A combined process method for producing needle coke by mixing raw materials

A process method and technology for mixing raw materials, which can be used in hydrotreating process, petroleum industry, treatment of hydrocarbon oil, etc., can solve the problems of large thermal expansion coefficient and low yield of needle coke, and achieve excellent performance, improve raw material properties and effects. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

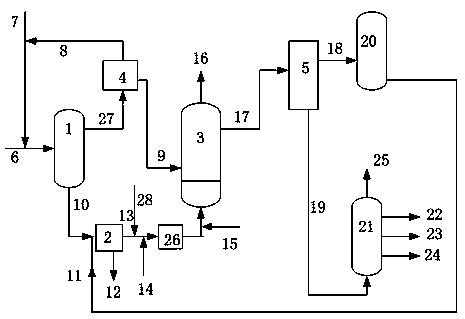

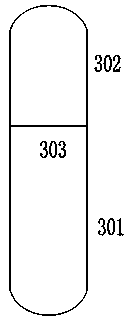

Method used

Image

Examples

Embodiment 1

[0043] The raw materials in Example 1 are catalytic oil slurry and coal tar raw materials, and their properties are shown in Table 1. The blending ratio of catalytic oil slurry and coal tar heavy component (referred to as mixed raw material) is 1:1, and the auxiliary agent is lignin, lignin The mixing ratio with mixed raw materials is 0.1:1, the reaction temperature of supercritical extraction of coal tar is 220°C, the pressure is 6Mpa, the extraction agent is CO2, and the extraction ratio is 0.3.

Embodiment 2

[0045] Example 2 is the same as Example 1, the raw materials are catalytic oil slurry and coal tar raw material, the blending ratio of catalytic oil slurry and coal tar heavy component (referred to as mixed raw material) is 0.5:1, and other conditions remain unchanged.

Embodiment 3

[0047] In Example 3, the raw materials are catalytic oil slurry and coal tar raw materials, the blending ratio of catalytic oil slurry and coal tar heavy component (referred to as mixed raw materials) is 1:1, the auxiliary agent is lignin, and the blending of lignin and mixed raw materials The ratio is 0.2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com