Multi-functional multi-level translational swing electrode slurry electrolyzer

An electrolytic cell and multi-level technology, applied in the direction of electrolytic components, electrolytic processes, cells, etc., can solve the problems of occupying the installation position of the agitator and poor stirring effect, and achieve the effects of small environmental pollution, elimination of tailings, and reduction of hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

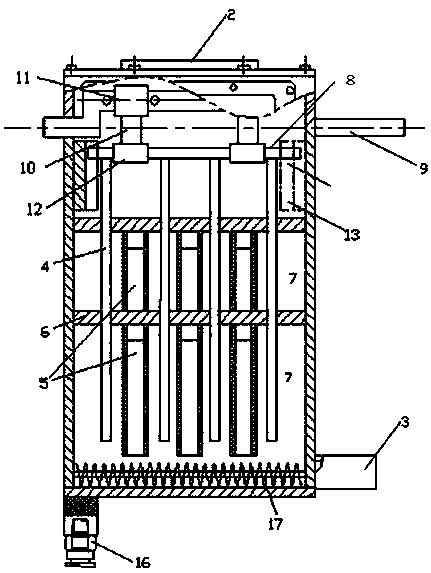

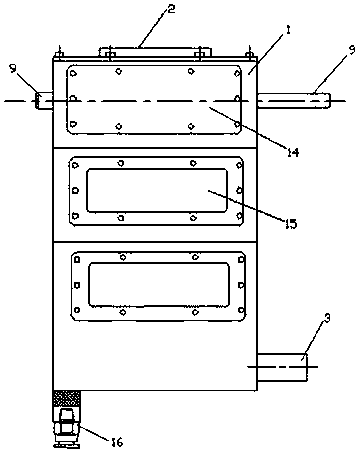

[0023] Such as Figure 1-Figure 2 As shown, the multi-functional multi-level translational swing electrode slurry electrolyzer of the present invention includes an electrolytic cell body 1, which includes an upper feeding slurry port 2 and a discharge screw 17 at the bottom, and the discharge screw is facing the electrolytic cell There is a slag outlet 3 on one side of the bottom of the body, and a leaching liquid outlet 16 is set under the other side, and an anode 4 and a cathode 5 are set in the electrolytic cell body, which also includes:

[0024] Separator 6, at least one layer of separator is provided in the electrolytic cell body, and the electrolytic cell is divided into at least two electrolytic chambers 7; the cathode is fixed on each layer of separator and the bottom of the electrolytic cell, and the outer surface is wrapped with a diaphragm;

[0025] Beam 8, which is arranged above the body of the electrolytic cell, and the anode passes through each layer of partiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com