Preparation method of spinning structure thermoelectric conversion device

A technology of thermoelectric conversion devices and textile structures, which is applied in the manufacture/processing of thermoelectric devices, thermometers using directly heat-sensitive electrical/magnetic components, and textiles, etc., can solve uneven structure control, single variety, and high low cost Efficiency and other issues, to achieve the effect of a wide range of application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

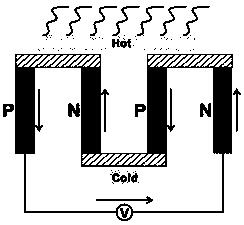

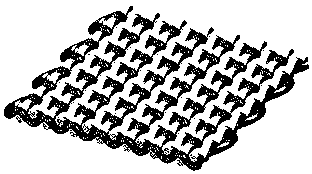

[0020] figure 2 It is a schematic diagram of a thermoelectric fabric in Example 1 of the present invention. The thermoelectric fabric in this example is a plain weave structure. The insulating warp yarns are arranged on the small prototype machine along the fabric forming direction, and a PN type thermoelectric yarn and an insulating yarn are introduced alternately. The thread is used as the weft yarn, and the desired fabric is formed after several cycles, such as figure 2 As shown, a constant current is generated by applying a temperature difference in the thickness direction of the fabric

[0021] In this embodiment, the forming looms used include but are not limited to small prototype looms; the yarns used are all soft, strong and weavable yarns.

Embodiment 2

[0023] image 3 It is a schematic diagram of a thermoelectric fabric in Example 2 of the present invention. The textile structure thermoelectric power generation material in this example is a weft-knitted structure, using P-type thermoelectric yarns, N-type thermoelectric yarns, insulating yarns and thermoelectric yarns. P The type thermoelectric yarn and the N type thermoelectric yarn are alternately fed into the crochet needles of the knitting machine, and the desired fabric is formed after several cycles. Insulating and thermoelectric yarns are introduced after weaving. A constant current is generated by applying a temperature difference in the thickness direction of the fabric.

[0024] In this embodiment, the fabric forming mechanisms used include but should not be limited to knitting machines; the yarns used are all soft, strong and weavable yarns; on the one hand, the insulating yarns bear the transition of part of the temperature difference, and more importantly, To ...

Embodiment 3

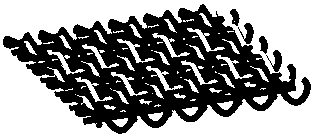

[0026] Figure 4 It is a schematic diagram of the thermoelectric fabric structure of the third embodiment of the present invention. The textile structure thermoelectric power generation material in this embodiment is a three-dimensional orthogonal three-dimensional woven structure. Figure 4 This is a schematic diagram of the yarns used in this example. The insulating warp yarns are arranged on the three-dimensional loom according to a certain warp density along the fabric forming direction, and a PN type thermoelectric yarn and insulating weft yarn are sequentially introduced. The number of weaving cycles is controlled according to the desired fabric length to obtain the desired fabric. A constant current is generated by applying a temperature difference across the thickness of the fabric.

[0027] In this implementation example, the fabric forming mechanism used should include but not limited to a three-dimensional loom; the yarns used are all soft, have a certain strength ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com