Preparation method of low-cost sulfur palladium alloy resisting composite film

The technology of a palladium alloy membrane and a composite membrane is applied in the field of preparation of a sulfur-resistant palladium alloy composite membrane, which can solve the problems of pinhole defects, poisoning of the Pd composite membrane, decreased hydrogen permeation selectivity, etc., and achieves enhanced stability, low cost, The effect of high hydrogen permeability and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

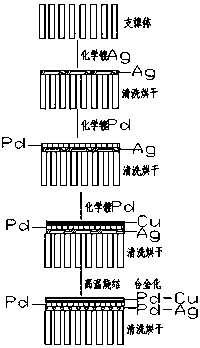

[0015] Such as figure 1 As shown, the present invention is a preparation method of a low-cost anti-sulfur-palladium alloy composite membrane. The low-cost anti-sulfur-palladium alloy composite membrane includes a palladium alloy membrane or a palladium double-alloy composite membrane on the surface of a porous support. The palladium composite membrane on the surface of the porous support adopts one-time alloying to prepare the Pd-Ag / Pd / Pd-Cu double alloy composite membrane, and the steps of the preparation method are:

[0016] (1) First, clean the surface of the support body. After activation and sensitization, put it into the silver plating solution at 323K~353K for electroless Ag plating. The thickness of the Ag film is 1~2μm. Wash thoroughly in deionized water and dry;

[0017] (2) When performing electroless Pd plating, put the support body coated with Ag film into the palladium plating solution and continue electroless Pd plating on the prepared Ag film. The thickness of...

Embodiment 1

[0029] (1) First, clean the surface of the Ti support body, and after activation and sensitization, put it into the gold plating solution at 333K for 30 minutes of electroless Ag plating. The composition of the silver plating solution is: AgNO 3 (2g / L), Na 2 .EDTA (30g / L), NH 4 OH (25%, 300ml / L), N 2 h 2 (0.1mol / L). The thickness of the plated Ag film is 1 μm, and the support body after chemical deposition is thoroughly cleaned in 373K deionized water, and dried at 323K;

[0030](2) When performing electroless Pd plating, put the support body coated with Au film into the palladium plating solution and continue electroless Pd plating on the prepared Ag film for 5h. The composition of the palladium plating solution is: SnCl 2 (1g / L), PdC 2 l (1g / L), HCl (36%), EDTA.2Na (30g / L), N 2 h 2 (0.1mol / L), NH 4 OH (25%); the thickness of the plated Pd film is 2 μm, and the support body after the chemical plating of Pd is cleaned and dried in the same way as that of the chemical p...

Embodiment 3

[0039] (1) First clean the surface of the Ti support body, after activation and sensitization, put it into the silver plating solution at 333K for electroless Ag plating for 40min, the composition of the silver plating solution is: AgNO 3 (4g / L), Na 2 .EDTA (40g / L), NH 4 OH (25%, 400ml / L), N 2 h 2 (0.4mol / L). The thickness of the plated Ag film is 1.4 μm, and the support body after chemical deposition is thoroughly cleaned in 373K deionized water, and dried at 373K;

[0040] (2) When performing electroless Pd plating, put the support body coated with Ag film into the palladium plating solution and continue electroless Pd plating on the prepared Ag film for 7h. The composition of the palladium plating solution is: SnCl 2 (3g / L), PdC 2 l (3g / L), HCl (38%), EDTA.2Na (50g / L), N 2 h 2 (0.4mol / L), NH 4 OH (28%,); the thickness of the plated Pd film is 3.0 μm, and the support body after the electroless plating of Pd is cleaned and dried by the same method as that of the elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com