Environment-friendly elver puffed floating granular compound feed and preparation method of same

A compound feed and environment-friendly technology, which is applied in the field of environment-friendly juvenile puffed floating granule compound feed and its preparation field, can solve problems such as restricting the development of eel puffed and floating granule technology, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

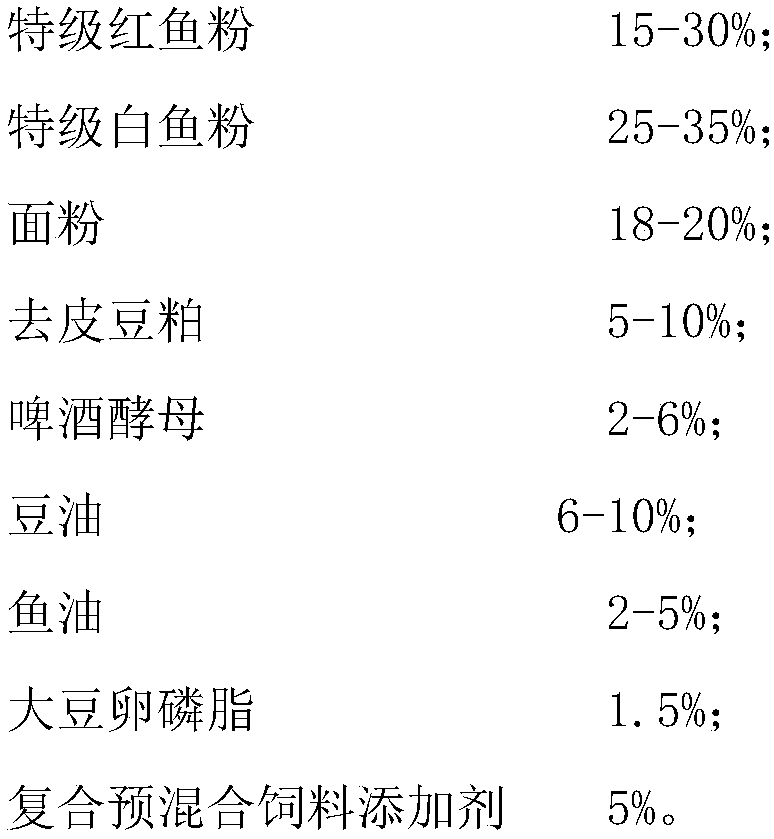

[0061] Example 1: Preparation of environmentally-friendly elver extruded floating pellet compound feed

[0062] Raw materials: see Table 1.

[0063] Preparation method: weigh the special grade red fish meal, special grade white fish meal, flour, peeled soybean meal, brewer's yeast, soybean oil, fish oil, soybean lecithin and compound premix feed additives;

[0064] Crushing: crushing the dehulled soybean meal in the raw material;

[0065] In addition to impurities;

[0066] The first batching and mixing: mix the special red fish meal, special white fish meal, flour, crushed dehulled soybean meal, brewer's yeast and compound premix feed additives in the mixer to make the mixing uniformity CV value less than 7%;

[0067] Ultrafine pulverization of mixed raw materials: After the above-mentioned obtained is pulverized by an ultrafine pulverizer, 98% of the materials are passed through a 100 mesh screen;

[0068] The second mixing of raw materials: spray soy lecithin and half of the weight of ...

Embodiment 2

[0083] Example 2: Preparation of environment-friendly elver extruded and floating pellet compound feed

[0084] Raw materials: see Table 1.

[0085] Preparation method: it can be prepared according to the processing technology of extruded floating granular compound feed and the vacuum spraying technique after extruded granulation.

Embodiment 3

[0086] Example 3: Preparation of environmentally-friendly elver extruded floating pellet compound feed

[0087] Raw materials: see Table 1.

[0088] Preparation method: it can be prepared according to the processing technology of extruded floating granular compound feed and the vacuum spraying technique after extruded granulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com