Drop hammer type pressure generator pneumatic control system

A pneumatic control system and control system technology, applied in the mechanical field, can solve the problems of secondary impact, low positioning accuracy of falling hammer, inconvenient laboratory layout and operation, etc., and achieve reliable working results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

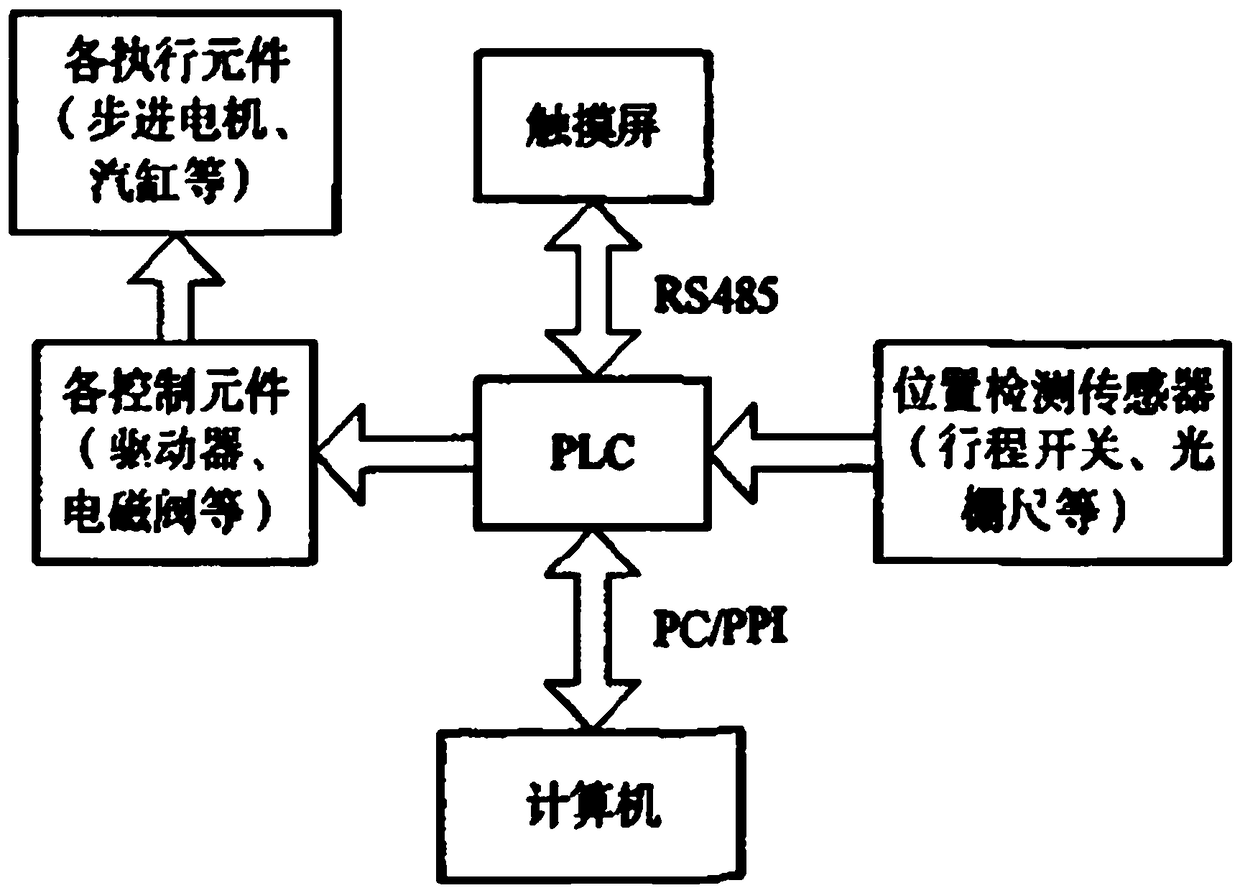

[0016] Such as figure 1 , first of all, the system needs to have actuators and control elements that can lift the weight, position at any height and hold the hammer twice; secondly, in order to realize automatic operation, it needs a controller and position detection sensor; finally, in order to improve the man-machine interface, A touch screen and an upper computer are required to communicate with the controller.

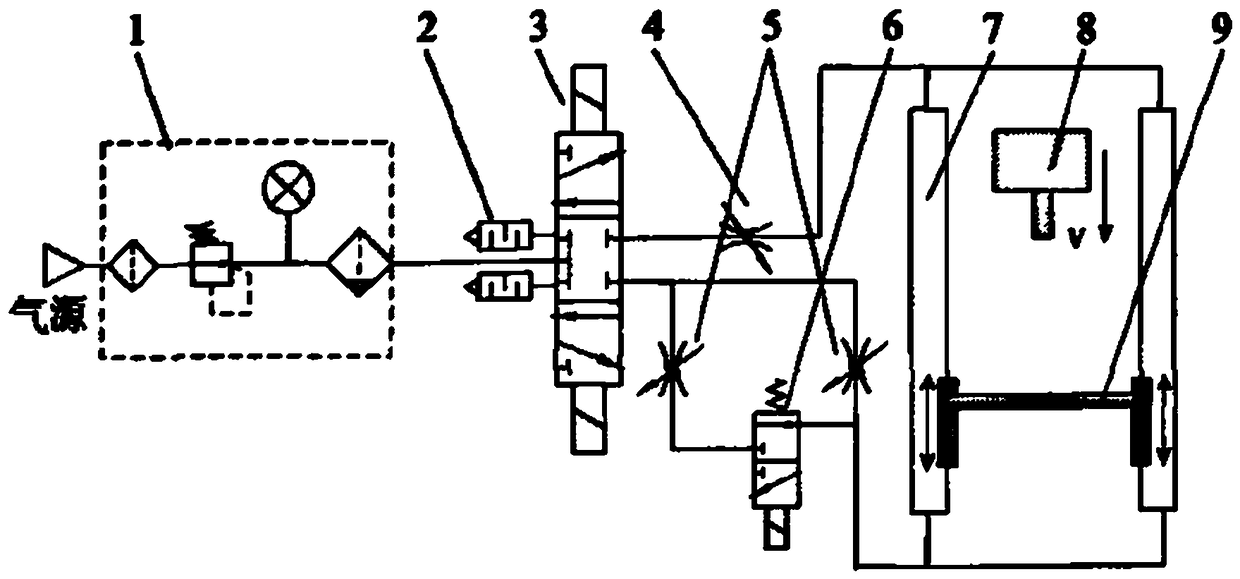

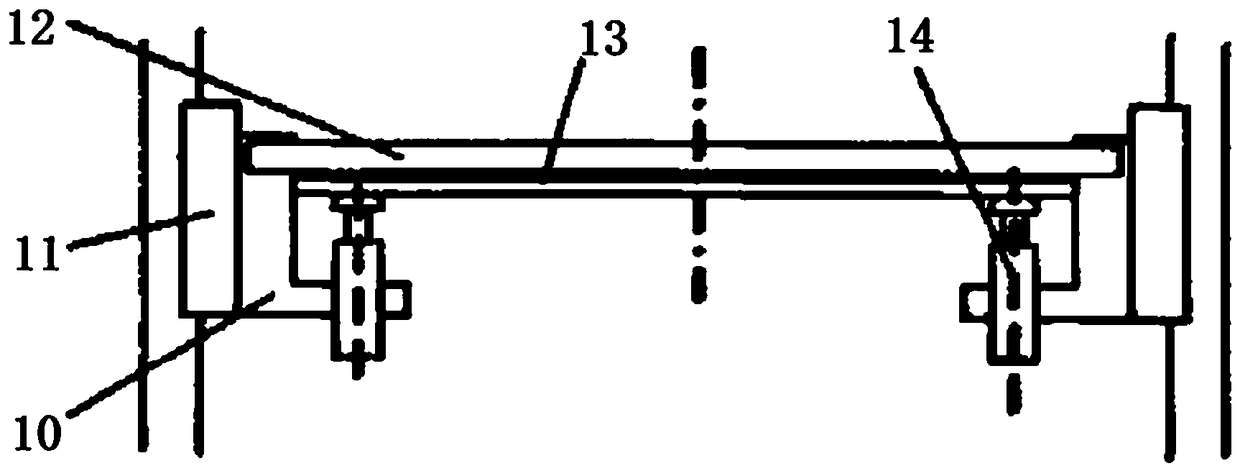

[0017] As the core of the control system, PLC directly completes the coordinated control and motion position detection of each component of the device. It is equipped with a touch screen as an on-site debugging device, and can also remotely control and monitor the operating status of the system through a computer. The stepper motor drives the precision ball screw to perform arbitrary height positioning, combined with the grating scale for closed-loop contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com