Air cushion type surface pressure film coating process and device

A coating process and surface pressure technology, which is applied to the device and coating of the surface coating liquid, can solve the phenomenon that there is no color coating film coating, the edge of the coating is wrinkled, folded, and micro-concave-convex And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

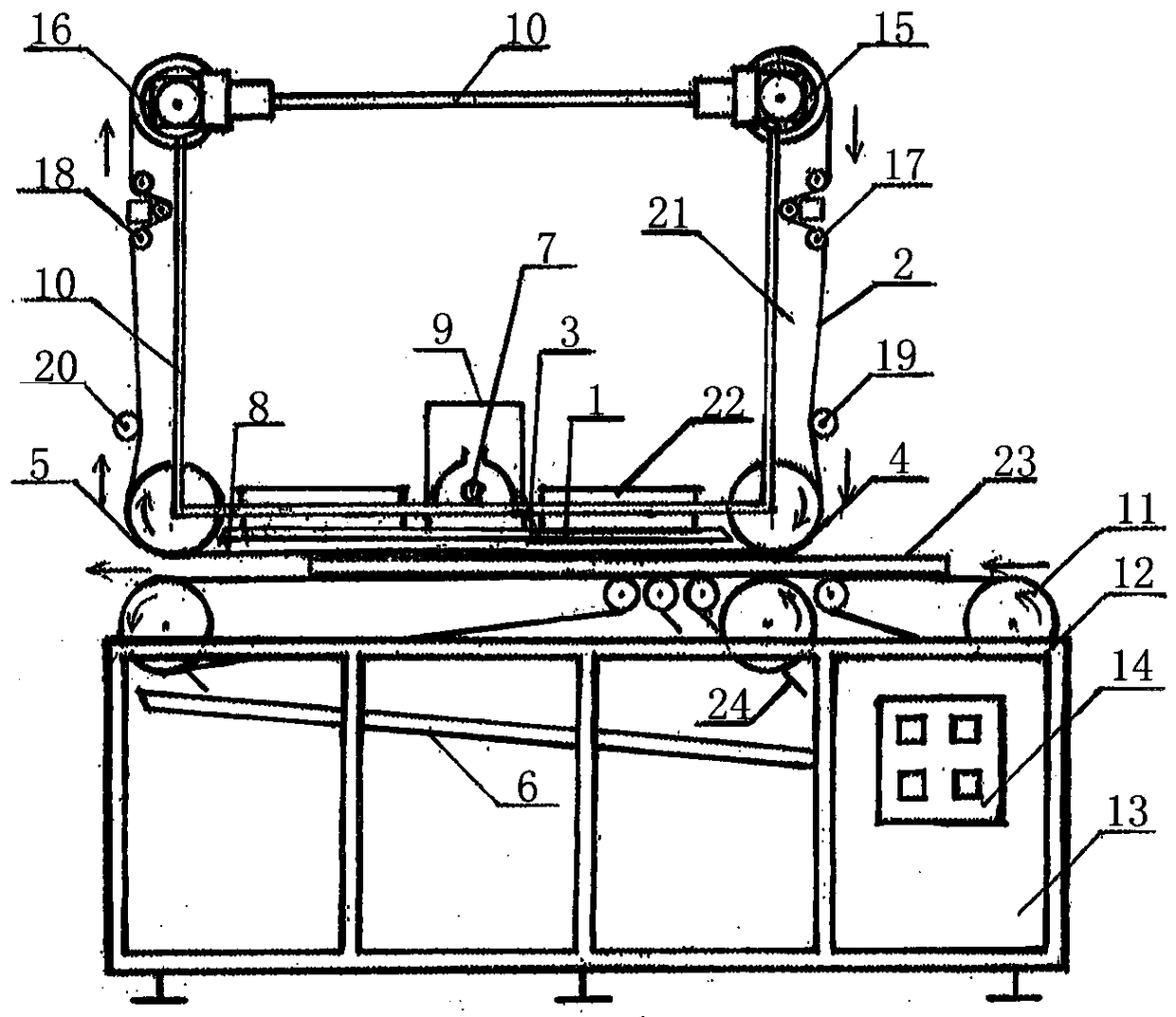

[0071] Embodiment one of the present invention: with reference to accompanying drawing

[0072] figure 1 Embodiment 1 is the combination of the film surrounding frame and the coating object carrying device of the air pressure cushion type surface pressure film coating device including an air pressure equalization plate to form a complete structure of the air pressure cushion type surface pressure film coating device schematic diagram;

[0073] An air pressure cushion type surface pressure film coating device structure, comprising:

[0074] Frame 12, the film surrounding frame 21 of the air pressure cushion type surface pressure film coating device 1 including an air pressure equalization plate, the coating object carrying device 11, the speed regulating motor, the power distribution system 13, and the operation box 14;

[0075] An air pressure cushion type surface pressure film coating device consists of:

[0076] The film surrounding frame 21 of the air pressure cushion ty...

Embodiment 2

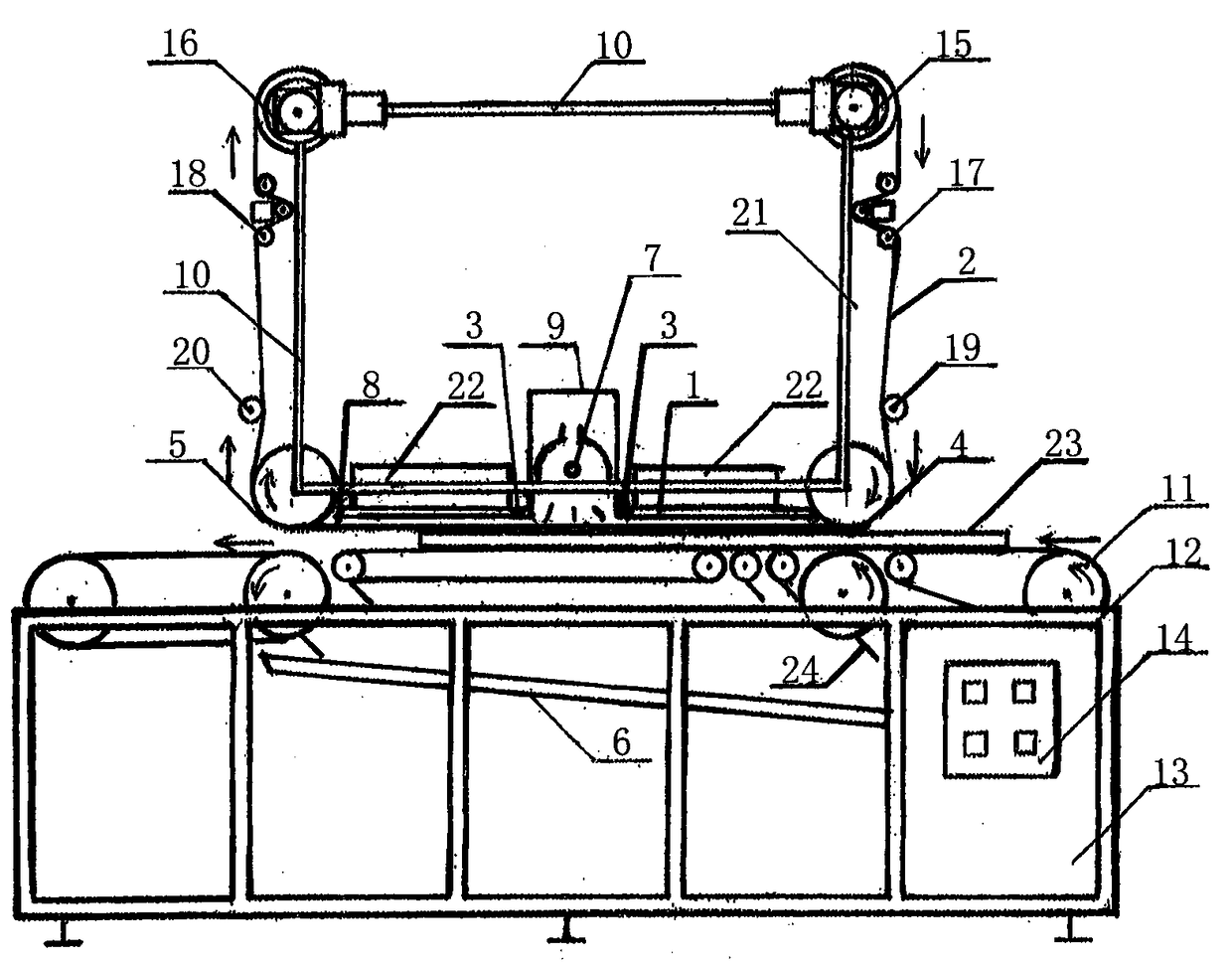

[0091] Embodiment two of the present invention: with reference to accompanying drawing

[0092] figure 2 Embodiment 2 is to combine the film surrounding frame and the coating object carrying device of the air pressure cushion type surface pressure film coating device including two air pressure equalization plates to form a complete air pressure cushion type surface pressure film coating device Schematic.

[0093] An air pressure cushion type surface pressure film coating device structure, comprising:

[0094] Frame 12, the film surrounding frame 21 of the air pressure cushion type surface pressure film coating device 1 including two air pressure equalization plates, the coating object carrying device 11, the speed regulating motor, the power distribution system 13, and the operation box 14;

[0095] The air pressure cushion type surface pressure film coating device with two air pressure equalization plates in the film surrounding frame of the air pressure cushion type surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com