Insulator leakage current and zero value detection device

A leakage current and zero-value detection technology, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, can solve the problems of inability to carry out live operation, quantitative analysis, and heavy detection workload, etc., to achieve live detection, structure Simple, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The core of the invention is to provide an insulator leakage current and zero value detection device, which has a simple structure and is easy to use, and can realize live detection of insulator voltage signals and current signals.

[0039] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

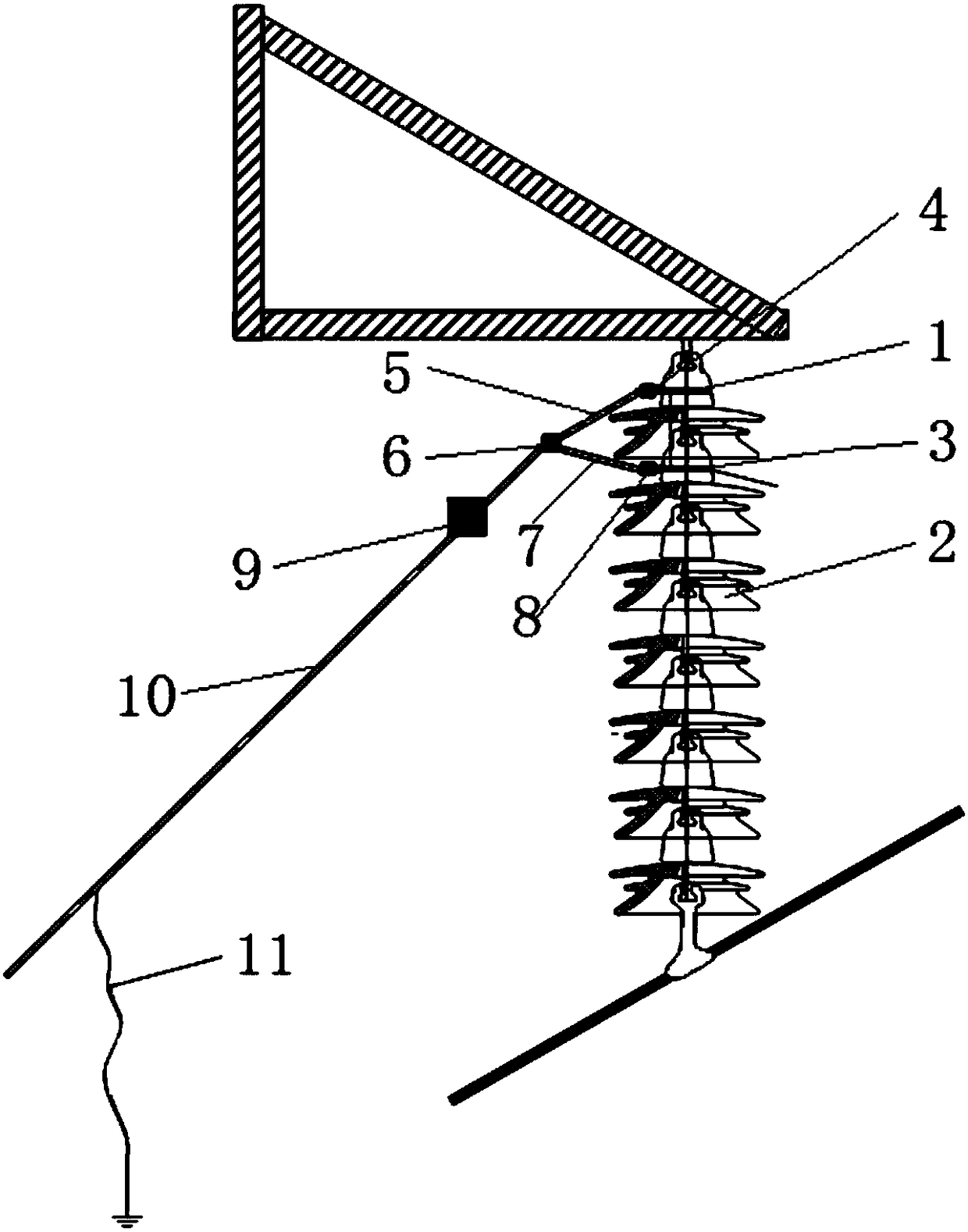

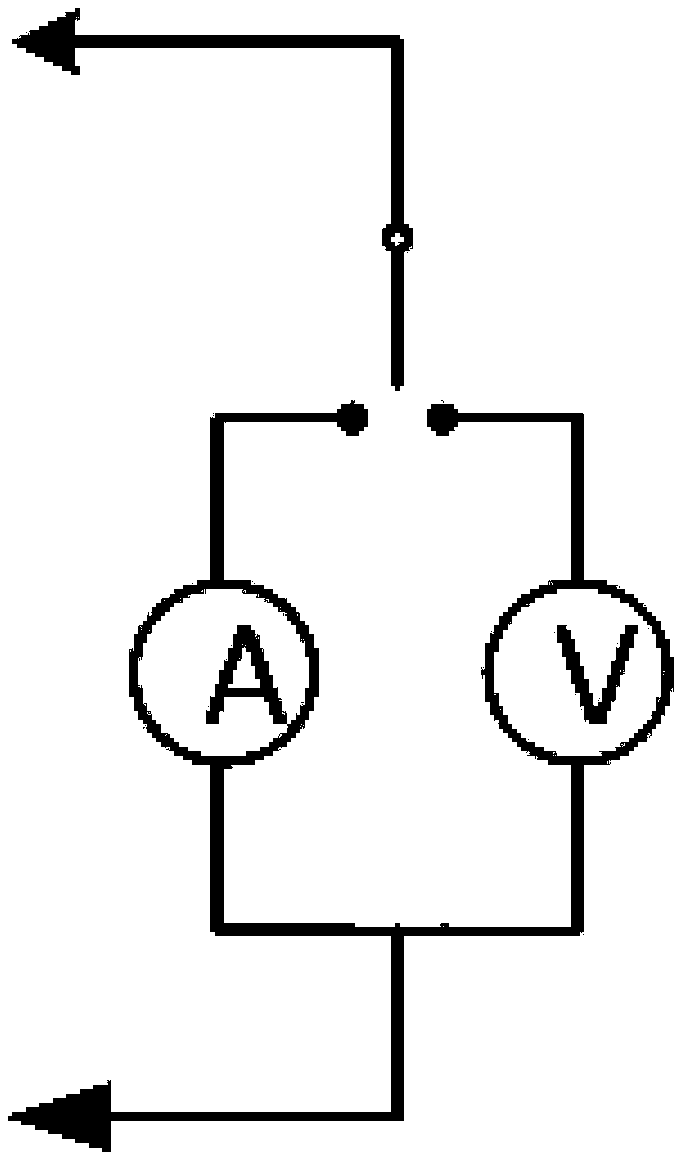

[0040]The present invention provides an insulator leakage current and zero value detection device, including an insulating rod 10, the insulating rod 10 is made of insulating material, and the insulating rod 10 should have good insulation to ensure the personal safety of live workers, preferably It is made of glass fiber reinforced plastic epoxy resin insulating rod, or made of rubber material; the top end of the insulating rod 10 is equipped with a clamping assembly for clamping two insulators 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com