3D forming integrated on-line dynamic balance terminal

A terminal and 3D technology, applied in the direction of large fixed members, automatic control devices, vibration suppression adjustment, etc., can solve the problems of reducing the sealing performance of the balance cavity of the dynamic balance terminal, increasing the quality of the dynamic balance terminal, and the complex structure of the dynamic balance terminal. Achieve the effects of reducing additional mass, simplifying structure, and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

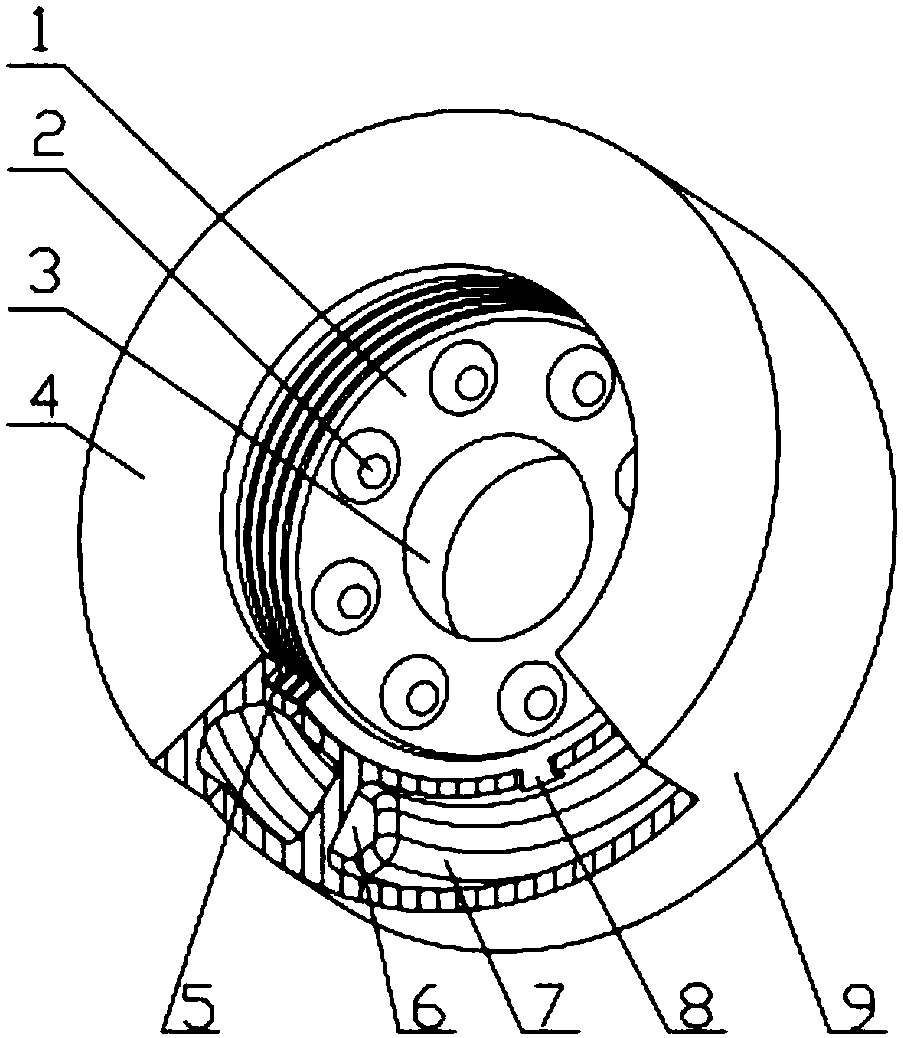

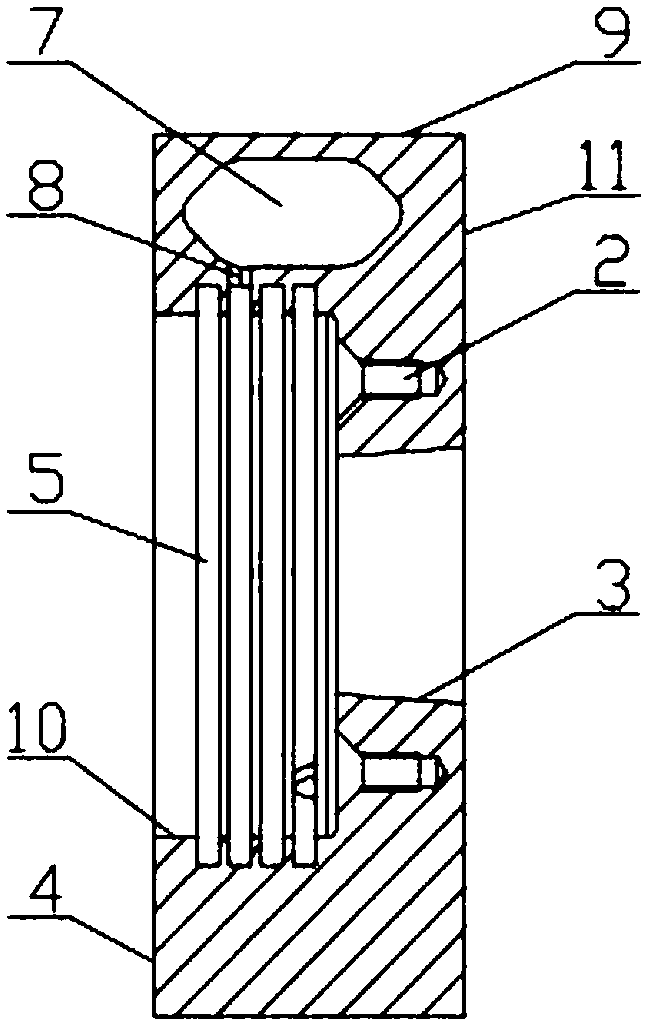

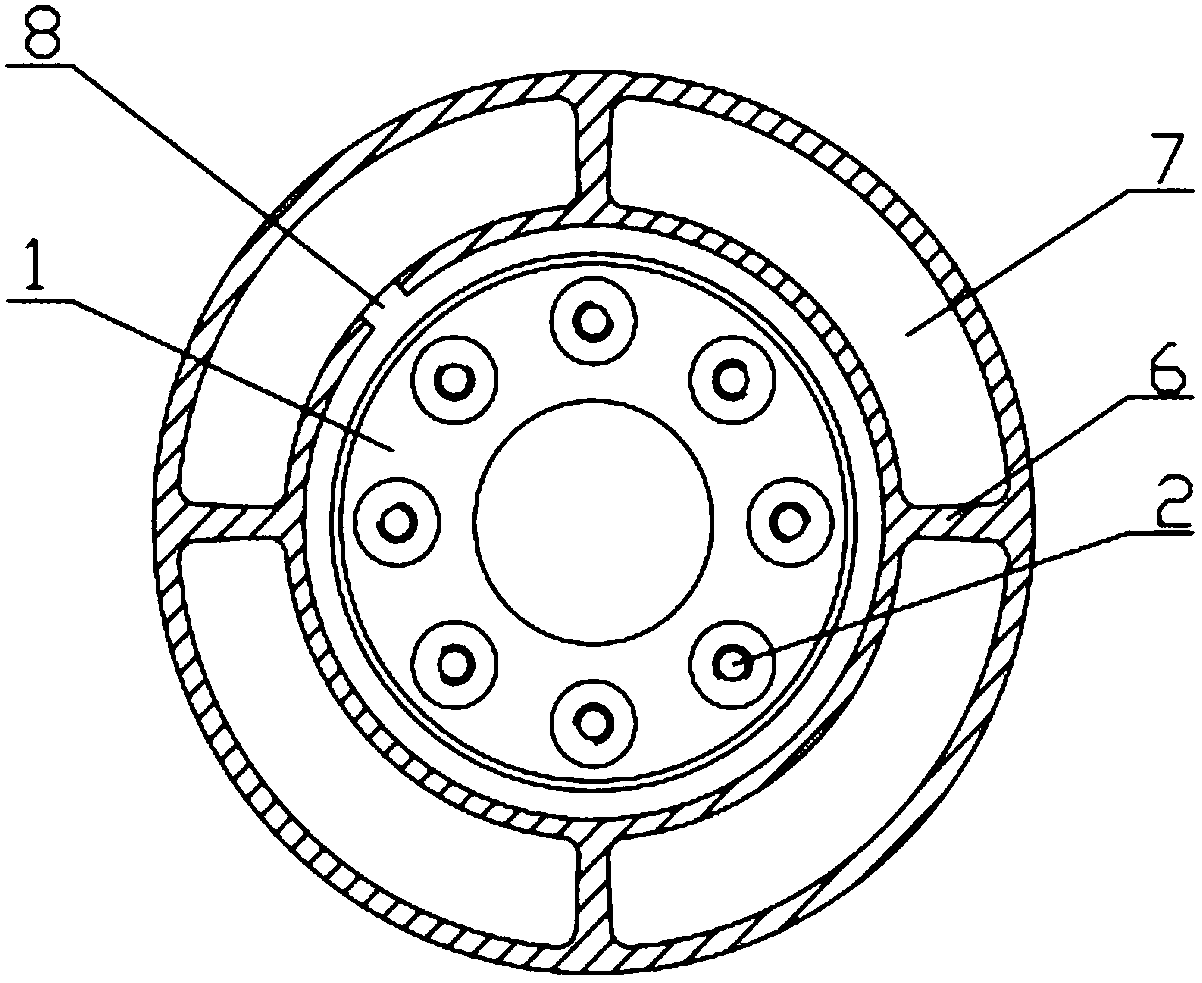

[0020] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , a 3D-formed integrated online dynamic balance terminal, the bottom of the integrated online dynamic balance terminal is provided with a central tapered hole 3, and the integrated online dynamic balance terminal is socketed on the main shaft 13 through the central tapered hole 3; the integrated online dynamic balance terminal Inside the dynamic balance terminal, there are four balance chambers 7 with the same shape evenly distributed along the circumference. The inner circular end face 10 of the balance terminal is designed with four equidistant liquid guide grooves 5 along the axial direction. The four liquid guide grooves 5 communicate with the corresponding balance chambers 7 through trapezoidal holes 8, and the liquid injected from the outside into the liquid gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com