Metal tension and torsion combine deformation mechanics and sound emission characteristic testing and analyzing method

An analysis method and feature testing technology, which can be used to test the strength of materials by applying stable torsion, test the strength of materials by applying stable tension/compression, and analyze materials. It can solve the problems of different stress and failure surface positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

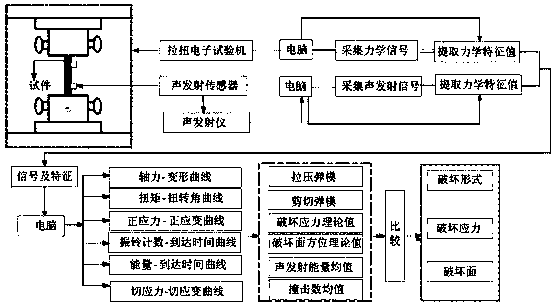

[0101] A method for testing and analyzing metal tension-torsion combined deformation mechanics and acoustic emission characteristics in this embodiment, the specific steps are as follows:

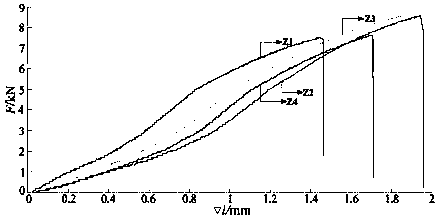

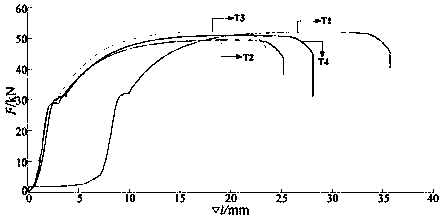

[0102] Select the tensile and torsion test pieces of cast iron, carbon steel, and aluminum alloy, and carry out the tensile-torsional acoustic emission test according to the test plan in Table 1. Each metal material is subjected to 4 different tensile and torsion loading rate tests, and a total of 12 Tensile torsion loading test. The cast iron test pieces are numbered Z1-Z4, the carbon steel test pieces are numbered T1-T4, and the aluminum alloy test pieces are numbered L1-L4.

[0103] The specific loading rate and loading path scheme are shown in Table 1 and Table 2, respectively.

[0104] Table 1 Loading rate schemes for tensile torsion of cast iron, carbon steel and aluminum alloy

[0105]

[0106]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com