Environment-friendly core drilling method for complex sandy cobble stratum

A kind of sand and pebble, environmental protection technology, applied in the field of exploration and coring, can solve the problems of large broken particles and dust, the health impact of construction environment operators, etc., to achieve the effect of good meshing, easy transportation and strong application function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

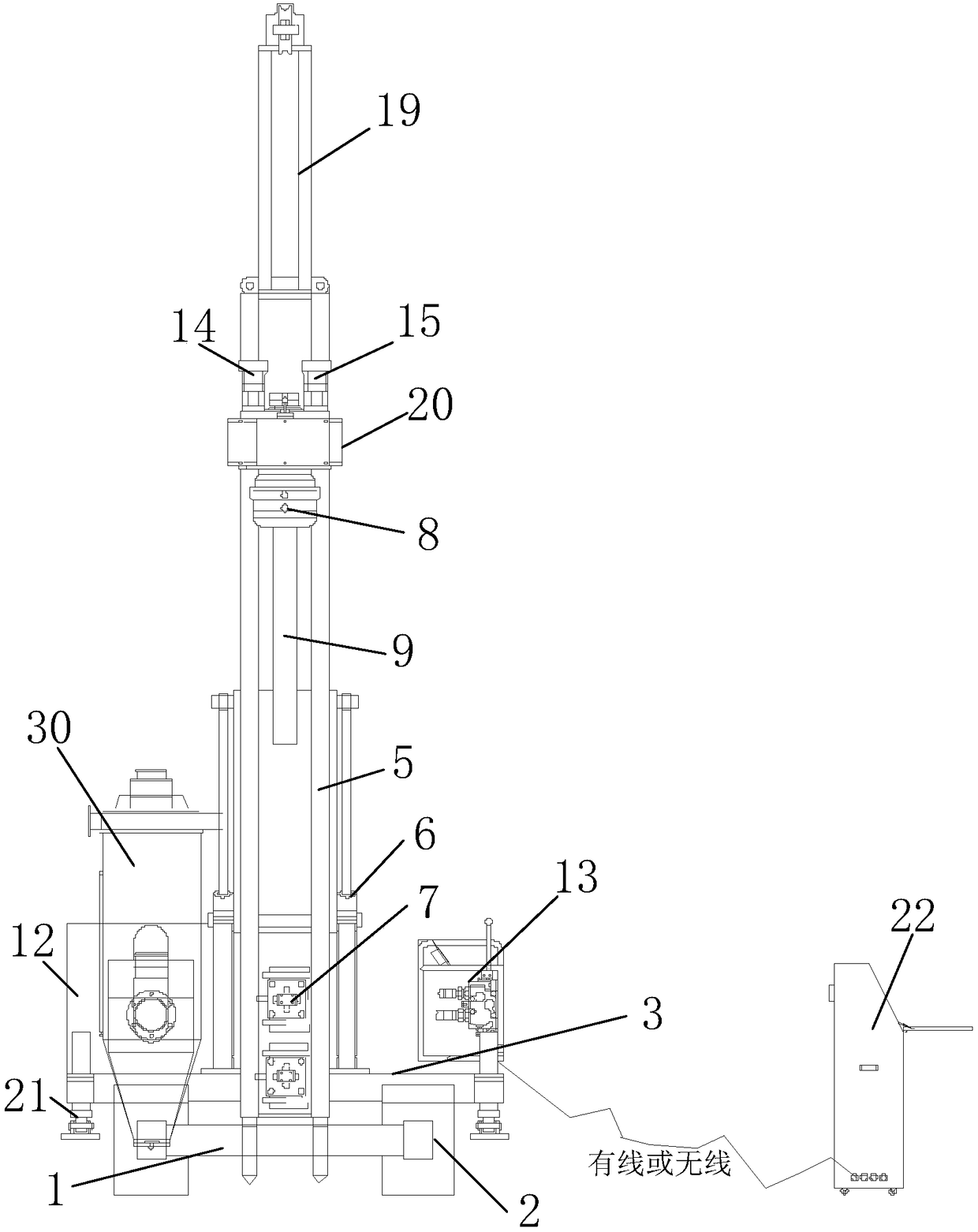

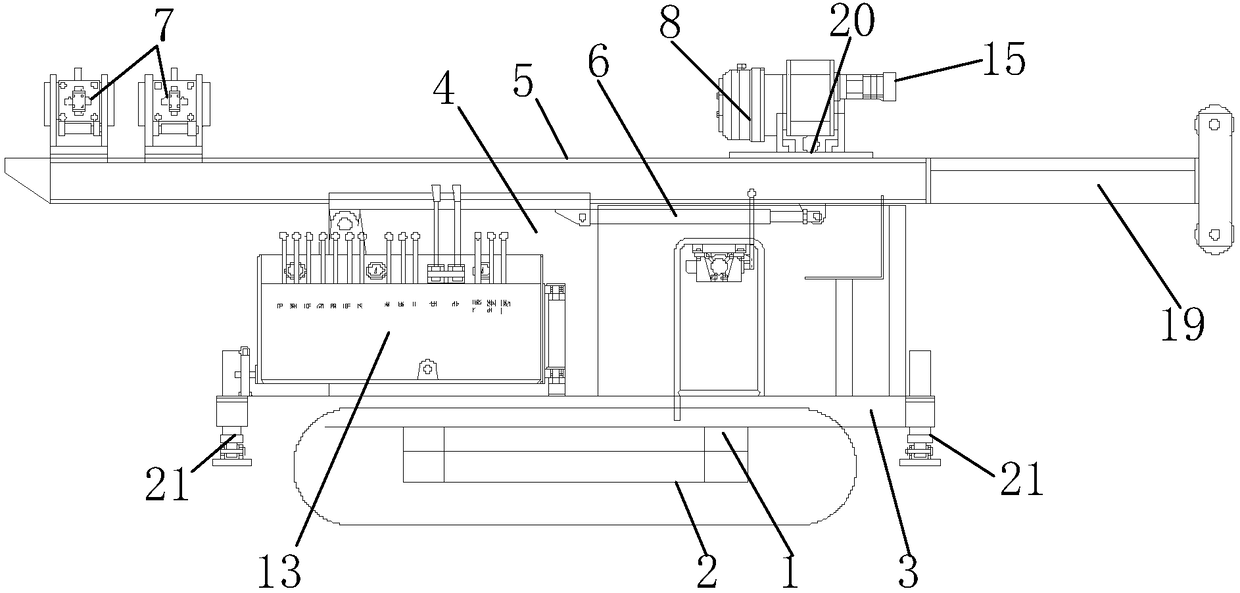

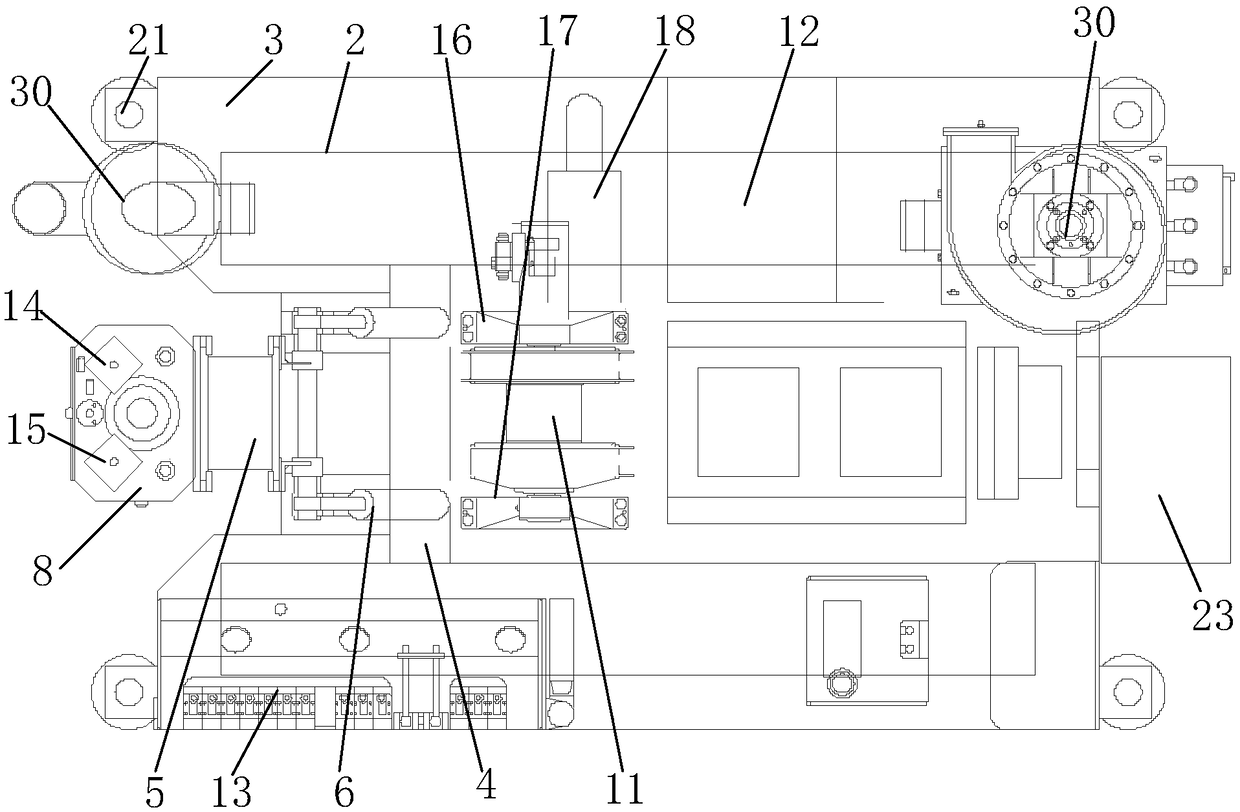

[0047] Such as Figure 1 to Figure 8 As shown, the environment-friendly drilling coring machine includes a chassis 1 with a crawler-type walking mechanism 2, an operating platform 3 arranged on the chassis, a mast frame 4 arranged in the middle of the operating platform, and a flip-type hinged front part of the mast frame. Mast 5, a mast lift cylinder 6 whose fixed end is hinged to the mast frame and whose movable end is hinged to the flip-type mast, a shackle chuck 7 arranged at the front end of the flip-type mast, and a drilling rig which is installed in the middle of the flip-type mast and can move along it Power head 8, the drilling rod 9 that is installed on the drilling rig power head, the sleeve pipe 10 that cooperates with drilling rod 10, is arranged on the operation platform and by the hoist 11 that is connected with the drilling rig power head by cable around the overturning mast, and is arranged on The diesel engine 12 that provides power for the drilling rig on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com