Bridge engineering 3D printing device and construction method

A 3D printing and bridge engineering technology, used in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as error accumulation, difficult formwork, rough surface, etc., to achieve convenient movement, solve low efficiency, and achieve accurate printing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

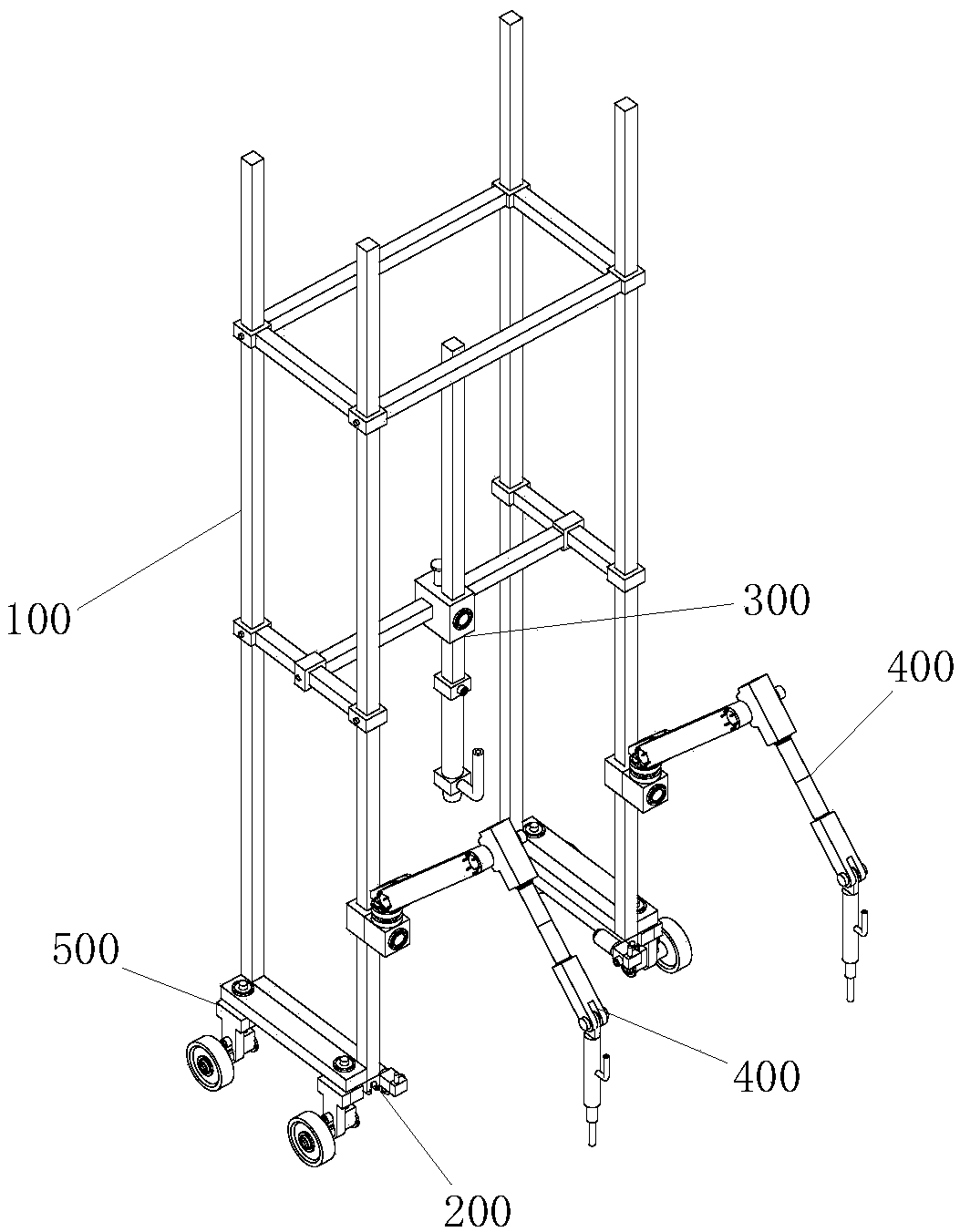

[0047] see figure 1 , the bridge engineering 3D printing device in this embodiment includes a guide frame 100 , a guide rail traveling mechanism 200 , a bridge 3D printing mechanism 300 and a track 3D printing mechanism 400 .

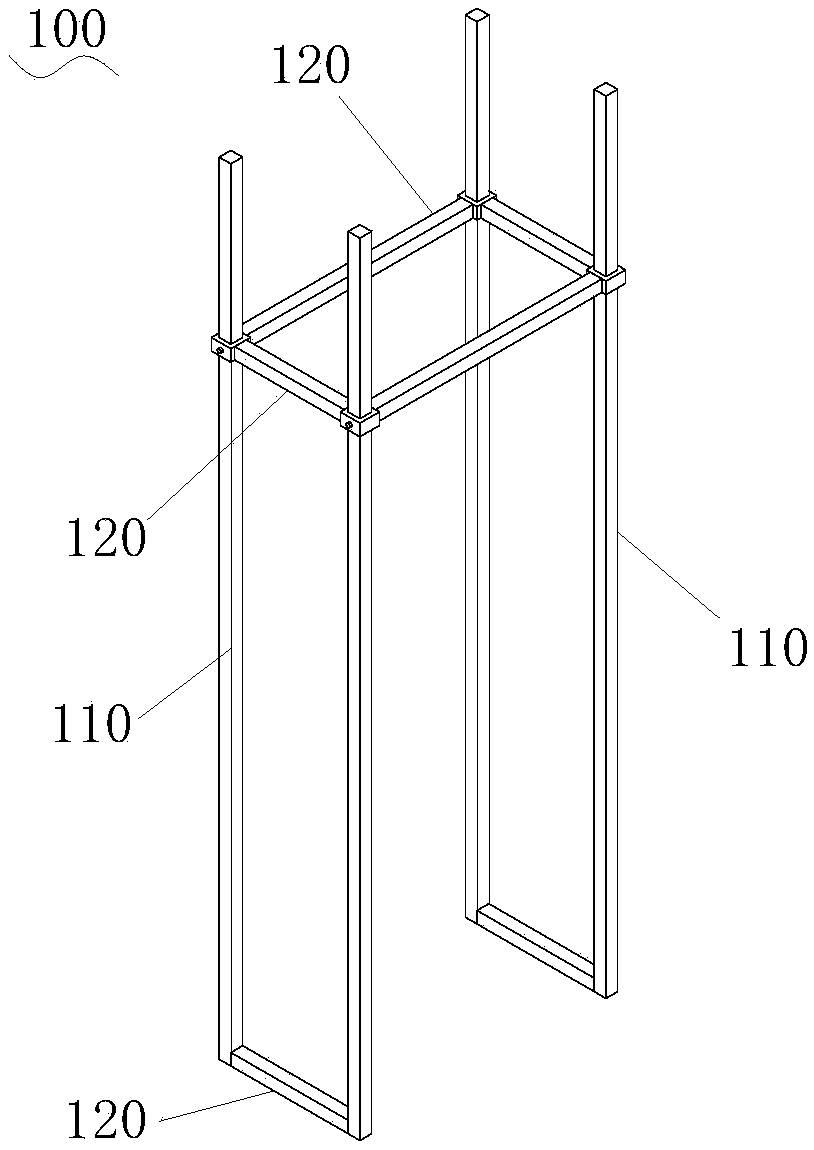

[0048] combine figure 1 with figure 2 As shown, the guide frame 100 includes four vertical guide rails 110 and a plurality of horizontal rods 120 arranged between the vertical guide rails 110, and the vertical guide rails 110 and the horizontal rods 120 form a frame structure. The guide frame 100 is used to fix and support the bridge 3D printing mechanism 300 and the track 3D printing mechanism 400 , and the bridge 3D printing mechanism 300 and the track 3D printing mechanism 400 can move up and down along the vertical guide rail 110 .

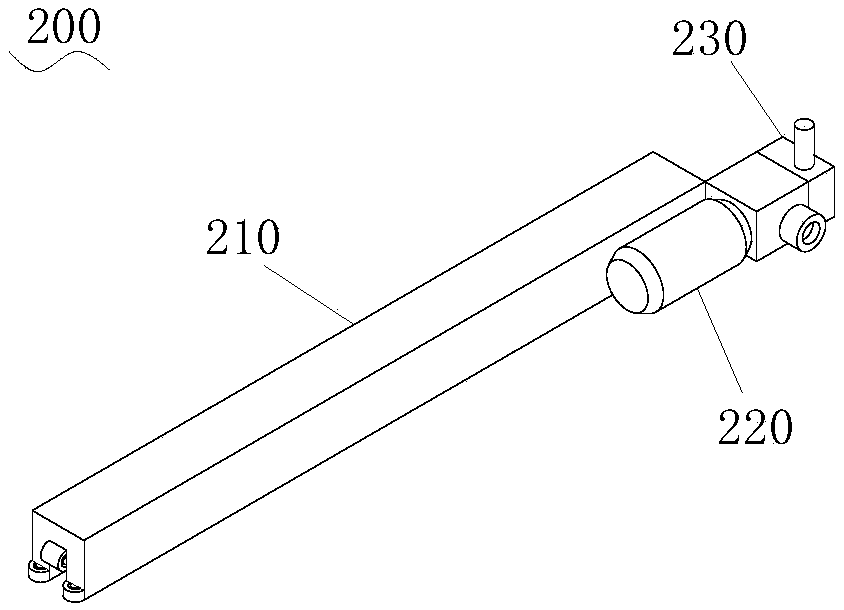

[0049] combine figure 1 with image 3 As shown, the top of the guide rail traveling mechanism 200 is fixedly connected to the bottom of the guide frame 100, and the bottom is arranged on a horizontally arranged tra...

Embodiment 2

[0055] This embodiment provides a construction method of the bridge engineering 3D printing device in Embodiment 1, combined below Figure 1 to Figure 8 As shown, the construction method is further introduced. The construction method specifically includes the following steps:

[0056] S1. Assemble the 3D printing device and transport it to the area to be constructed. Assembling the 3D printing device specifically includes: fixing the vertical guide rail 110, and fixing the horizontal bar 120 to form the guide frame 100 of the frame structure; installing the guide rail running mechanism 200 at the bottom of the guide frame 100; fixing the space displacement assembly 310 on the vertical guide rail 110, and then Fix the printing head one 320 on the spatial displacement component 310 to complete the installation of the bridge 3D printing mechanism 300; install the mechanical arm rotation base 410, the mechanical arm 420 and the printing head on the vertical guide rail 110 near th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap