Fluidized bed gas distributor, fluidized bed reactor and gasification method

A technology of gas distributor and gas distribution plate, which is applied in the field of coal gasification, can solve the problems of large dead zone area, uneven contact, local high temperature, etc., and achieve the effects of uniform heat distribution, improved uniformity, and enhanced fluidization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

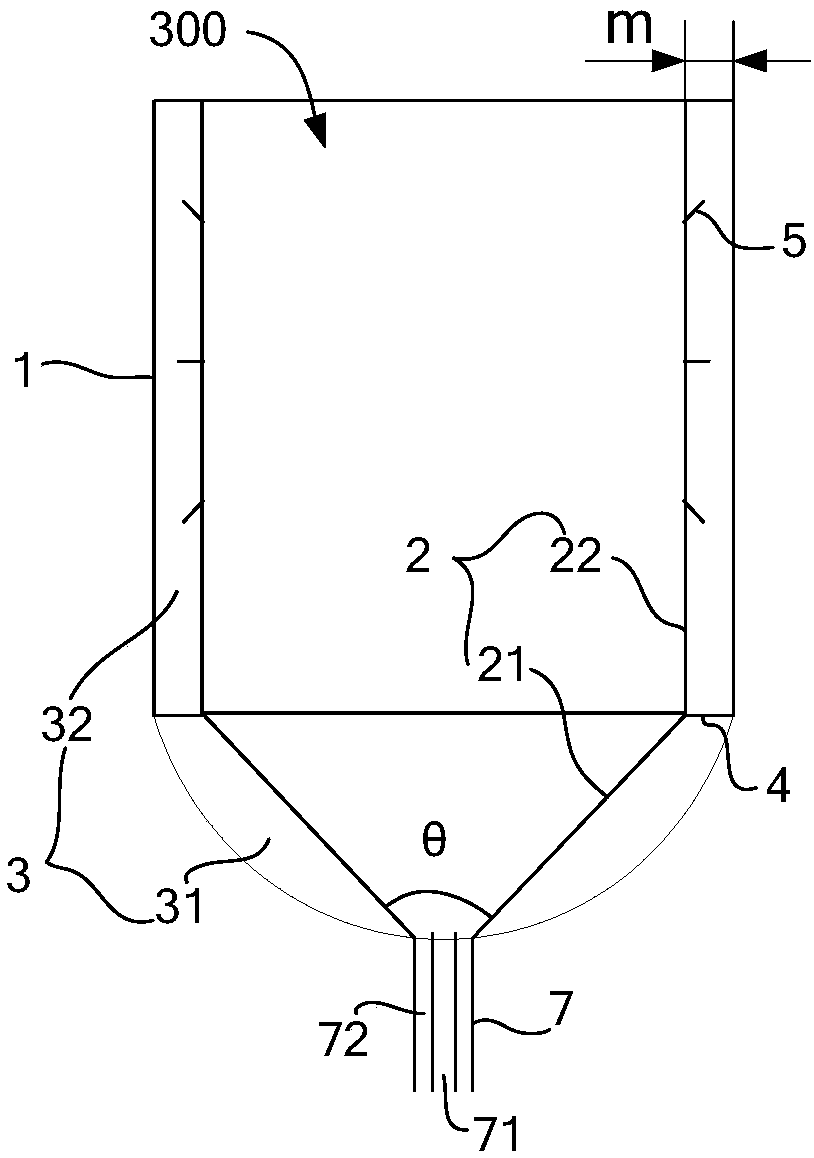

[0026] Such as image 3 As shown, the embodiment of the present invention provides a gas distributor for a fluidized bed, which includes a cylindrical first shell 1 with an open upper end and a sealed lower end. The first shell 1 is provided with a gas distribution plate 2 for gas distribution. A gas chamber 3 is formed between the plate 2 and the first housing 1. The gas chamber 3 includes a first gas chamber 31 and a second gas chamber 32 isolated from each other. The gas distribution plate 2 includes a first gas distribution plate 21 and a second gas distribution plate 21. Distribution plate 22, the second gas distribution plate 22 is located above the first gas distribution plate 21, the second gas distribution plate 22 is cylindrical and vertically arranged, the first gas distribution plate 21 is connected to the lower end of the second gas distribution plate 22 , the first gas distribution plate 21 corresponds to the first gas chamber 31 , and the second gas distribution...

Embodiment 2

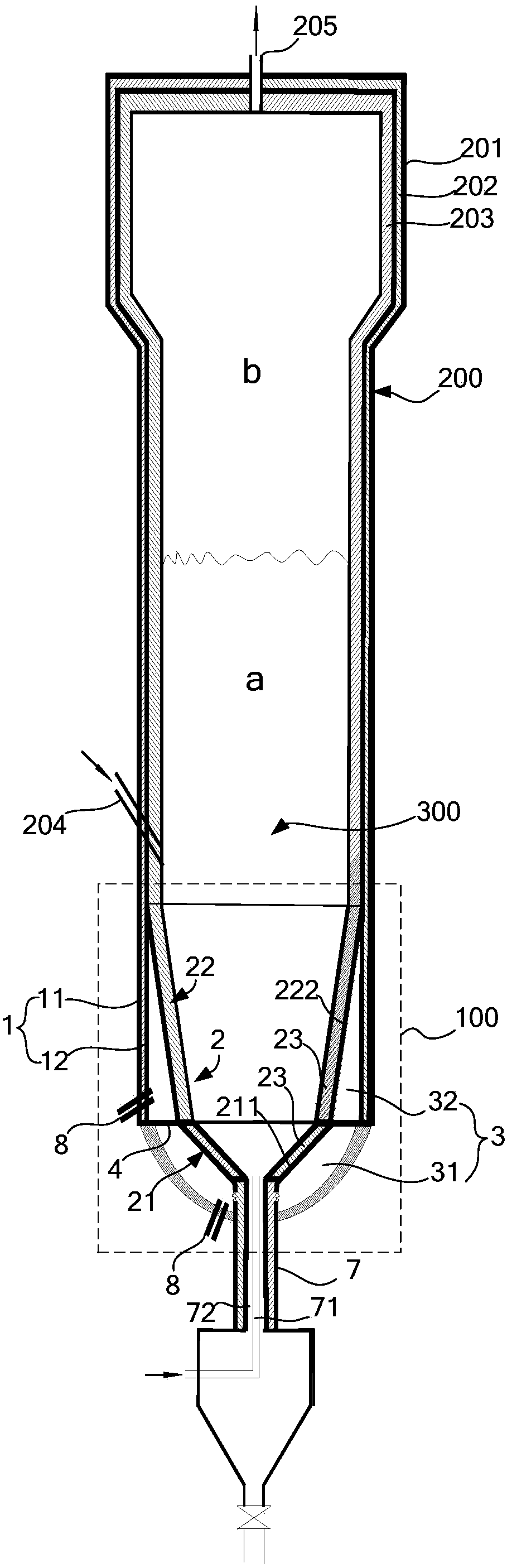

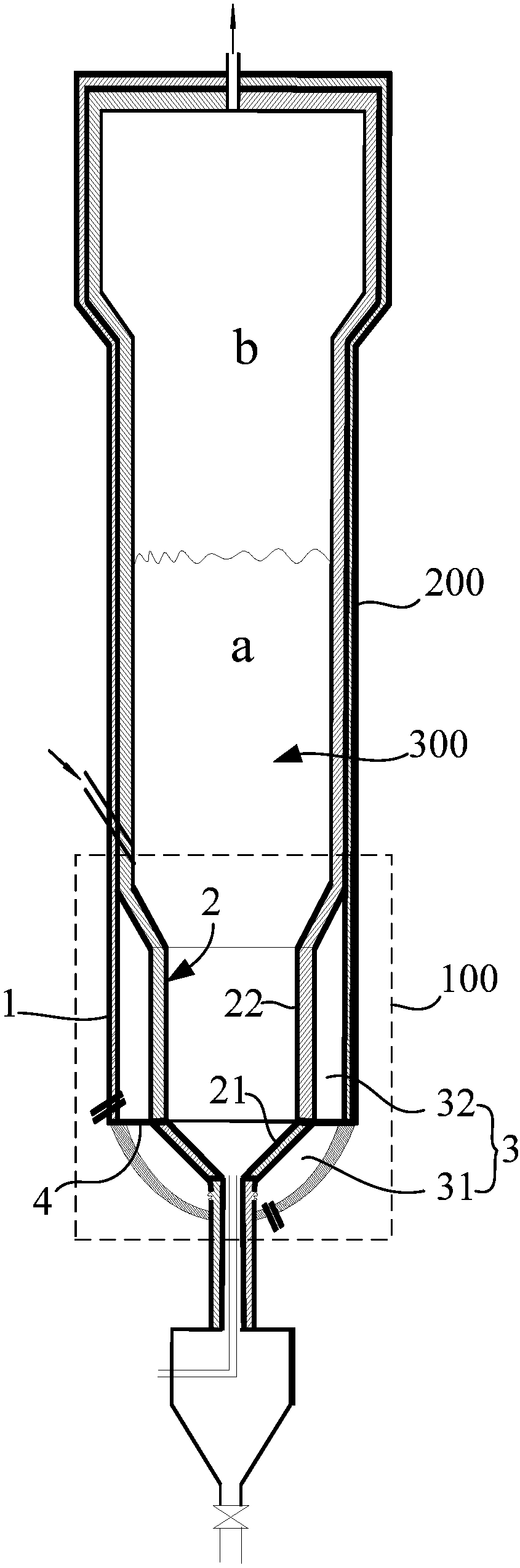

[0059] Such as figure 1 As shown, the embodiment of the present invention provides a fluidized bed reactor, including a cylindrical second shell 200 with a sealed upper end and an open lower end and the fluidized bed gas distributor 100 described in Embodiment 1. The lower end of the second housing 200 is sealingly connected with the upper end of the first housing 1 of the fluidized bed gas distributor 100, so that a reaction chamber is formed between the second housing 200 and the gas distribution plate 2 of the fluidized bed gas distributor 100 Room 300.

[0060] Wherein, the first shell 1 and the second shell 200 can be integrally formed (for example figure 1 shown), the lower end of the second housing 200 and the upper end of the first housing 1 may also be sealed and connected through a connection structure, which is not specifically limited here.

[0061] Since the fluidized bed gas distributor 100 included in the fluidized bed reactor provided by the embodiment of the...

Embodiment 3

[0066] Such as Figure 7 As shown, the embodiment of the present invention provides a gasification method of a fluidized bed reactor as described in Example 2, comprising the following steps:

[0067] S1. Send carbonaceous material (such as coal) with a certain amount of catalyst loading into the reaction chamber 300, and at the same time send the gasification agent into the first gas chamber 31 and the second gas chamber 32 respectively, and send it into The gasification agent in the first gas chamber 31 enters the reaction chamber 300 through the first gas distribution plate 21, and the gasification agent sent into the second gas chamber 32 enters the reaction chamber through the second gas distribution plate 22 chamber 300, so that the carbonaceous material and the gasifying agent undergo a gasification reaction;

[0068] Among them, such as figure 1 As shown, the carbonaceous material can be fed into the reaction chamber 300 through the feed port 204 provided on the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com