Offshore natural gas liquefying system

A natural gas and cryogenic technology, applied in the field of FLNG systems, can solve problems such as high energy consumption, poor economy, and poor adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

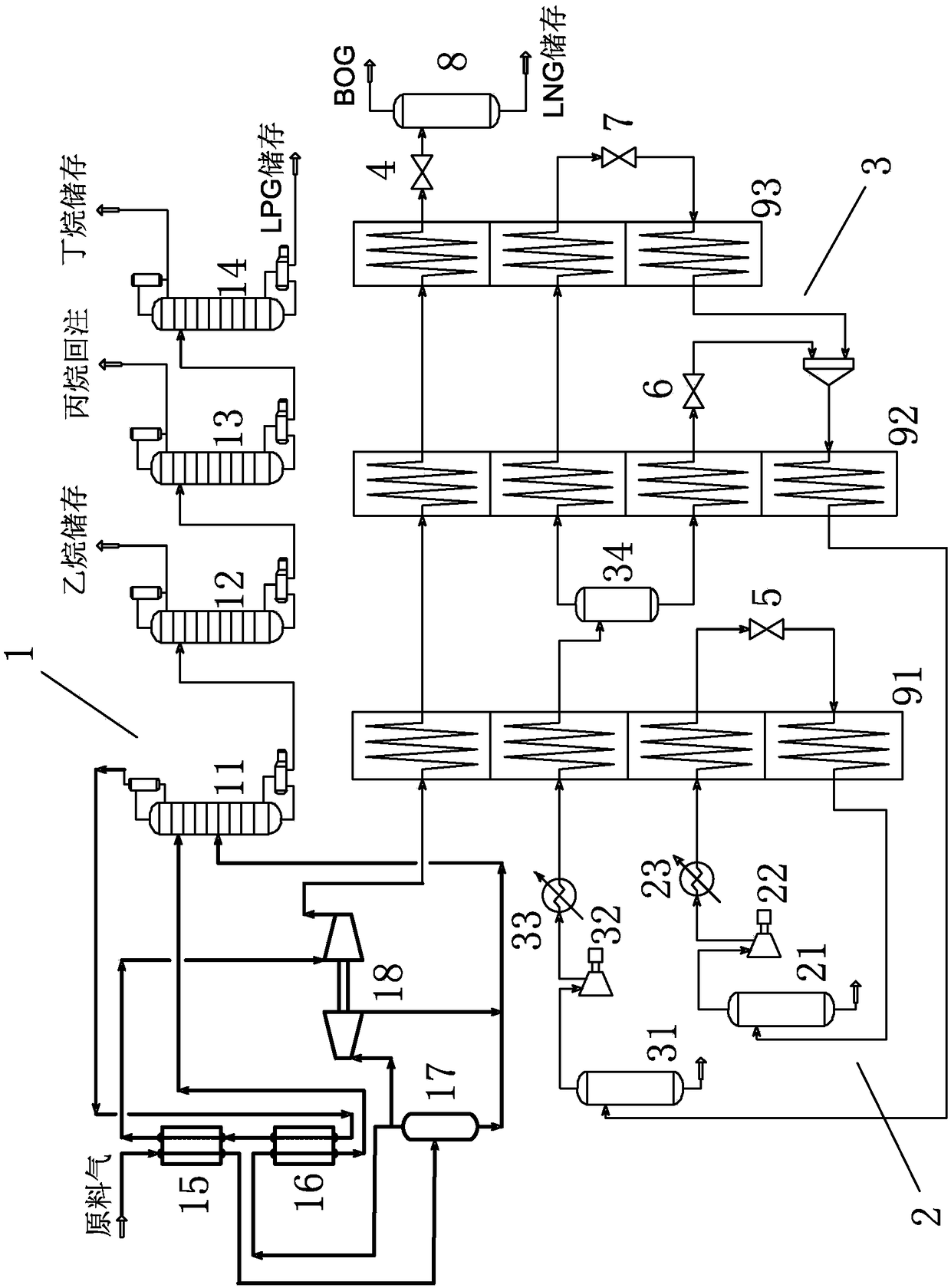

[0021] like figure 1 As shown, the present invention provides a natural gas liquefaction system suitable for use at sea, which includes a light hydrocarbon separation device 1, a mixed refrigerant precooling cycle 2, a precooling main low-temperature heat exchanger 91, a mixed refrigerant cryogenic cycle 3, a No. 9 cryogenic main low-temperature heat exchanger 92 and No. 2 cryogenic main low-temperature heat exchanger 93, wherein:

[0022] The light hydrocarbon separation device 1 mainly includes a demethanizer 11, a deethanizer 12, a depropanizer 13 and a debutanizer 14 connected in sequence, which can sequentially remove methane, ethane, propane and butane in natural gas , the top of the deethanizer 12 is connected to an ethane storage tank, and the top and bottom of the debutanizer 14 are respectively connected to a butane storage tank and a condensate storage tank. The present invention does not set propane storage, The mole fraction of propane in the top product of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com