Skin-core aromatized filter rod and preparation method thereof

A technology of skin-core type and fragrance filter rods, which is applied in the direction of e-liquid filter elements, applications, tobacco, etc., can solve the problems of volatilization and affecting the effect of fragrance retention, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

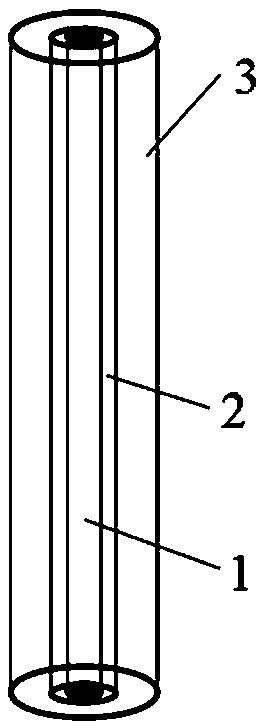

[0021] First, soak the cotton thread in menthol and mix the mixture of polycaprolactone and polyethylene glycol at a ratio of 5:1. The molecular weight of polycaprolactone is 20,000, and the molecular weight of polyethylene glycol is 800. After the above-mentioned polymer is heated to 60°C, a polymer solution is formed; the above-mentioned incense string core layer containing menthol is immersed in the liquid polymer, so that the surface of the incense string core layer is completely covered with a layer of polymer solution, and after cooling A sheath-core type scented thread core can be obtained. The sheath-core fragrance thread core and the cellulose diacetate tow are formed on the filter rod forming machine at the same time, and the tow and the sheath-core linear fragrance slow-release material (that is, the fragrance thread core) are bonded together by a plasticizer. Together, a sheath-core type fragranced filter rod is formed, the plasticizer addition ratio is 6% of the f...

Embodiment 2

[0025] Firstly, soak the incense thread in the dried tangerine peel extract and mix the mixture of polycaprolactone and polyethylene glycol at a ratio of 2:3. The molecular weight of polycaprolactone is 30,000, and the molecular weight of polyethylene glycol is 1,000. After the above-mentioned polymer is heated to 55°C, a polymer solution is formed; the above-mentioned incense string core layer containing orange peel extract is immersed in the liquid polymer, so that the surface of the incense string core layer is completely covered with a layer of polymer solution, and cooled Finally, the sheath-core type scented thread core can be obtained. The sheath-core fragrance thread core and the polylactic acid tow are formed on the filter rod forming machine at the same time, and the tow and the sheath-core linear fragrance slow-release material (that is, the fragrance thread core) are bonded together by a plasticizer. A sheath-core type fragranced filter rod is formed, the plasticiz...

Embodiment 3

[0027] First, soak the incense thread in the moss extract, mix the mixture of polycaprolactone and polyethylene glycol at a ratio of 3:2, the molecular weight of polycaprolactone is 40000, and the molecular weight of polyethylene glycol is 1500 . After the above-mentioned polymer is heated to 63°C, a polymer solution is formed; the above-mentioned incense string core layer containing tree moss extract is immersed in the liquid polymer, so that the surface of the incense string core layer is completely covered with a layer of polymer solution, After cooling, a sheath-core scented thread core can be obtained. The sheath-core fragrance thread core and the diacetate cellulose tow are formed on the filter rod forming machine at the same time, and the tow and the sheath-core linear fragrance slow-release material (that is, the fragrance thread core) are bonded together by a plasticizer , forming a sheath-core type fragranced filter rod, the plasticizer addition ratio is 8% of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com