Method for measuring concentration of total hardness Na2EDTA standard solution

A standard solution and total hardness technology, applied in the field of chemistry, can solve the problems of accuracy defects, deviation of measurement results, and high results, and achieve the effect of fast response time, fast test speed, and time-consuming solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1 (adopt method of the present invention to measure total hardness Na 2 EDTA standard solution concentration)

[0057] (1) Preparation of total hardness standard solution

[0058] Weigh 3.7269g EDTA disodium salt (Na 2 EDTA·2H 2 O=372.24), dissolved in 1L of water and shaken to obtain stable Na 2 EDTA standard solution.

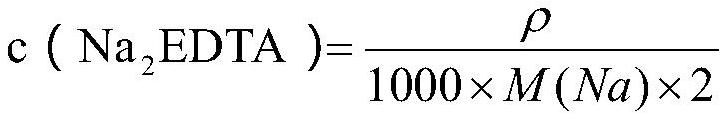

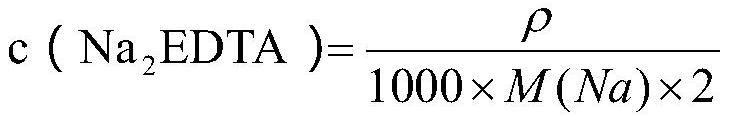

[0059] (2) The sample to be tested (Na 2 EDTA standard solution) determination

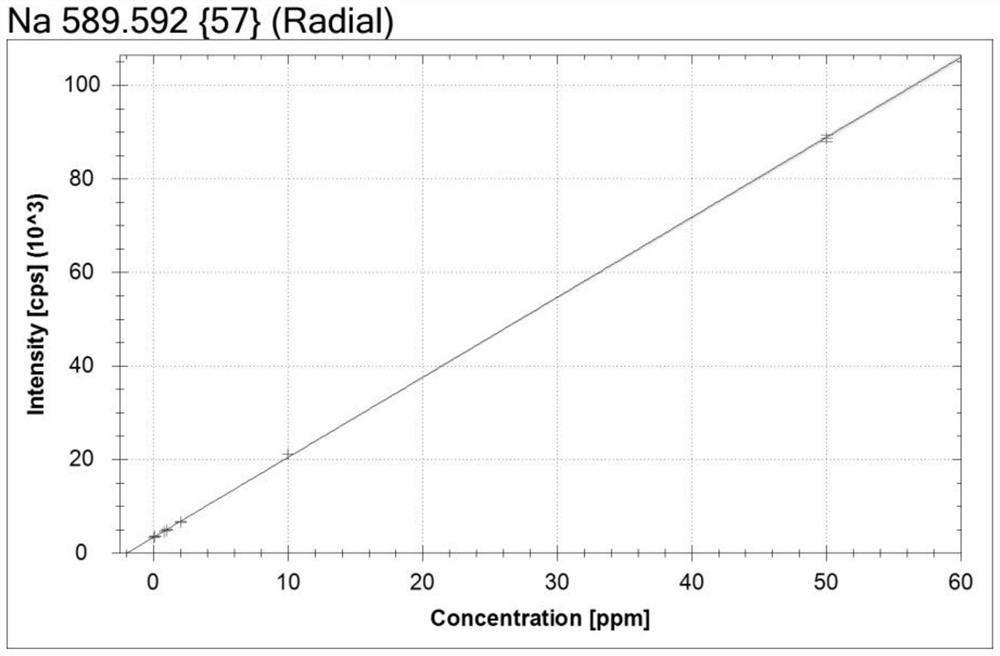

[0060] Take Na in step (1) 2 Add an appropriate amount of nitric acid to the EDTA standard solution sample and dilute it 20 times to measure the emission intensity of the sodium element in the sample (measure twice to get the average value); find the concentration of the target element sodium on the standard curve according to the emission intensity value.

[0061] (3) Blank test

[0062] Measure the blank sample according to the same conditions as the determination of the sample to be tested, and the blank sample is nitric acid with a concentration of 2...

Embodiment 2

[0066] Embodiment 2 (adopt method of the present invention to measure total hardness Na 2 EDTA standard solution concentration)

[0067] (1) Preparation of total hardness standard solution

[0068] Take by weighing 3.7207g EDTA disodium salt (Na 2 EDTA·2H 2 O=372.24), dissolved in 1L of water and shaken to obtain stable Na 2 EDTA standard solution.

[0069] (2) The sample to be tested (Na 2 EDTA standard solution) determination

[0070] Take Na in step (1) 2 Add an appropriate amount of nitric acid to the EDTA standard solution sample and dilute it 20 times to measure the emission intensity of the sodium element in the sample, and take the average value after two measurements; find the concentration of the target element sodium on the standard curve according to the emission intensity value.

[0071] (3) Blank test

[0072] Measure the blank sample according to the same conditions as the determination of the sample to be tested, and the blank sample is nitric acid with...

Embodiment 3

[0076] Embodiment 3 (adopt GB / T5750.4-2006 to calibrate Na with zinc standard solution 2 EDTA)

[0077] (1) Prepare zinc standard solution

[0078] Calibrate Na with zinc standard solution according to GB / T5750.4-2006 2 EDTA, process 7.1.3.5.1 Zinc standard solution: Weigh 0.6588g of pure zinc particles, dissolve in hydrochloric acid solution (1+1), place on a water bath and warm until completely dissolved, transfer to a volumetric flask, and dilute to 1000mL , and calculate the concentration of zinc standard solution according to formula (3) to be 0.01007mol / L.

[0079]

[0080] c(Zn) represents the concentration of zinc standard solution in moles per liter (mol / L); M represents the mass of zinc in grams (g); 65.39 represents the mass of 1 mol of zinc in grams (g).

[0081] (2)Na 2 Preparation of EDTA standard solution

[0082] Get the Na prepared in Example 1 2 Two parts of EDTA standard solution

[0083] (3) Confirm Na according to the concentration of zinc standa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com