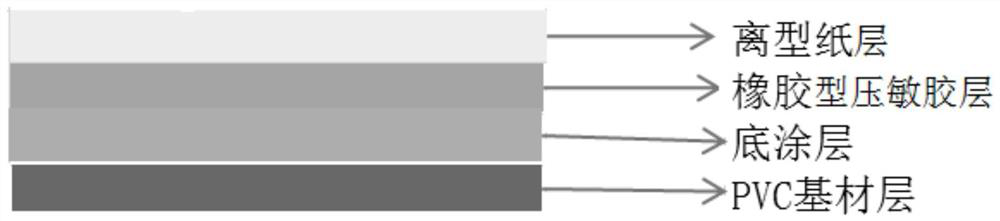

A kind of high-performance PVC anti-coating film for flexible circuit board and its preparation method and application

A flexible circuit board, high-performance technology, used in pressure-sensitive films/sheets, film/sheet release coatings, polymer adhesive additives, etc. and other problems, to achieve the effect of good solvent resistance and adherence, saving production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

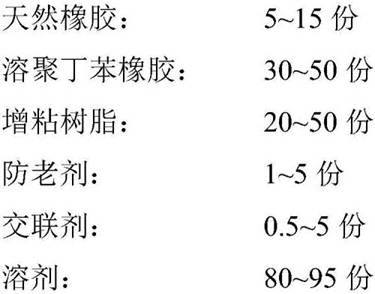

Method used

Image

Examples

Embodiment 1

[0046](a) The preparation method of high-performance PVC anti-coating film is as follows:

[0047] (1) Mix the raw materials of the bottom coating according to the proportion, stir evenly, pour it into the bottom rubber tank, and use a 110-mesh anilox roller to coat the thickness of 75 microns and the hardness of 36 produced by Guangzhou Nanya Plastic Co., Ltd. On the blue PVC film, pass through an oven with a length of 4 meters and bake at 50°C for 12 seconds to form a primer layer of 0.3-0.5 microns.

[0048] The base coat is composed of the following components in parts by weight:

[0049] Solution polystyrene butadiene rubber 1205: 30 parts

[0050] Dibenzoyl peroxide: 0.8 parts

[0051] Toluene: 69.2 parts.

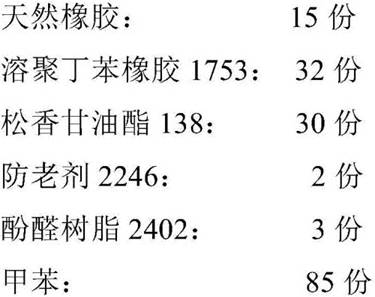

[0052] (2) Stir and mix the rubber-type pressure-sensitive adhesive layer raw materials in a closed stirring reaction kettle for 8 hours, pump it out after fully dissolving, filter it into the glue tank with a 100-mesh nylon filter, and apply it on the On the und...

Embodiment 2

[0062] (a) The preparation method of high-performance PVC anti-coating film is as follows:

[0063] (1) Mix the raw materials of the bottom coating according to the ratio, stir evenly, pour it into the bottom rubber tank, and use a 110-mesh anilox roller to coat the thickness of 70 microns produced by Guangzhou Nanya Plastic Co., Ltd., with a hardness of 34 On the blue PVC film, pass through an oven with a length of 4 meters, bake at 50°C for 12 seconds, and form a primer layer of 0.3-0.5 microns;

[0064] The base coat is composed of the following components in parts by weight:

[0065] Solution polystyrene butadiene rubber 1205: 30 parts

[0066] Dibenzoyl peroxide: 1 part

[0067] Toluene: 69.2 parts.

[0068] (2) Stir and mix the rubber-type pressure-sensitive adhesive layer raw materials in a closed stirring reaction kettle for 8 hours, pump it out after fully dissolving, filter it into the glue tank with a 100-mesh nylon filter, and apply it on the On the undercoat l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com