A welding rework assessment method

A welding seam repair and repair technology, applied in welding equipment, metal processing equipment, material analysis using radiation, etc., can solve the problem that the method of dividing the heat-affected zone cannot be guaranteed to be effective, the hidden danger of product quality, and the inability to quickly and effectively divide the heat-affected zone. Areas and other issues, to achieve the effect of effective and efficient division method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 Welding repair evaluation method

[0044] As shown in the figure, the present invention provides a welding repair evaluation method, comprising the following steps:

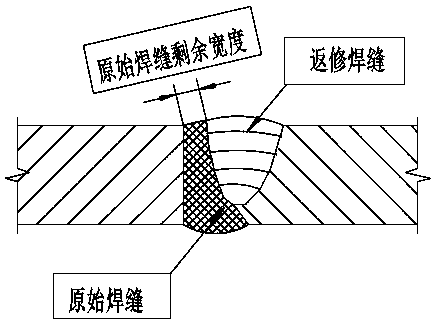

[0045] Step 1, first perform welding according to the qualified WPS, such as Picture 1-1 shown.

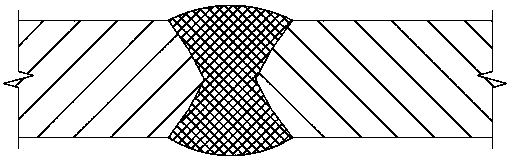

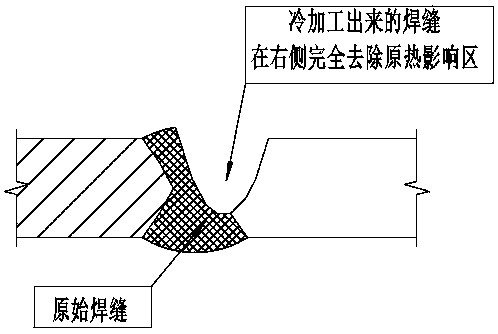

[0046] Step 2, using cold working methods, such as mechanical processing, to remove the weld seam and part of the heat-affected zone on one side of the original weld seam, and the heat-affected zone removed is the upper or middle upper part of the heat-affected zone on one side;

[0047] However, some remaining original welds must be guaranteed.

[0048] Such as Figure 1-2 shown. The preferred solution is: according to different rework welding methods, determine different residual amounts. For example, with GTAW rework, a minimum of 6mm remains of the original weld. Use SMAW, FCAW, GMAW for rework, with at least 8mm remaining of the original weld. Prevent the original heat-affected zone fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com