Production technique capable of lowering misole pesticide residues in edible fungus vacuum freeze-dried food

A technology of vacuum freeze-drying and pesticide residues, which is applied in food preparation, application, food science, etc., to achieve the effects of slow dissolution, simple production process, and reduced residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

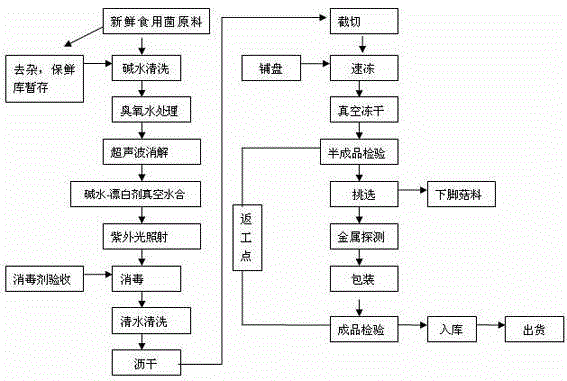

Method used

Image

Examples

Embodiment 1

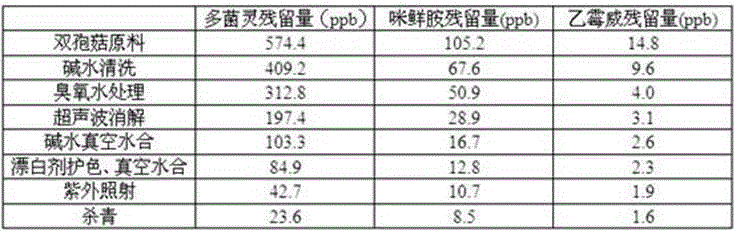

[0029] A production process for reducing imidazole pesticide residues in vacuum freeze-dried food of Agaricus bisporus, comprising the following steps:

[0030] (1) Agaricus bisporus acceptance, sampling inspection and acceptance, the qualified product rate is required to be more than 95%;

[0031] (2) Alkaline water cleaning: use sodium bicarbonate alkaline water with a concentration of 5wt%, and continuously wash Agaricus bisporus in the flow cell for 2 times; rinse with clean water for 2 times after cleaning; water cooling, the first water 15°C, time 2min; The second water 4 ℃, time 5min;

[0032] (3) Ozone water treatment: spread the cleaned raw materials of Agaricus bisporus into a pile with a thickness of 1~2cm, atomize the ozone water with a concentration of 5 mg / L, and evenly spray it on the Agaricus bisporus. 1%;

[0033] (4) Ultrasonic digestion: using frequency 20kHz, power 90w / cm 2 Ultrasonic digestion of Agaricus bisporus, ultrasonic for 2 hours;

[0034] (5) ...

Embodiment 2

[0043] A production process for reducing imidazole pesticide residues in mushroom vacuum freeze-dried food, comprising the following steps:

[0044] (1) Acceptance of shiitake mushrooms, sampling inspection and acceptance, the qualified product rate is required to be more than 95%;

[0045] (2) Alkaline water cleaning: use sodium hydroxide alkaline water with a concentration of 2wt%, wash the shiitake mushrooms in the flow cell continuously for 3 times; rinse with clean water for 2 times after cleaning; water cooling, the first water 15 ℃, time 2min; The second water 4 ℃, time 5min;

[0046] (3) Ozone water treatment: spread the washed shiitake mushrooms into a pile of 1~2cm thick, atomize the ozone water with a concentration of 10mg / L, and spray evenly on the shiitake mushrooms. The amount of ozone water is 0.5% of the weight of the shiitake mushrooms. %;

[0047] (4) Ultrasonic digestion: using frequency 25kHz, power 75w / cm 2 Ultrasonic digestion of shiitake mushrooms by ...

Embodiment 3

[0053] A production process for reducing imidazolic pesticide residues in high-temperature mushroom vacuum freeze-dried food, comprising the following steps:

[0054] (1) Acceptance of high-temperature mushrooms, sampling inspection and acceptance, the qualified product rate is required to be more than 95%;

[0055] (2) Alkaline water cleaning: use potassium hydroxide alkaline water with a concentration of 3wt%, and continuously wash the high-temperature mushrooms in the flow cell for 3 times; rinse with clean water for 2 times after cleaning; water cooling, the first water 15°C, time 2min ; The second water 4 ℃, time 5min;

[0056] (3) Ozone water treatment: spread the cleaned high-temperature mushrooms into a pile of 1-2 cm thick, atomize the ozone water with a concentration of 15 mg / L, and spray evenly on the high-temperature mushrooms. The amount of ozone water used is 0.2% by weight;

[0057] (4) Ultrasonic digestion: frequency 35kHz, power 60w / cm 2 Ultrasonic digestio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com