Transverse p-n-n microcavity-structured Ge light-emitting device and preparation method thereof

A p-n-n, light-emitting device technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of high technical level requirements, poor thermal stability, increase of non-radiative recombination centers, etc., to achieve simple process preparation, superior luminous performance, enhanced The effect of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

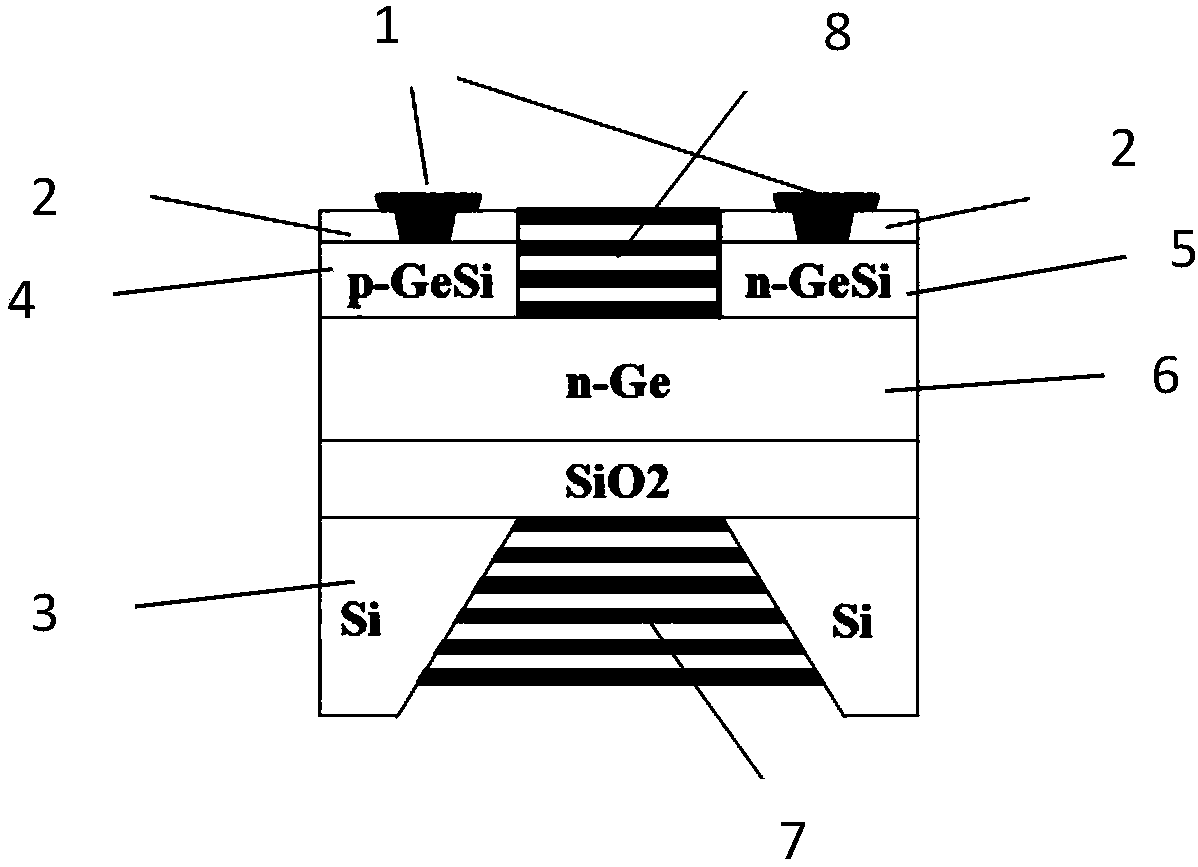

[0027] The purpose of the present invention is to carry out lateral heterostructure design on Ge light-emitting devices, supplemented by microcavity structure design, and realize p-GeSi / n-Ge / n by means of distributed Bragg reflector (DBR) structures at the top and bottom of the active layer -GeSi lateral structure high-efficiency light-emitting device, providing a method for preparing a lateral p-n-n microcavity structure Ge light-emitting device with simple process, compatible with mature silicon CMOS process and superior performance.

[0028] Such as figure 1 As shown, a Ge light-emitting device with a lateral p-n-n microcavity structure includes an active layer n-Ge layer 6, and the lower surface of the n-Ge layer 6 is Si / SiO 2 Structure 3, n-Ge layer 6 with Si / SiO 2 Structure 3 constitutes a highly dope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com