Diesel engine nozzle blockage simulation testing method and device

A diesel engine and simulation test technology, which is applied in the direction of engine testing, internal combustion engine testing, machine/structural component testing, etc., can solve the problems that diesel cannot be used, and achieve the effect of shortening test time and high test repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

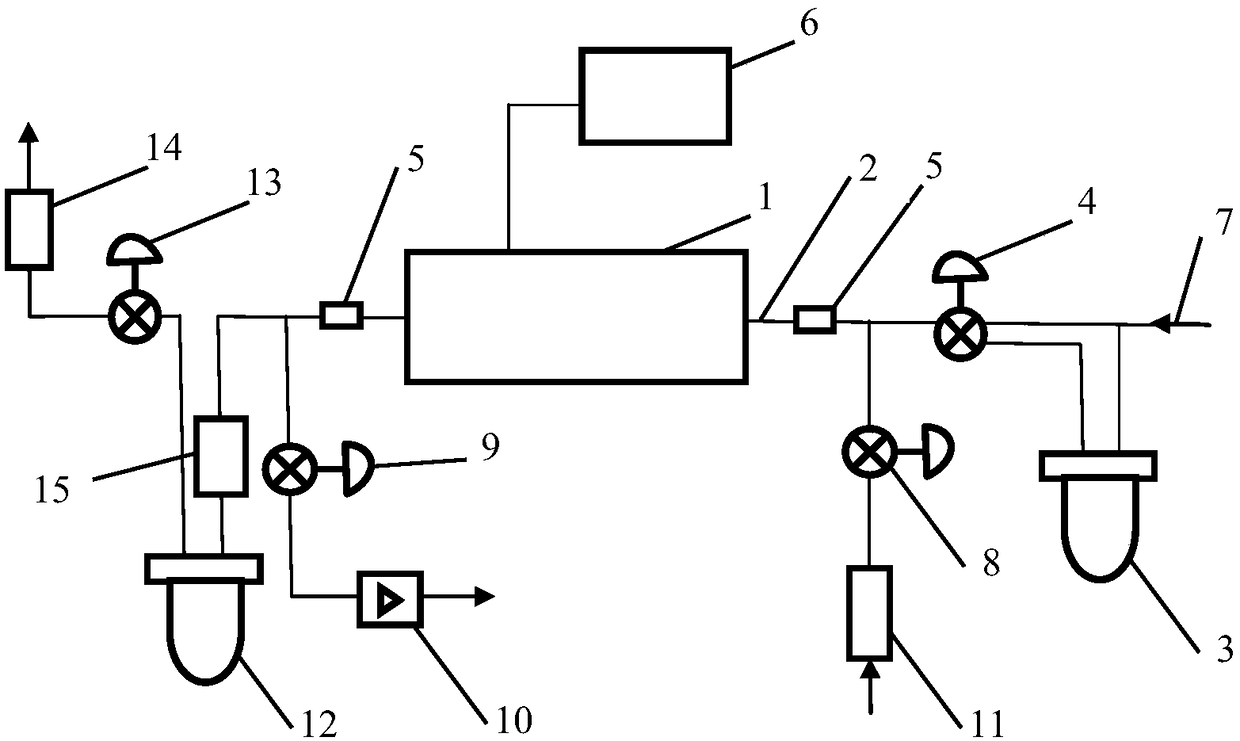

[0035] The diesel engine nozzle clogging simulation test method and equipment of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] Such as figure 1 As shown, in the embodiment of the diesel engine nozzle clogging simulation test equipment provided by the present invention, the metal capillary 2 passes through the metal bath 1, and the two ends of the metal capillary 2 are respectively the inlet and the outlet of the metal capillary 2, and the inlet and the outlet are all controlled by The quick twist joint 5 is connected and sealed, and the temperature of the metal bath 1 is controlled by the control device 6 .

[0037] In this embodiment, the metal capillary 2 has a total length of 200 mm, and the first 2 / 3 section is an inner hole with a diameter of about 1 mm, and the rear 1 / 3 section has an aperture that is reduced by half to form a narrow mouth. The pore size is small, and there is a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com