Concrete admixture and preparation method thereof

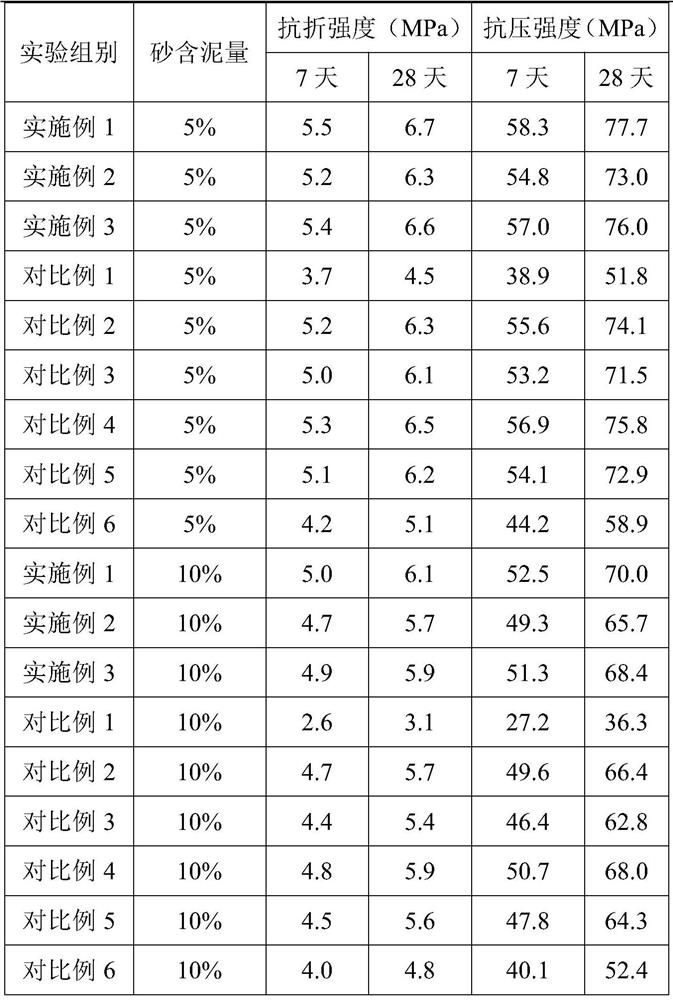

A technology of concrete admixture and water reducing agent, applied in the field of building materials, can solve the problems of unsatisfactory enhancement effect of concrete flexural strength and compressive strength, and achieve the effect of improving flexural strength and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] For the preparation of silica-coated titanium dioxide, refer to the content disclosed in paragraph 0041 of CN104045266B.

[0028] The preparation method of described concrete admixture comprises the following steps:

[0029] (1) Get the flue deposit, grind the deposit into fine powder, put it into water 4 times the mass of the deposit, ultrasonicate for 30min, then filter and dry to obtain the pretreated flue deposit;

[0030] (2) Preparation of cellulose-grafted chitosan: add cellulose to distilled water, stir and disperse, pass through nitrogen for 30 minutes to remove oxygen, then add potassium persulfate solution under nitrogen protection, pretreat at 55 ° C for 2 hours, and then Add a 1wt% acetic acid solution of chitosan dissolved in a crosslinking agent, react at 50°C for 4h, wash with water to remove water-soluble impurities, then put the product into 1wt% acetic acid solution for extraction for 24h and continue to remove the homopolymer. Then wash with water a...

Embodiment 1

[0034]A concrete admixture, in parts by weight, comprising the following raw materials: 45 parts of polycarboxylate water reducer, 16 parts of cellulose grafted chitosan, 16 parts of pretreated flue deposits, vinyl triethylene 6 parts of oxysilane, 3 parts of polyvinylpyrrolidone, 2 parts of silicon carbide, 5 parts of hollow glass microspheres, 8 parts of silicon dioxide coated titanium dioxide, 5 parts of gelatin powder, 3 parts of calcium stearate, 3 parts of polyferric sulfate 6 parts, 6 parts of high alkali glass fiber.

[0035] For the preparation of silica-coated titanium dioxide, refer to the content disclosed in paragraph 0041 of CN104045266B.

[0036] The preparation method of described concrete admixture comprises the following steps:

[0037] (1) Get the flue deposit, grind the deposit into fine powder, put it into water 4 times the mass of the deposit, ultrasonicate for 30min, then filter and dry to obtain the pretreated flue deposit;

[0038] (2) Preparation of...

Embodiment 2

[0041] A concrete admixture, in parts by weight, comprising the following raw materials: 50 parts of polycarboxylate water reducer, 15 parts of cellulose grafted chitosan, 20 parts of pretreated flue deposits, vinyl triethylene 5 parts of oxysilane, 1 part of polyvinylpyrrolidone, 5 parts of silicon carbide, 3 parts of hollow glass microspheres, 10 parts of silicon dioxide coated titanium dioxide, 2 parts of gelatin powder, 1 part of calcium stearate, 1 part of polyferric sulfate parts, 10 parts of high alkali glass fiber.

[0042] For the preparation of silica-coated titanium dioxide, refer to the content disclosed in paragraph 0041 of CN104045266B.

[0043] The preparation method of described concrete admixture comprises the following steps:

[0044] (1) Get the flue deposit, grind the deposit into fine powder, put it into water 4 times the mass of the deposit, ultrasonicate for 30min, then filter and dry to obtain the pretreated flue deposit;

[0045] (2) Preparation of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com