Centrifugal machine for bolt galvanizing line

A centrifuge and production line technology, applied in the field of centrifuges, can solve the problems affecting the galvanized quality of hot-dip galvanized bolts, uneven distribution of centrifuge containers, unstable operation of centrifuges, etc. The effect of stable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

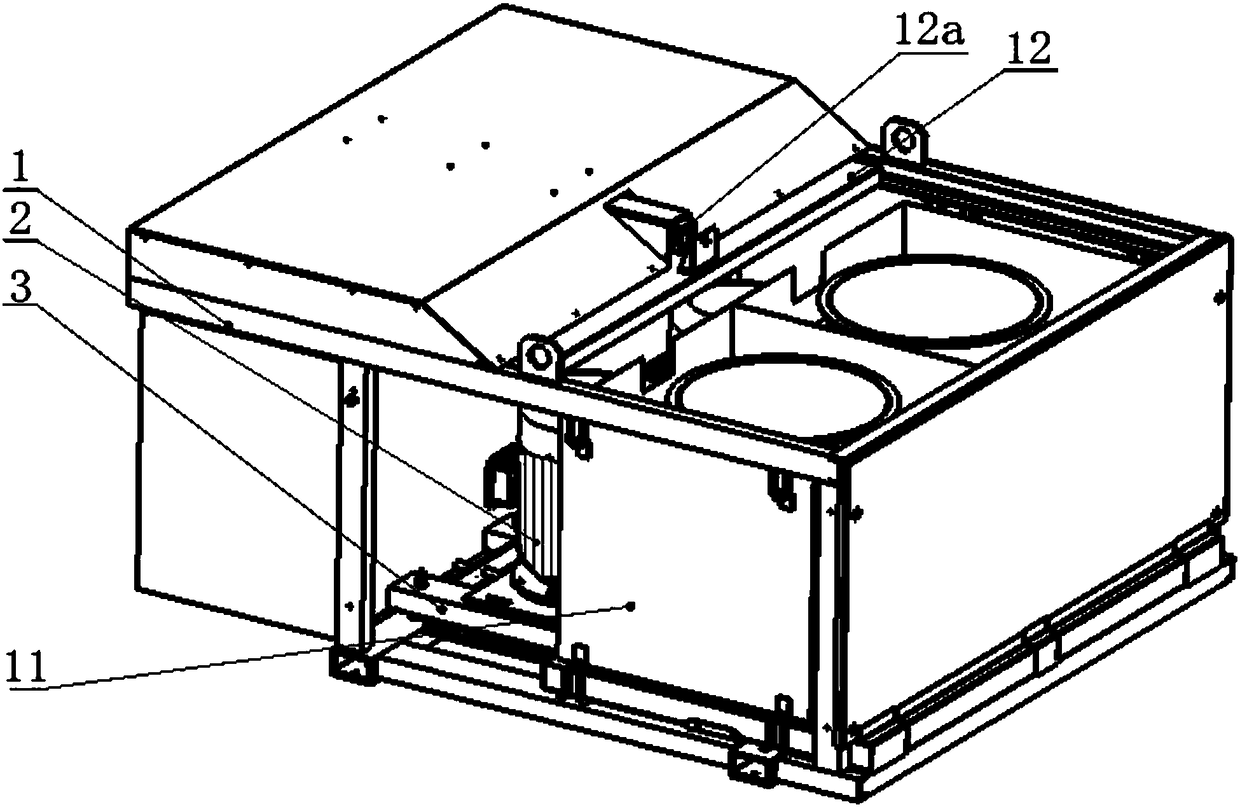

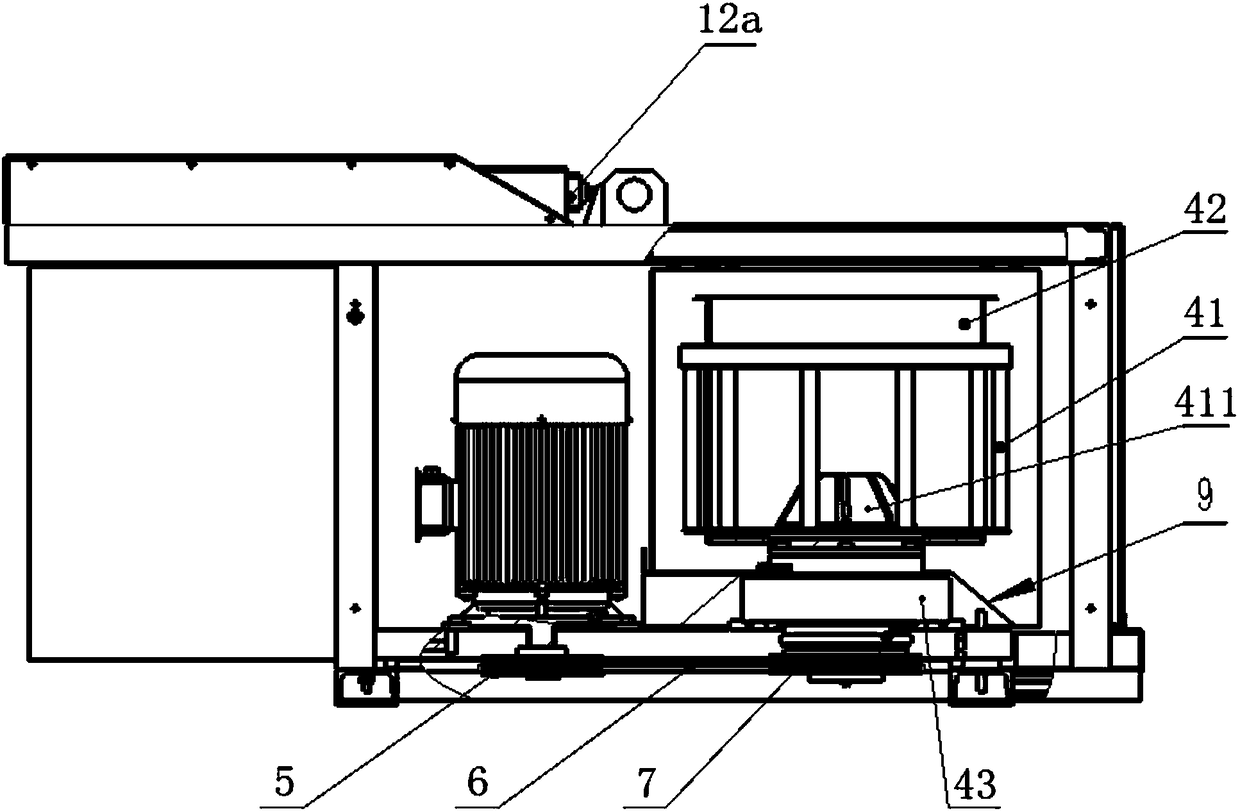

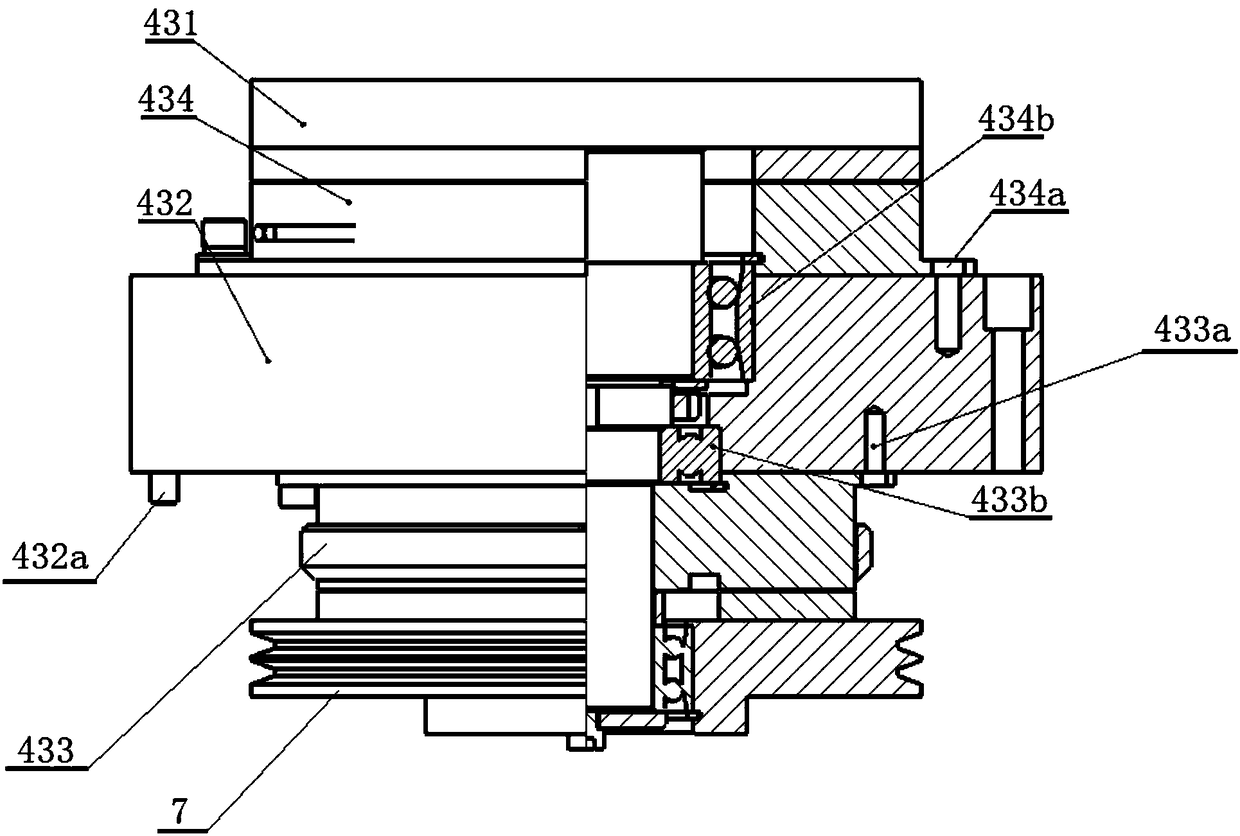

[0020] As shown in the figure, a centrifuge for a bolt galvanizing production line includes a centrifuge frame 1, a driving motor 2 and a centrifugal assembly are arranged side by side in the centrifuge frame 1, and the driving motor 2 is vertically fixed on the centrifuge On the mounting frame 3 in the machine frame 1, and the output shaft of the drive motor 2 protrudes vertically downwards, the centrifugal assembly includes a centrifugal cylinder 41, a bolt bucket 42 is arranged in the centrifugal cylinder 41, and the bottom of the centrifugal cylinder 41 It is coaxially provided with a drive shaft part 43; the output shaft of the drive motor 2 is fixedly equipped with a small motor pulley 5, and the small motor pulley 5 is connected with the large pulley 7 installed on the drive shaft part 43 by a belt 6, The center of the upper surface of the bottom of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com