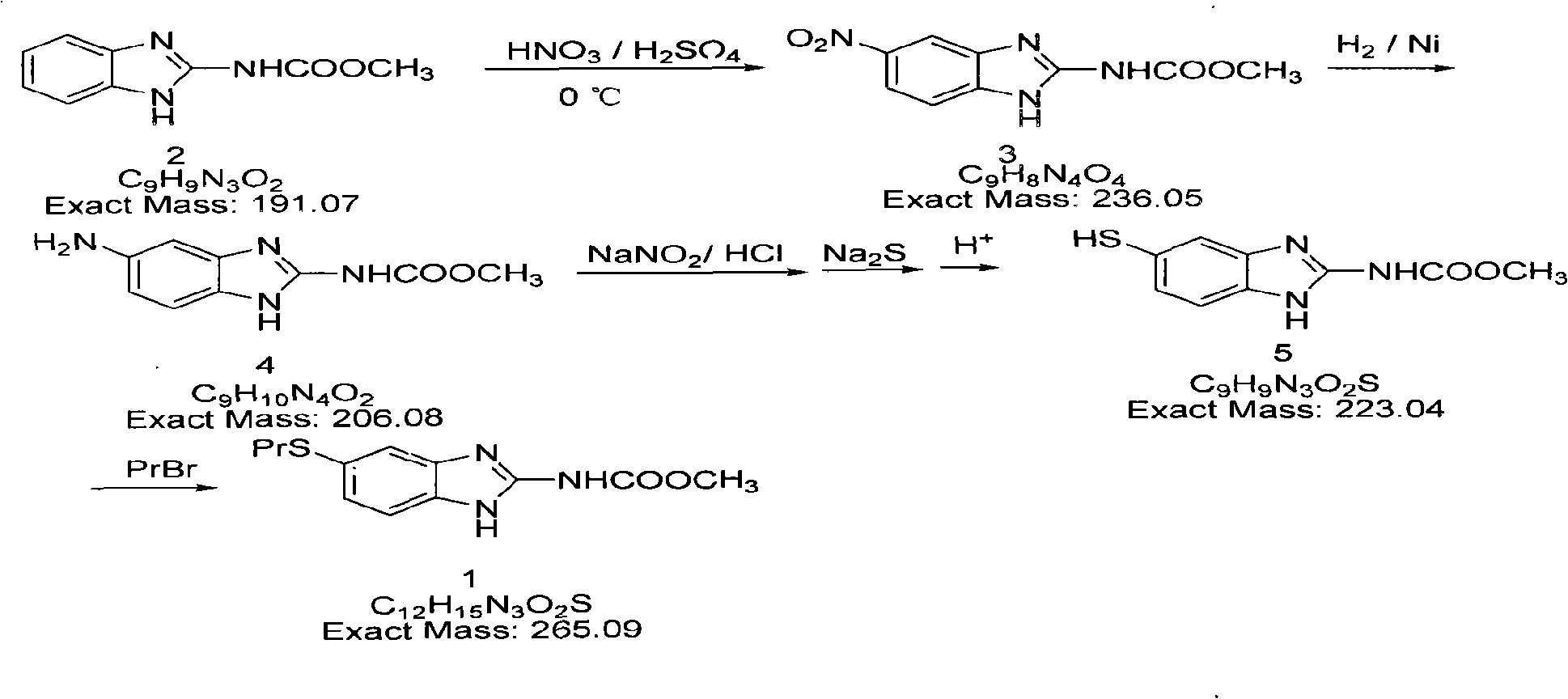

Method for synthesizing albendazole

The invention relates to a synthetic methodsynthesis method for albendazole, which is characterized in that benzimidazole -2 - methyl carbamate (carbendazim) is taken as raw material to generare 5-nitrobenzene and imidazole -2-methyl carbamate through nitration reaction, or generare 5- amino benzimidazole -2 - methyl carbamate through reduction reaction, or generate 5 - amino benzimidazole -2 - methyl carbamate through diazotization and substitution reaction, or generate albendazole through alkylation reaction. The method of the invention has simple and convenient synthetic route, mild conditions and high product quality, with the total yield reaching more than 58%.

Owner:徐州诺特化工有限公司

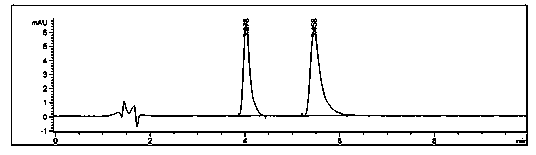

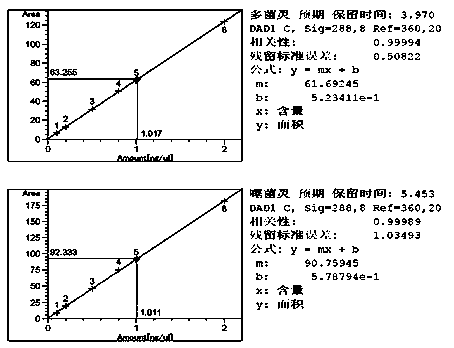

Method for detecting carbendazol and thiabendazole residues in fruit and vegetable juice through liquid chromatogram

The invention discloses a method for detecting carbendazol and thiabendazole residues in fruit and vegetable juice through liquid chromatogram, and belongs to the technical field of food safety detection. The method comprises the following steps: extracting the fruit and vegetable juice by virtue of a hydrochloric acid solution, purifying by a solid-phase extraction column, blowing with nitrogen to dry the purified product, making up to volume through the hydrochloric acid solution, and detecting through liquid chromatogram. Carbendazol and thiabendazole can be simultaneously detected through the method disclosed by the invention, the amount of the carbendazol and thiabendazole residues in the fruit and vegetable juice can be analyzed, the sample treatment is simple, the toxicity is small, and the recycling rate and the flexibility are high.

Owner:GUANGZHOU INST FOR FOOD INSPECTION(GUANGZHOU INSPECTION CENT FOR WINE & SPIRITS)

Multifunctional corn composite granules

InactiveCN101999401AThe test effect is goodGood effectBiocidePlant growth regulatorsBiotechnologyPhoxim

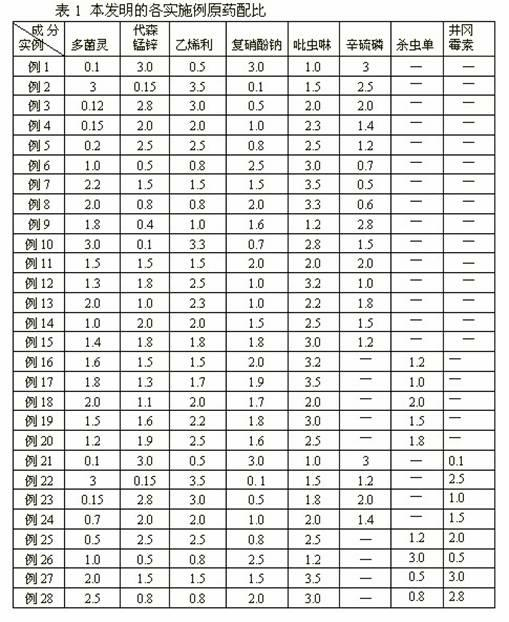

The invention relates to multifunctional corn composite granules, which comprise the following raw materials in percentage by weight: 0.1 to 3.0 percent of carbendazol, 0.1 to 3.0 percent of mancozeb, 0.5 to 3.5 percent of ethephon, 0.1 to 3.0 percent of compound sodium nitrophenolate, 1.0 to 3.5 percent of imidacloprid, 0.5 to 3.0 percent of phoxim or monosultap and the balance of auxiliary materials. Bactericide, pesticide and growth adjustor are compounded in the granules to integrate pest removal, pathogenic bacteria prevention and control and growth adjustment, and the granules are applied at one time and can simultaneously prevent and control multiple pests and pathogenic bacteria of corn; and the total prevention and control rate of the granules on the corn pests reaches over 90 percent, and the average yield increase range of the corn is 25 to 35 percent. the granules have broad spectrum, high efficiency, low toxicity, good compatibility, complementary effect and long acting time, can ensure that the corn is not harmed by the pests such as stem borers, aphids and the like during the whole corn growth period by early application, and thoroughly solve the problem of difficult prevention and control of plant diseases and insect pests in the medium and later stages of the corn growth.

Owner:段厚礼

Antibacterial Composition, Antibacterial Molding, Solution Containing Antibacterial Composition, Detergent, Surface of Tatami Mat and Tatami Mat

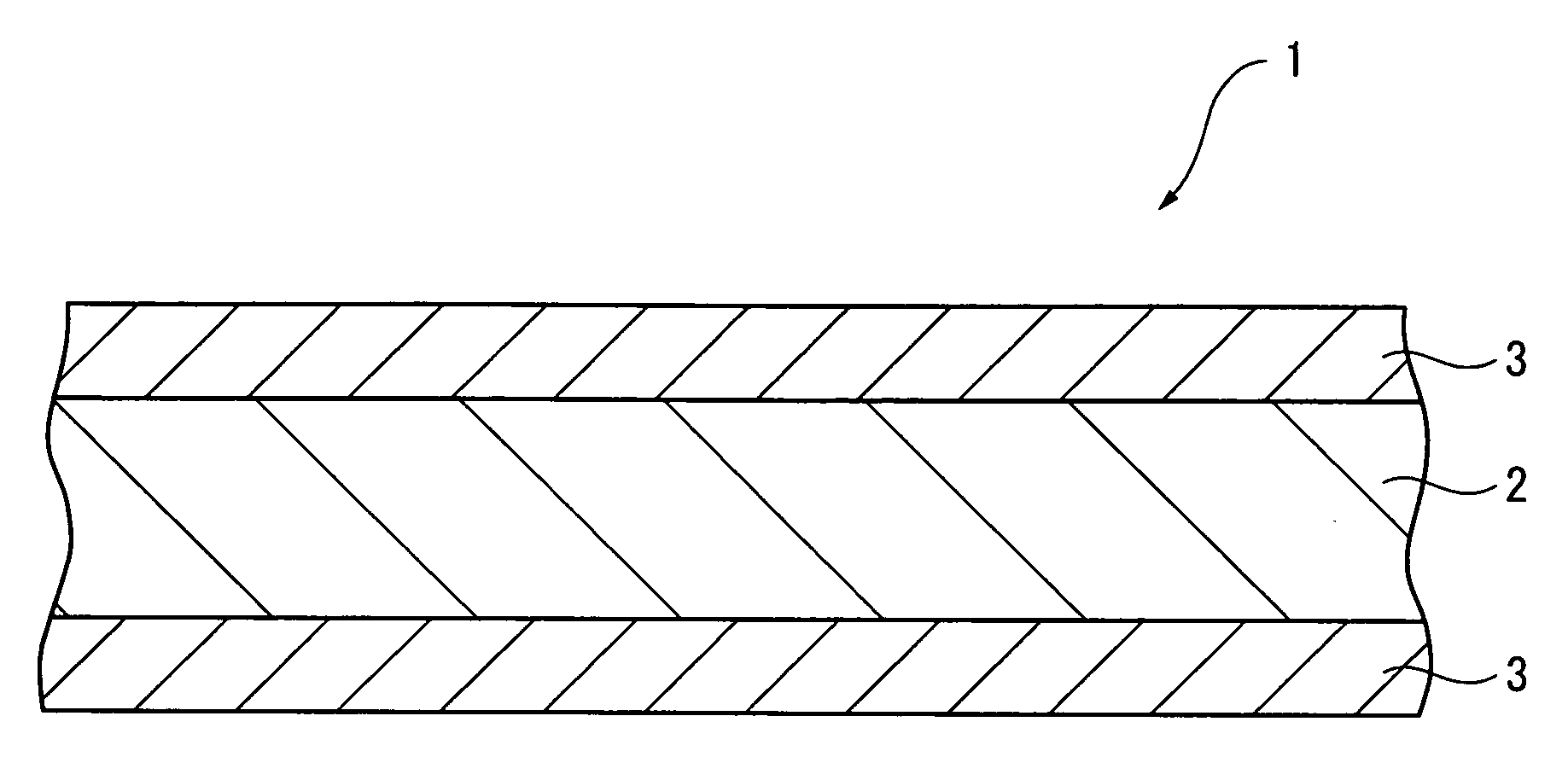

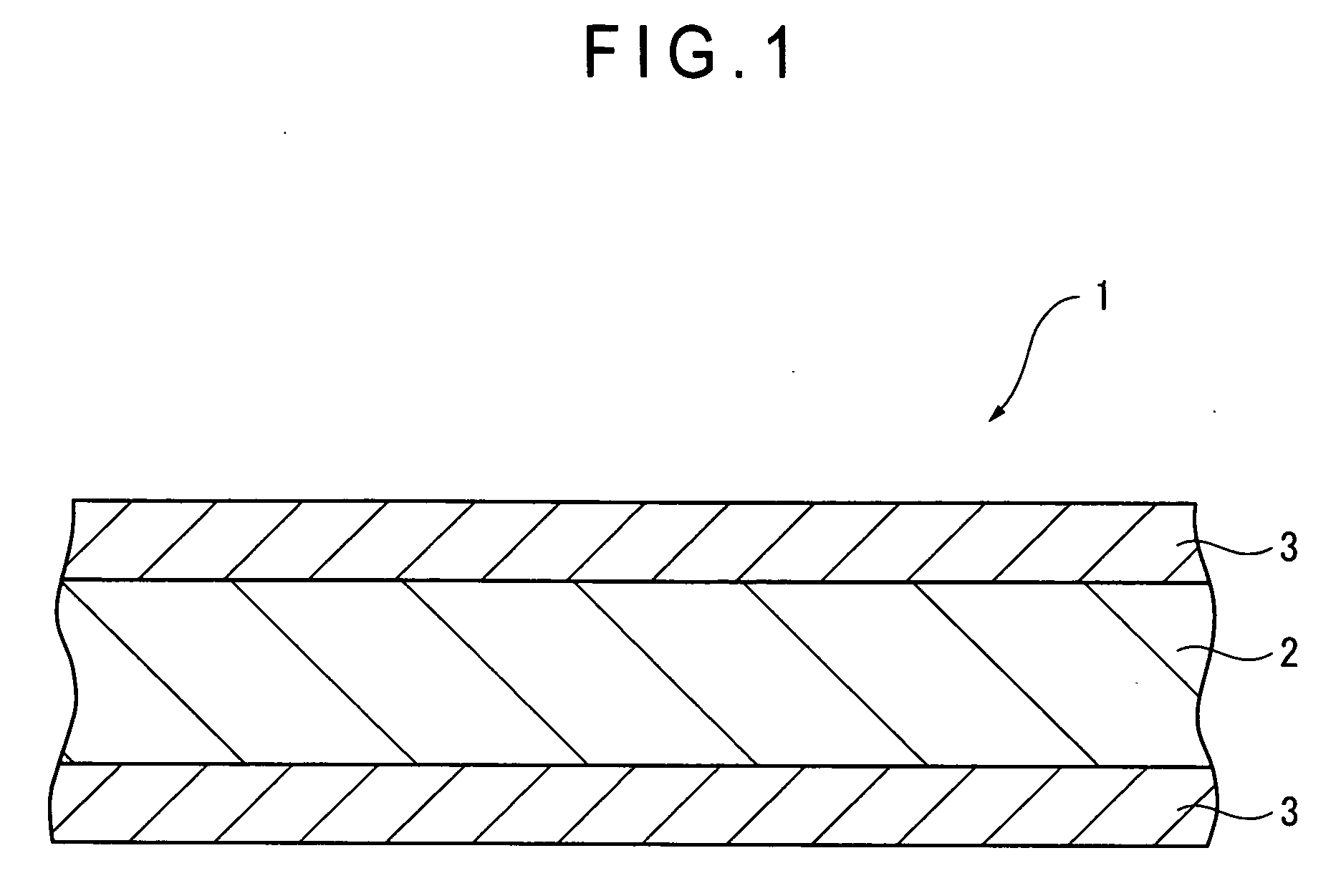

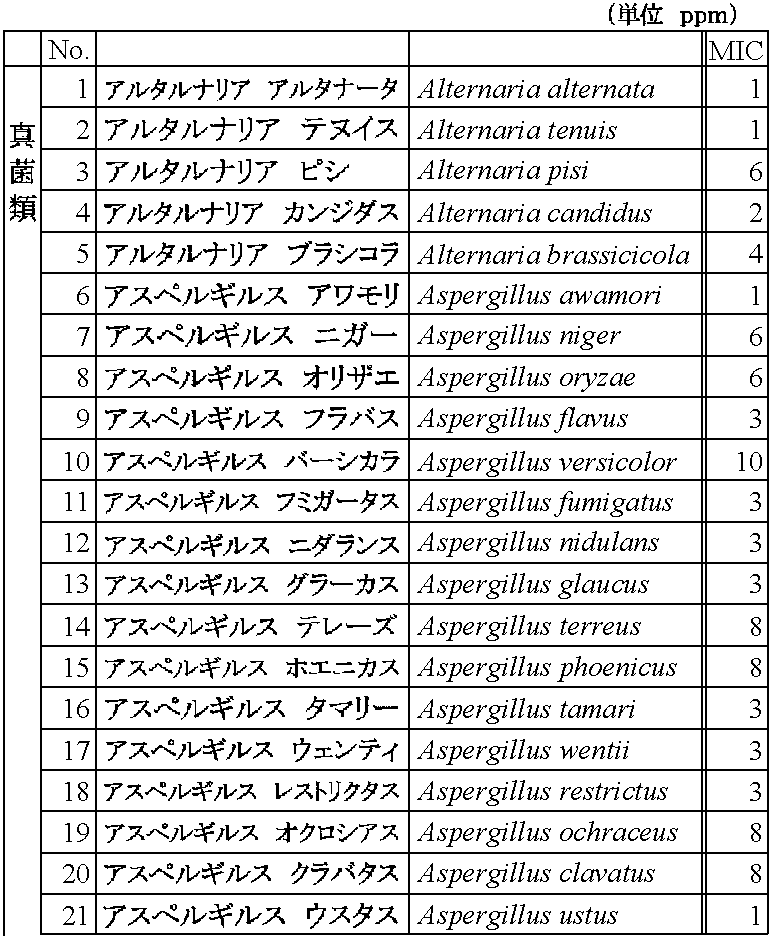

InactiveUS20080138385A1Provide propertyWell mixedInorganic/elemental detergent compounding agentsAntibacterial agentsPolymer scienceCarbamate

An antibacterial composition containing an organic antibacterial agent and an inorganic antibacterial agent is provided. Zirconium phosphate having supported thereon silver or copper or a salt thereof may be used as the inorganic antibacterial agent, and 2-mercaptopyridine-N-oxide sodium, carbendazim (methyl 1H-2-benzimidazole carbamate), or thiabendazole (2-(4-thiazolyl)-1H-benzimidazole) may be used as the organic antibacterial agent. Those components contain no halogen, so the antibacterial composition can be made halogen-free. The antibacterial composition may be applied to form an antibacterial molding, for example, by molding it together with a resin material or applying it together with a coating agent on a resin molding.

Owner:IDEMITSU TECHNOFINE CO LTD

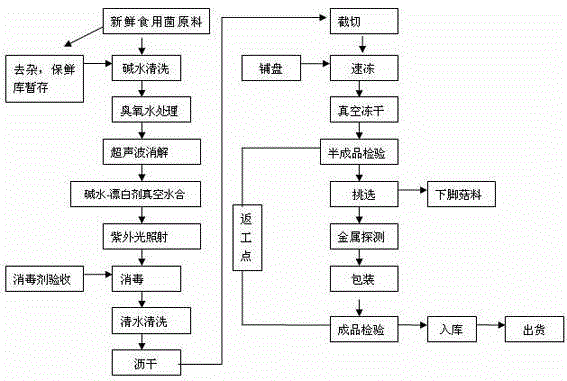

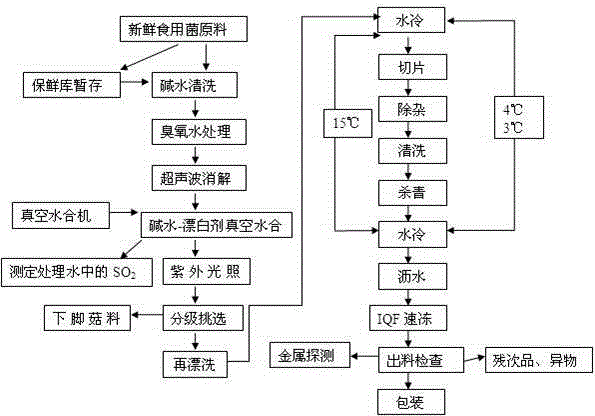

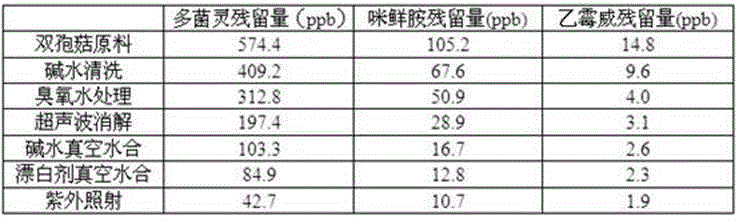

Production technique capable of lowering misole pesticide residues in edible fungus vacuum freeze-dried food

ActiveCN103907799ASolve the slow dissolution of residualSolve problems such as time-consumingFood preparationBiotechnologyAlkaline water

The invention relates to the technical field of safety and a processing technique of an edible fungus food, particularly a production technique capable of lowering misole pesticide residues in an edible fungus vacuum freeze-dried food. The process and technological parameters of the production technique of the traditional edible fungus vacuum freeze-dried food are reasonably improved. The production technique comprises the following steps: alkaline water cleaning on the edible fungus raw material, ozone water atomization, ultrasonic digestion, vacuum alkaline water-bleacher hydration and ultraviolet irradiation, thereby producing the edible fungus quick-frozen product of which the carbendazol and other misole pesticide residues conform to the national and international standards. The production technique provided by the invention effectively lowers the residues of the pesticide residues in the tin, enables the misole pesticides to conform to the international standard, and promotes the sustainable and healthy development of edible fungus industry.

Owner:FUZHOU UNIV

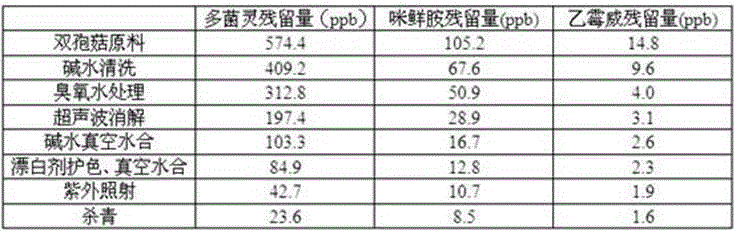

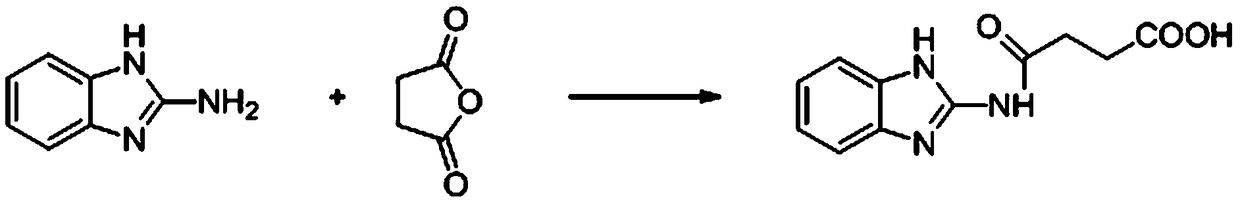

Preparation method and application of carbendazim hapten and antigen

InactiveCN109265404AQuick checkRetain chemical structureOvalbuminSerum albuminEpitope2-aminobenzimidazole

The invention discloses a preparation method and application of a carbendazim hapten and antigen. The method is characterized in that the carbendazim hapten is prepared from 2-aminobenzimidazole and butanedioic anhydride which are reacted; the carbendazim antigen is obtained by coupling the carbendazim hapten and carrier protein. The antigen prepared through the method presents a specific carbendazim antigenic determinantantigen epitope, so that screening out a high-specificity carbendazim monoclonal antibody becomes possible; the generated antibody is high in specificity and high in sensitivity, and can be used for building an enzyme-linked immunosorbent assay method and a colloidal gold test strip rapid determination method, so that carbendazim in tobacco and food is fast detected.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +2

Agricultural bactericidal composition

The invention relates to a bactericidal composition comprising the effective components of (A) and (B), wherein the (A) is ethirimol or bupirimate, the (B) is one of sanmate, benomyl, thiophanate-methyl or thiabendazole, and the mass proportion of the A to the B is 50:1-1:50. The composition has an obvious synergistic action and can be used for preventing and treating diseases on crops, such as fruit trees, cotton, paddy, wheat, vegetables and the like, especially for preventing and treating fungoid diseases.

Owner:SHENZHEN NOPOSION AGROCHEM

Production technique capable of lowering misole pesticide residues in edible fungus quick-frozen food

ActiveCN103907800ASolve the slow dissolution of residualSolve problems such as time-consumingFood ingredient functionsFood ultrasonic treatmentBiotechnologyAlkaline water

The invention relates to the technical field of safety and a processing technique of an edible fungus food, particularly a production technique capable of lowering misole pesticide residues in an edible fungus quick-frozen food. The process and technological parameters of the production technique of the traditional edible fungus quick-frozen food are reasonably improved. The production technique comprises the following steps: alkaline water cleaning on the edible fungus raw material, ozone water atomization, ultrasonic digestion, vacuum alkaline water-bleacher hydration and ultraviolet irradiation, thereby producing the edible fungus quick-frozen product of which the carbendazol and other misole pesticide residues conform to the national and international standards. The production technique provided by the invention effectively lowers the residues of the pesticide residues in the tin, enables the misole pesticides to conform to the international standard, and promotes the sustainable and healthy development of edible fungus industry.

Owner:FUZHOU UNIV

Method for synthesizing albendazole

The invention relates to a method for synthesizing albendazole. The method comprises the following steps of: (a) adding carbendazim, sodium sulfocyanate and glacial acetic acid to a reactor, dropwise adding 28% hydrogen peroxide while controlling the temperature to be 25-40 DEG C, carrying out heat preservation and reaction for 4-6 hours after the dropwise adding process is completed, and obtaining thiocyanide after glacial acetic acid is recovered through negative-pressure distillation; and (b) adding 20% aqueous potassium hydroxide solution to the thiocyanide while adding benzyltriethylammonium chloride, then dropwise adding 1-bromopropane, and reacting for 4-8 hours while controlling the temperature to be 45-60 DEG C, thereby obtaining the albendazole. According to the method, the potential safety hazard caused by the fact that a highly toxic substance, namely chlorine gas, is used for preparing albendazole is avoided successfully, and the influence on the quality and yield of the product, caused by side reactions resulting from the adoption of the chlorine gas, is eliminated successfully, so that the quality and yield of an intermediate are improved greatly; meanwhile, the adoption of alkali sulfide is cancelled, and then, the environmental pollution caused by a byproduct, namely thioether, produced due to excessive alkali sulfide is avoided, so that the method is perfectly suitable for industrial production; and furthermore, all the raw materials are low in cost and are purchased easily, and the operation is safe.

Owner:苏州诚和医药化学有限公司

Preservation method for bamboo shoot

InactiveCN106720275APrevent dehydrationInhibit lignificationFruits/vegetable preservation by freezing/coolingCold storageChemistry

The invention provides a preservation method for a bamboo shoot. The preservation method comprises the following steps: cleaning and trimming a fresh bamboo shoot, wherein the cleaning and trimming refer to gently wiping off soil on the sheath of the bamboo shoot with fingers and cutting off inedible parts using a knife; immersing the root of the bamboo shoot into a preservative solution for 5-10 minutes, wherein the preservation solution is a mixed solution of carbendazol and sodium propionate, and placing the treated bamboo shoot in air for airing; employing a container of which the bottom is fully paved with sandy soil, vertically placing the dry bamboo shoot in the container, burying the bamboo shoot with the sandy soil, keeping the humidity to be 8-10%, and finally, covering the container with a polyethylene plastic bag, and then placing the container in refrigeration house for storage. According to the preservation method, the compound preservative is combined with preservation in sandy soil to effectively inhibit the lignifying and browning degree of the bamboo shoot, and therefore, the consumption of the nutritional quality is reduced; the maintenance of the quality of the bamboo shoot is facilitated; and the storage period of the bamboo shoot is prolonged.

Owner:SHANGHAI INST OF TECH

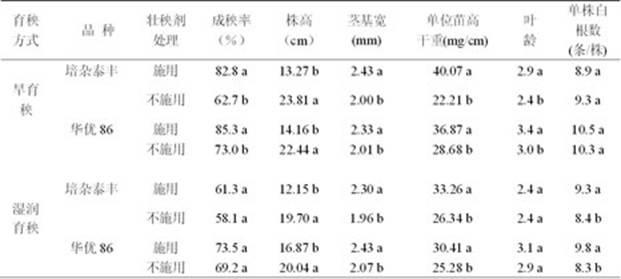

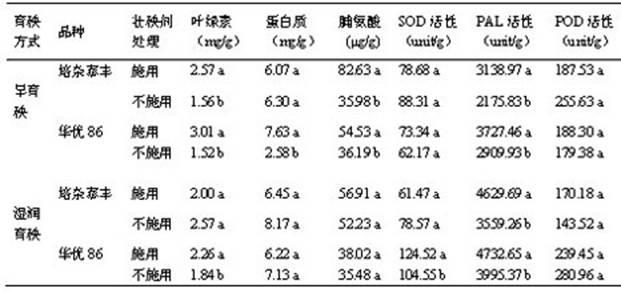

Seedling-strengthening agent special for super rice and using method thereof

The invention discloses a seedling-strengthening agent special for super rice and a using method thereof. The seedling-strengthening agent special for the super rice consists of the following components in part by weight: 50 parts of ammonium sulfate, 10 parts of superphosphate, 19.6 parts of potassium chloride, 20 parts of biological organic fertilizer, 0.2 part of paclobutrazol and 0.2 part of carbendazim. The seedling-strengthening agent can obviously improve the leaf emergence rate of seedlings, reduce the plant height, increase the stem base width, the biomass and the chlorophyll contentof the seedlings, obviously improve the protein and proline content of the seedlings, and enhance the activity of phenylalanine ammonia-lyase so as to improve the stress tolerance of the seedlings and fulfill the aim of culturing strong seedlings.

Owner:SOUTH CHINA AGRI UNIV

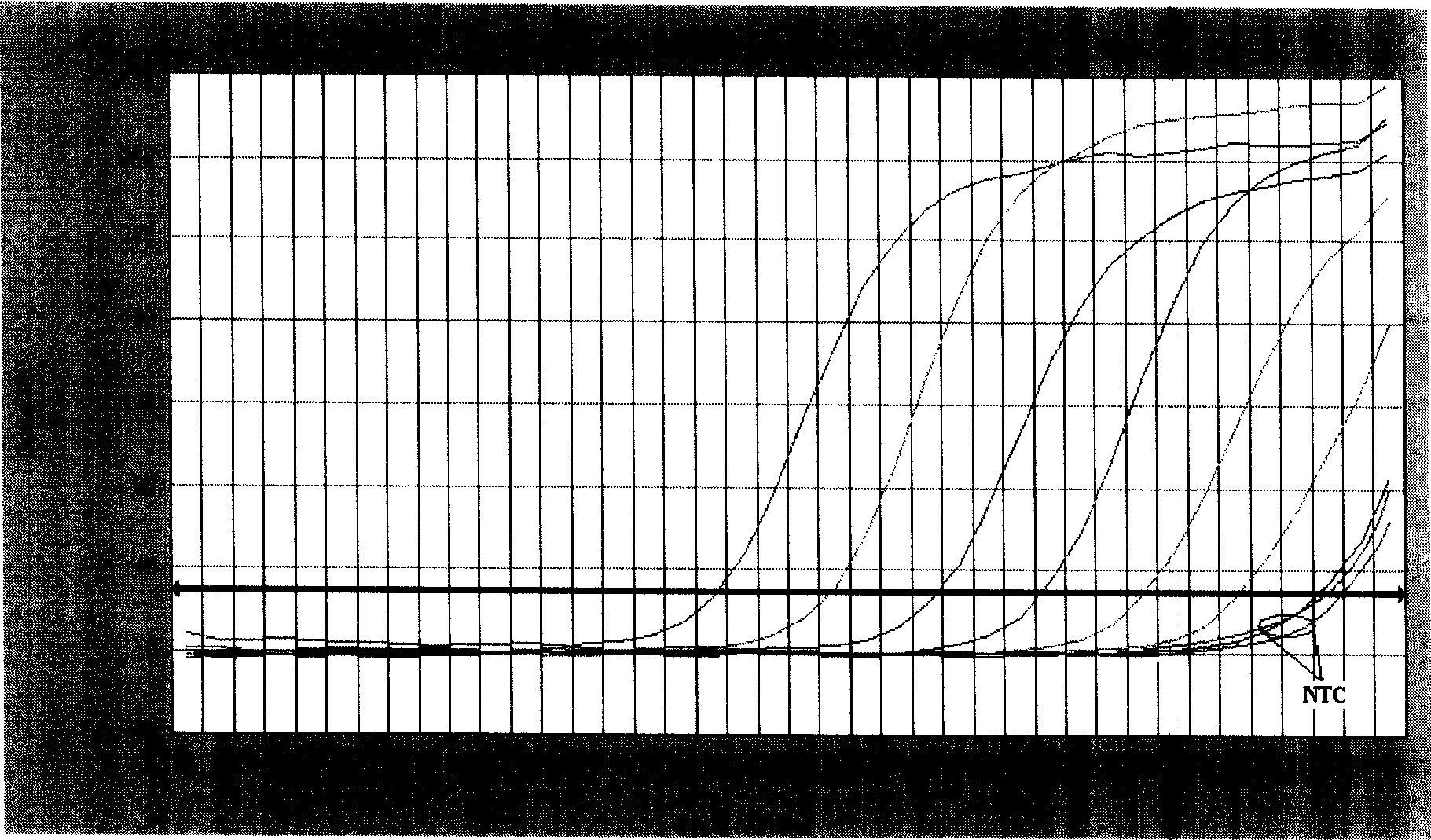

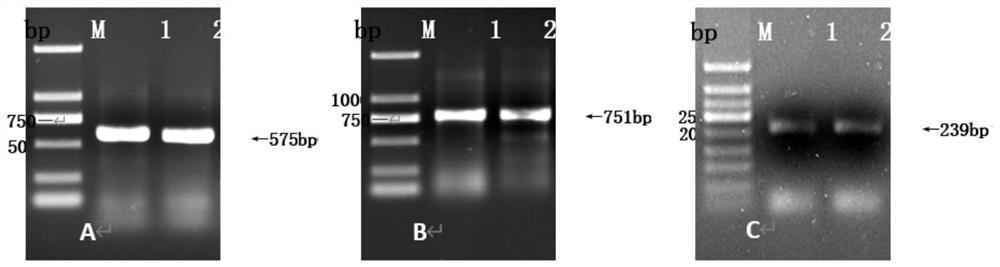

High throughput real-time detection technology for drug resistance gene frequency of Sclerotinia sclerotiorum population

InactiveCN101475982AHigh specificityHigh amplification efficiencyMicrobiological testing/measurementPathogenPopulation

The present invention belongs to a real-time detection method of the frequency of drug resistance genes in Sclerotinia sclerotiorum syngen, which can be used for drug resistance monitoring and popularity warning of carbendazim and other benzimidazole fungicide resistance in sclerotinia sclerotium disease of cole and the like crops. The detection method is divided into three major steps, the first step: respectively extracting the nuclear genome DNA of known drug-resistant strains, sensitive strains and sample to be measured; the second step: using the specific detection primers of drug-resistant strains and Sclerotinia sclerotiorum strains for real-time quantitative PCR reactions, respectively establishing the standard curves of the drug-resistant strains and Sclerotinia sclerotiorum strains detection; the third step: sample to be measured respectively using the two specific primers for real-time quantitative PCR reactions, contradistinguishing with the established standard curves, obtaining the corresponding numbers of the drug-resistant strains and sensitive strains and the proportion of the drug-resistant strains in the total number of the Sclerotinia sclerotiorum. The use of real-time quantitative PCR technology can perform high-throughput, rapid and accurate quantitative detection of the number of field drug-resistant Sclerotinia sclerotiorum and its proportion in the pathogen syngens, which has high-throughput characteristic. Compared with the conventional biometrics and general PCR detection of drug-resistant strains, the invention is time-saving, cost-saving and fast. The whole process from directly extracting the genome DNA from the sclerotia, disease spots and spores collected to real-time quantitative-PCR detection is only 6h needed, and the detection accuracy rate is more than 96%.

Owner:NANJING AGRICULTURAL UNIVERSITY

Pesticide composition containing penthiopyrad

The invention discloses a pesticide composition containing penthiopyrad, which contains an active component A and an active component B, wherein the active component A is penthiopyrad; the active component B is selected from any one of polyoxin, phosethyl-Al, thiophanate-methyl, carbendazol, dithianon and triflumizole; and the weight ratio of the active component A to the active component B is 1:80-60:1. The composition disclosed by the invention has higher activity for multiple diseases on multiple crops, and has obvious synergistic action, thereby widening the bactericidal spectrum. The composition has the characteristics of small dosage, rainfall erosion resistance and obvious synergistic action.

Owner:SHAANXI MEIBANG PHARMA GRP CO LTD

Composition containing tebuconazole, prochloraz and cartap and application of composition

InactiveCN104273155AOvercoming the hazards of drug resistanceSynergistic effect is obviousBiocideFungicidesBiologyCarbendazim

The invention discloses a composition containing tebuconazole, prochloraz and cartap and application of the composition. The composition comprises active ingredients and auxiliary materials, wherein the active ingredients comprise tebuconazole, prochloraz and cartap in a weight ratio of (0.5-10) to (0.5-2) to (0.5-2). The composition is capable of effectively overcoming the pesticide resistance hazards of fusarium moniforme to carbendazim and prochloraz and is capable of controlling rice crimp nematode; meanwhile, tebuconazole and prochloraz have a remarkable synergistic effect after being compounded.

Owner:JIANGSU LVDUN PLANT PROTECTION AGROCHEM EXPERIMENTAL

Bactericidal composition containing coumoxystrobin and benzimidazole bactericide

ActiveCN102349531AImprove securityGood control effectBiocideFungicidesWater dispersibleBULK ACTIVE INGREDIENT

The invention discloses a bactericidal composition containing coumoxystrobin and benzimidazole bactericide. The bactericidal composition comprises the coumoxystrobin serving as an active ingredient and the benzimidazole bactericide selected from thiophanatemethyl, carbendazol or benomyl; and the weight ratio of the coumoxystrobin to the benzimidazole bactericide is 1:1-1:50. The composition can be prepared into agriculturally allowable water dispersible granules, wettable powder or suspension. The composition has reasonable components, good bactericidal effect and low application cost, and the activity and the bactericidal effect of the composition are not simply superposed activity and bactericidal effect of the components; compared with the conventional single preparation, the composition has the advantages of remarkable bactericidal effect, remarkable synergy, retarded resistance, low preparation residue, no pollution to crops, good safety and accordance with the safety requirement of the pesticide preparation; and the composition has remarkable effect of preventing and controlling apple ring rot, anthracnose, rot, rice sheath blight, rice blast and wheat scab.

Owner:SHAANXI SUNGER ROAD BIO SCI

Ipconazole-containing bactericidal composition

The invention discloses an ipconazole-containing bactericidal composition. The bactericidal composition comprises an active ingredient A and an active ingredient B, wherein the active ingredient A is ipconazole; the active ingredient B is one selected from carbendazim, thiophanate methyl, probenazole, prochloraz, imazalil and triflumizole; the weight percentage ratio of the active ingredient A to the active ingredient B is (1-40):(1-80); and auxiliary agents and excipients are added into the active ingredients to prepare wettable powder, water dispersible granules, suspensions or suspoemulsion. The bactericidal composition is used for preventing and controlling rice blast, bakanae disease, leaf mold, cladosporium cucumerinum, ring spot, alternaria leaf spot, anthracnose, spot anthracnose and powdery mildew, is resistant to rain wash and has an obvious synergistic effect.

Owner:SHAANXI MEIBANG PHARMA GRP CO LTD

Composite pesticide containing ethylicin and tebuconazole, and application thereof

ActiveCN104222102AOvercoming the hazards of drug resistanceSynergistic effect is obviousBiocideFungicidesActive componentProchloraz

The invention discloses a composite pesticide containing ethylicin and tebuconazole, and application thereof. The composite pesticide contains active components and auxiliary materials, wherein the active components comprise the ethylicin and the tebuconazole, and the weight ratio of the ethylicin to the tebuconazole is (1-6):(0.5-10). The composite pesticide disclosed by the invention can effectively overcome the drug-resistant harm of fussrium moniliforme to badistan and prochloraz, and the tebuconazole and the ethylicin are compounded, so that the composite pesticide has an obvious synergistic effect.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

Preparation method of cottonseed bactericidal hybridization solution containing sodium dichloro cyanurate and hymexazol

The invention relates to a preparation method of a hybridization solution for agricultural prevention and treatment, in particular relates to a preparation method of a cottonseed bactericidal hybridization solution containing sodium dichloro cyanurate and hymexazol, and the preparation method is used for solving the existing problems of poor emergence rate and environment pollution which are caused by the adoption of carbendazim for prevention and treatment after the cottonseeds are sown. The preparation method provided by the invention comprises the following steps: a, selecting the following raw materials in parts by weight: 6 to 8 parts of sodium dichloro cyanurate and 2 to 4 parts of hymexazol, and mixing the raw materials; b, diluting a mixture to form a solution which is 250 or 500 times greater than the mixture, thereby preparing the hybridization solution. The prepared hybridization solution is wide in bactericidal spectrum and obvious in prevention and treatment effect, and is capable of delaying the occurrence of diseases and effectively guaranteeing the safety of crops and environments and can play a synergic role on plant growth at the same time so as to reduce the drug application cost of peasants.

Owner:COTTON RES INST SHANXI ACAD OF AGRI SCI

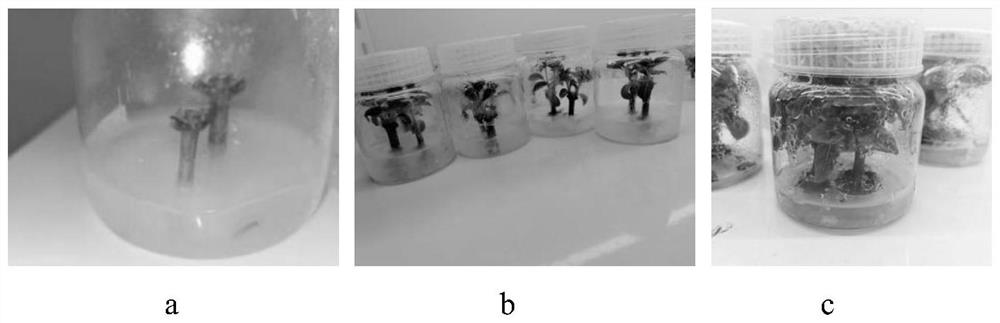

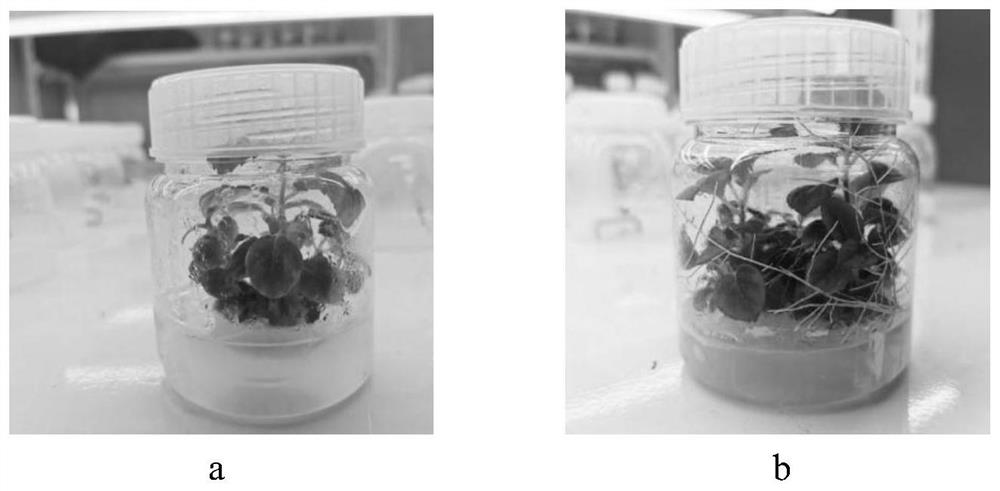

In vitro shoot culturing method of hydrangea paniculata

ActiveCN111727884AReduce browning rateLow pollution rateHorticulture methodsPlant tissue cultureBiotechnologyShoot

The invention discloses an in vitro shoot culturing method of hydrangea paniculata. The in vitro shoot culturing method comprises the steps of collecting explants; soaking the explants in washing powder, performing flushing with running water, performing soaking in mixed liquid of carbendazol and streptomycin, performing flushing with bacteria-free water, and then performing surface disinfection:performing soaking in 75% alcohol, performing flushing with the bacteria-free water, performing soaking in an HgCl2 solution and performing flushing with the bacteria-free water; trimming cutouts in two ends of each explant which is sterilized and disinfected, performing cutting to obtain stems with buds, and vertically inoculating the stems with buds in a starting culture medium; cutting tissue culture seedlings subjected to starting culture to obtain stems with buds, cutting off leaves which can be in contact with the culture medium, and perpendicularly inoculating the stems in a propagationculture medium; and performing propagation culture, then trimming basal parts of the tissue culture seedlings, transferring the trimmed tissue culture seedlings to a rooting culture medium, and inducing roots. The method is good in starting effects and low in browning rate and pollution rate, the browning rate is 0, the pollution rate is as low as 5%, the germination induction rate and the propagation coefficient are high, the fermination rate is 100%, the proliferation coefficient is as high as 7, the rooted seedlings are strong, the rooting rate is 100%, the average root quantity is 22, andthe average root length is 3.10cm.

Owner:JIANGSU POLYTECHNIC COLLEGE OF AGRI & FORESTRY

Disposable trace carbendazim silk-screen printing electrochemical sensor

ActiveCN105044193AIncreased sensitivityHigh sensitivityMaterial electrochemical variablesIonElectrochemistry

The present invention relates to the technical field of electrochemical sensors, particularly to a disposable trace carbendazim silk-screen printing electrochemical sensor. According to the present invention, the graphene oxide electrode is modified with the ionic liquid, such that the sensitivity of the disposable trace carbendazim silk-screen printing electrochemical sensor is excellent so as to improve the accuracy of the detection on the substance to be detected and especially improve the sensitivity of the sensor on the carbendazim, such that the detection accuracy on the carbendazim is improved.

Owner:ZUNYI NORMAL COLLEGE

Transplanting transition method of insectivorous plant tissue culture seedlings

ActiveCN111011190AShortened growth periodHigh transplant survival rateGrowth substratesCulture mediaThiophanate-methylCarbendazole

The invention relates to a transplanting transition method of insectivorous plant tissue culture seedlings, and belongs to the technical field of transplanting of insectivorous plant cultured seedlings. The insectivorous plant tissue culture seedlings are used as transplanting targets, transplanting is performed in the following manner of flushing roots of rooting seedlings, performing soaking with 1000-1250ppm thiophanate methyl or carbendazol for 10-15min, selecting a mixture of perlite and turf in the volume ratio being (1.5-2) to 1 as cultivation substrates, performing cultivation under the condition of light shading being 78-80% for 15-20 days, performing cultivation under the condition of light shading being 30-40% for 15-20 days, performing full-light cultivation for 10 days, and counting survival rate. According to the transplanting transition method disclosed by the invention, seedling hardening is not needed for transplanting, and after culture mediums are thoroughly cleaned,transplanting is directly performed; besides, through control and management in a transplanting process, higher transplanting survival rate can be achieved; and besides, in the transplanting process,a management manner is simple, too much time and too many human resources do not need to be consumed, and the growth period of insectivorous plants can be shortened.

Owner:FLOWER RES INST OF YUNNAN ACAD OF AGRI SCI

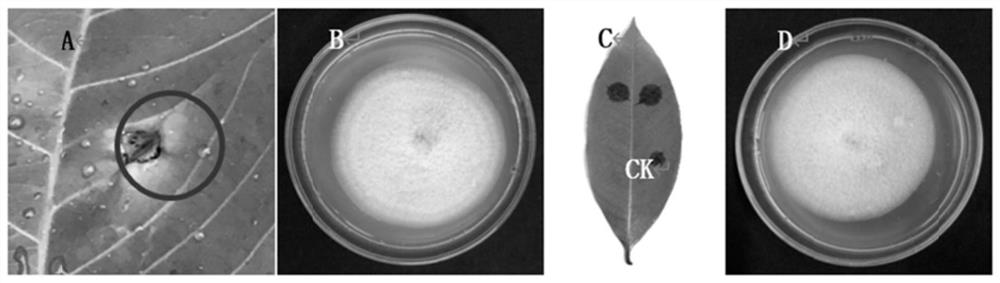

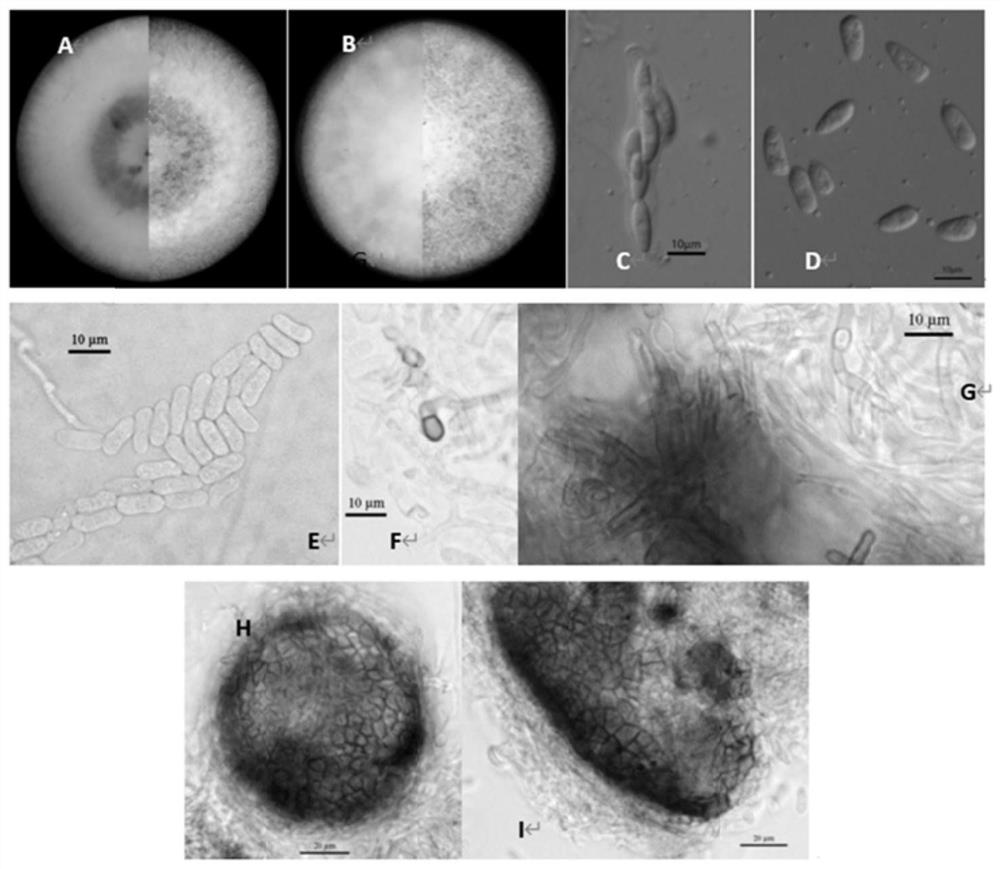

Rubber tree colletotrichum drug-resistant strain HcgHNQZ1736 and application thereof in drug resistance research

The invention belongs to the technical field of plant genetic engineering, and particularly relates to karst colletotrichum and application thereof in the field of rubber anthracnose research. The karst colletotrichum is found on rubber trees in Hainan Province for the first time; and a strain obtained through separation is C.karstii. Biological characteristic determination finds that the optimumgrowth temperature of the strain is 28 DEG C; the lethal temperature is 35 DEG C; the optimum growth pH is 6; light and dark alternation is beneficial to colony growth; and pectin and peptone are respectively an optimal carbon source and an optimal nitrogen source. Pathogenicity evaluation finds that the strain has relatively strong pathogenicity on four main recommended varieties including PR107,RRIM600, hot research 7-33-97 and Dafeng 95; a drug resistance evaluation result shows that the strain HcgHNQZ1736 has no drug resistance to a sterol demethylation inhibitor (DMIs) bactericide prochloraz-manganese chloride complex, and has high drug resistance to a benzimidazole bactericide carbendazim.

Owner:ENVIRONMENT & PLANT PROTECTION INST CHINESE ACADEMY OF TROPICAL AGRI SCI

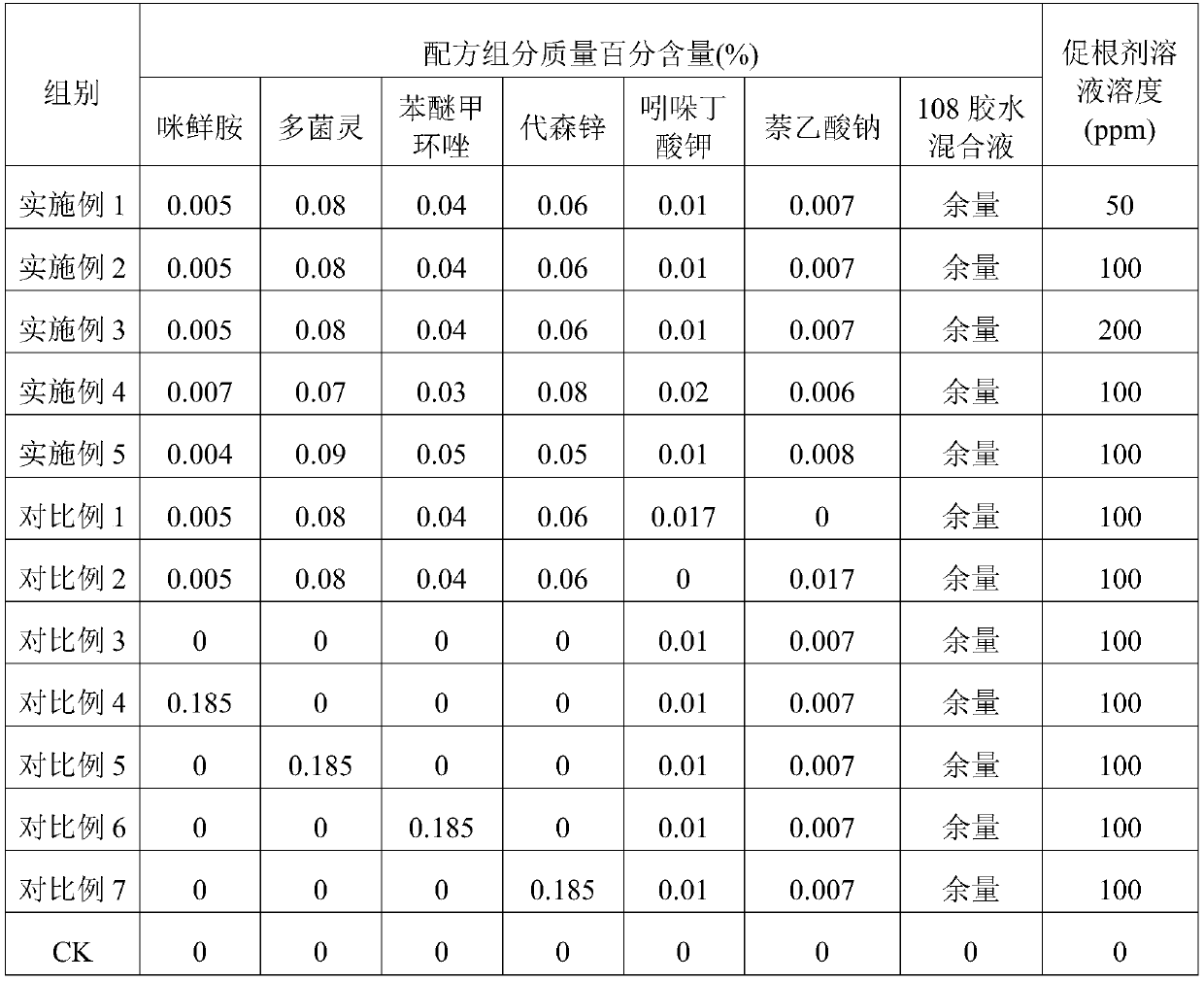

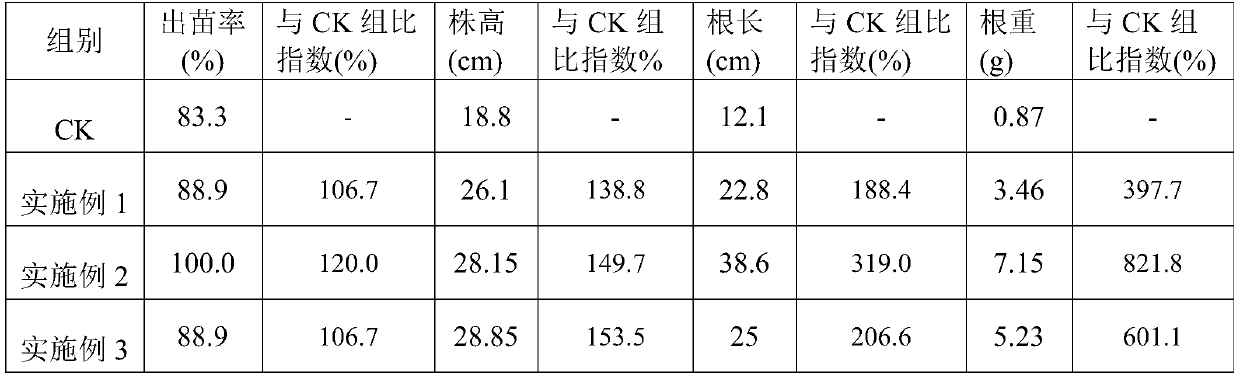

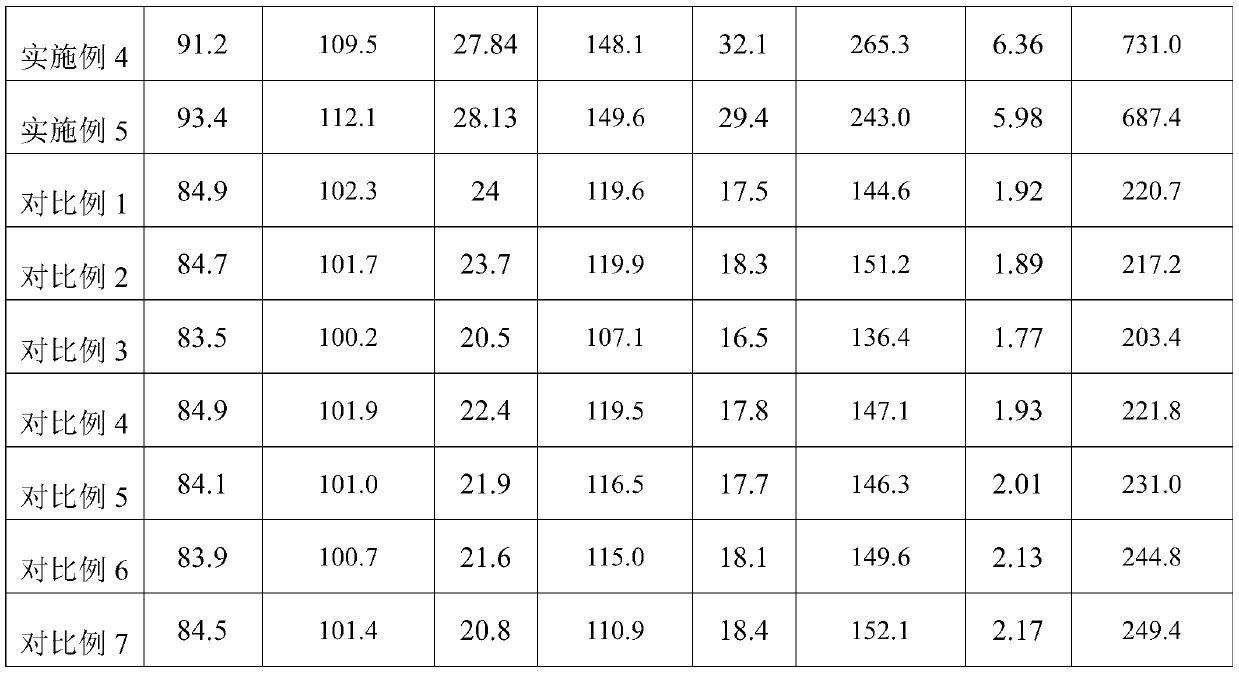

Sugarcane single-bud root growth promoting agent, and preparation method and application thereof

ActiveCN111213667ARoot promoting effect is obviousPromote growthPlant growth regulatorsBiocidePlant rootsRoot weight

The invention relates to the field of plant root growth promoters, and concretely discloses a sugarcane single-bud root growth promoting agent. The root growth promoting agent is prepared from, by mass, 0.004-0.007% of prochloraz, 0.07-0.09% of carbendazim, 0.03-0.05% of difenoconazole, 0.05-0.08% of zineb, 0.01-0.02% of indole-3-butyric acid potassium salt, 0.006-0.008% of pimacol, and the balance of a 108 glue mixed liquid. The root growth promoting agent induces the formation of a root source body and promotes the growth of roots; and all the components are matched with one another and acttogether to achieve a remarkable root promoting effect. The root growth promoting agent solution treatment can significantly improve the root length and root weight of sugarcane, increase the emergence rate and tillering rate of sugarcane, improve the stress resistance of sugarcane to a certain extent, and significantly increase the yield of sugarcane.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com