A dust machine that is easy to clean and polish ceramics

A ceramic and dust technology, applied in the field of ceramic processing equipment, can solve the problems of single function, lung damage, simple structure of dust processor, etc., to achieve the effect of convenient use, prevention of escape everywhere, and improvement of universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

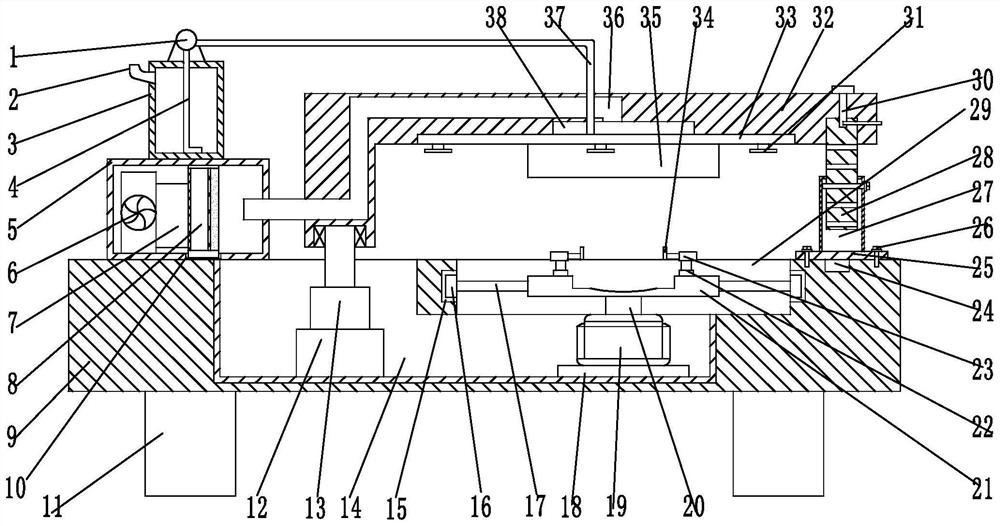

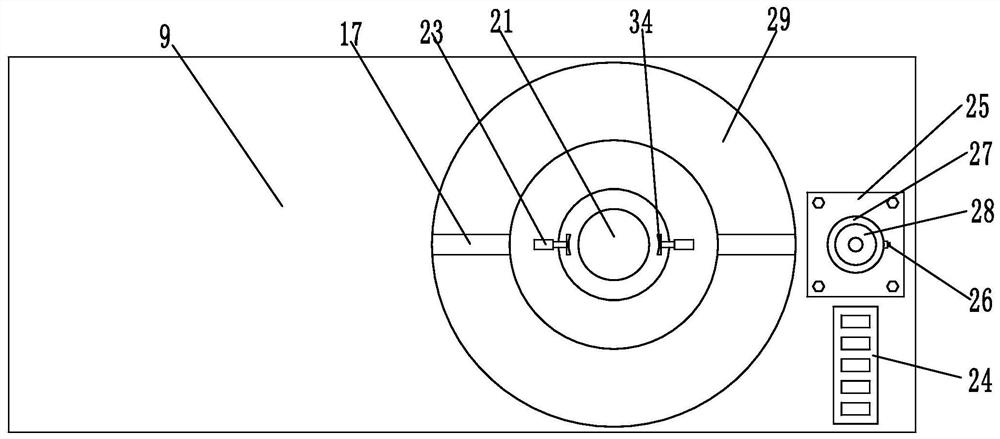

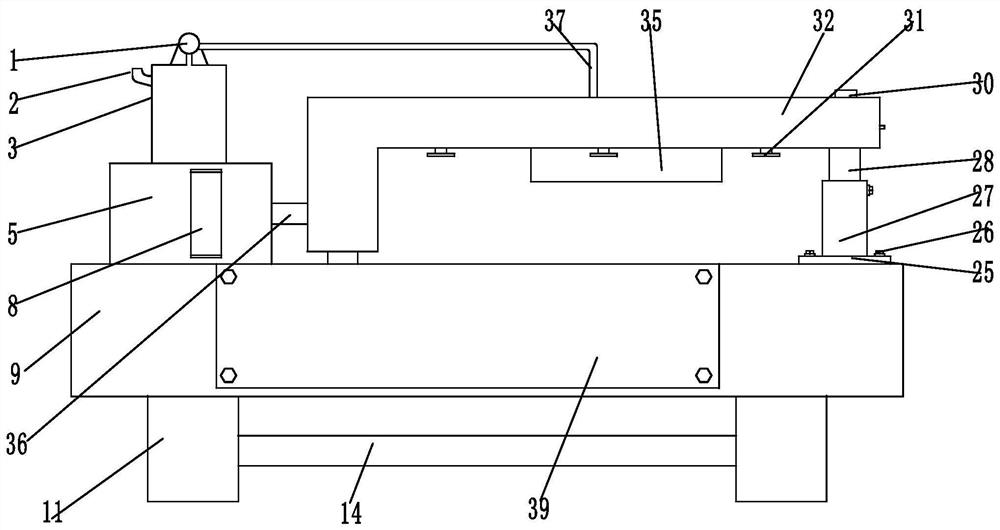

[0022] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

[0023] see Figure 1-5, a dust machine that is convenient for cleaning ceramics and grinding; it includes an operating table 9, a drive bin 14 and a control device 24; the left side of the upper surface of the operating table 9 is provided with a dust collection box 5; On the upper surface of the operating table 9, an exhaust fan 6 is installed inside; the exhaust fan 6 is installed inside the dust collection box 5, and it is electrically connected with the control device 24 through a wire; the control device 24 is embedded in the operating table 9 On the right side of the upper surface, and a control button is installed on it, so as to control the whole device; the opening of the exhaust fan 6 is connected with a connecting pipe 7; one end of the connecting pipe 7 is connected to the opening of the exhaust fan 6, and the other end is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com