Composite wallboard

A technology of composite wall panels and splints, which is applied to building components, buildings, building structures, etc., can solve problems such as product strength limitations, and achieve the effects of reducing weight, saving resources, and reducing land damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

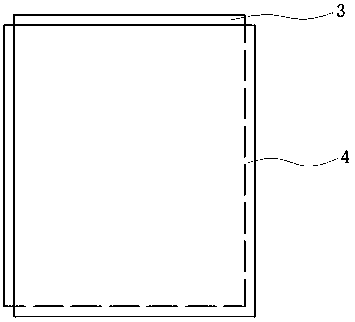

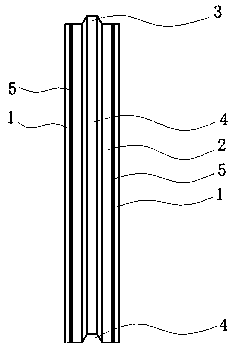

[0019] A composite wall panel such as figure 1 and figure 2 As shown, it includes two layers of plywood 1 made of fiber cement or calcium silicate, and a middle layer core board 2 made of polyphenylene particle bonded mortar is arranged between the plywood boards 1, and the adjacent middle layer core board 2 A protruding groove 3 for assembly is provided on the side, and a groove 4 matching the protruding groove is provided on the adjacent two sides, and the thickness of the splint 1 is not more than 8mm.

[0020] Based on the design principles of the above specific embodiments, in another specific embodiment, an adhesive layer 5 for bonding is also provided between the splint 1 and the middle core board 2 . This design method can effectively ensure that the plywood and the middle core board are bonded together. In one specific embodiment, the bonding layer is made of concrete.

[0021] Based on the design principles of the above specific embodiments, in one specific embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com